|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

Model Number: |

YQ32-315T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

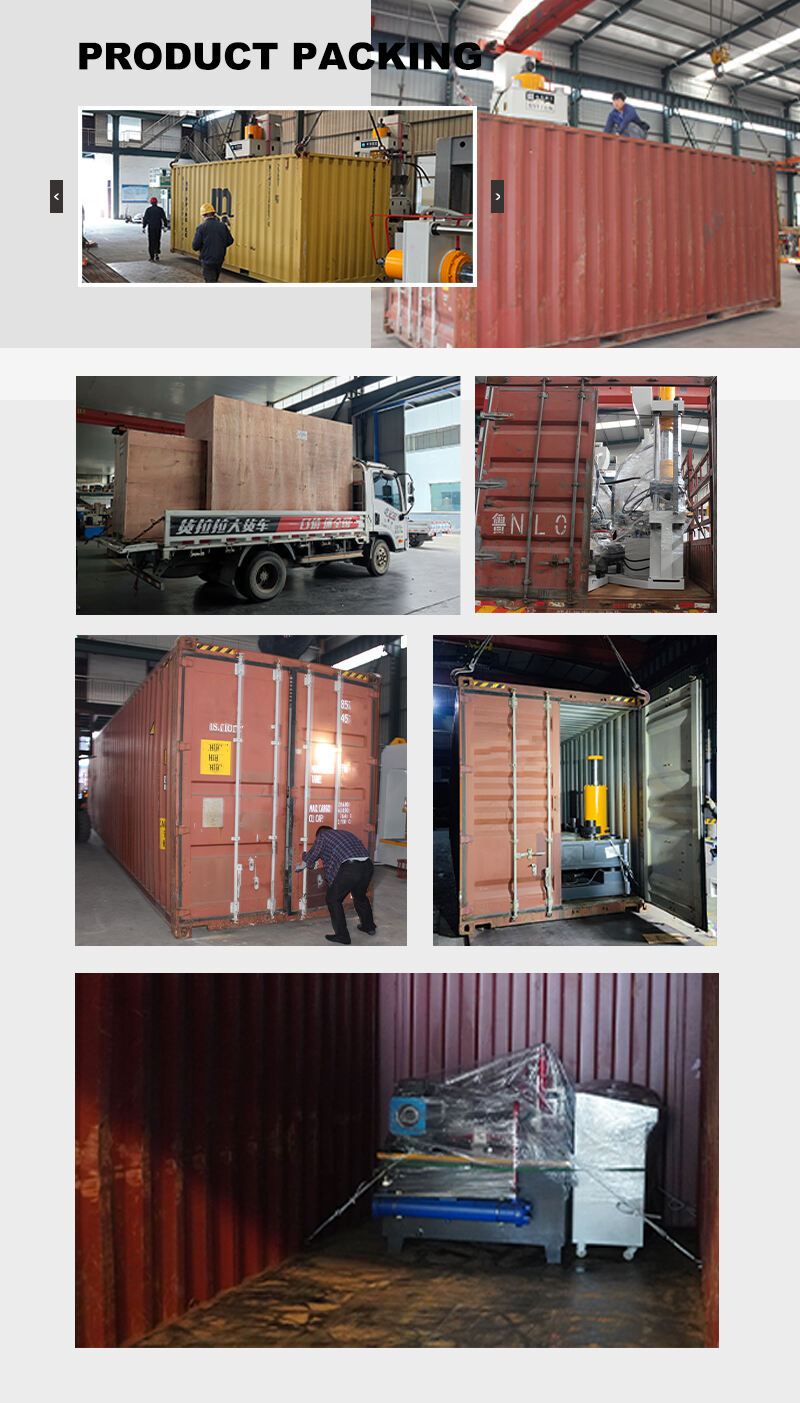

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

315 ton hot press machine" is a kind of hot press molding equipment with a nominal pressure of 315 tons, which is used for molding plastic and other composite products.Firstly, the plastic raw material is melted through the extruder, and then the melted plastic mass is put into the mold for pressing, and the composite material molding is completed under high pressure and medium high temperature.Its core function is to apply high pressure through hydraulic or mechanical system and combined with heating to make the material (such as plastic, rubber, composite material, wood, metal powder, etc.) undergo plastic deformation or curing reaction, and finally made into a specific shape of the product.

Three-beam and four-column frame: composed of upper crossbeam, lower crossbeam, slider and four columns, with strong structural rigidity and deformation resistance.

Suitable for high-precision and high-load pressing process to ensure the stability of plastic large basin molding size.

Cartridge valve integrated hydraulic system: reduce piping connections, reduce the risk of leakage, fast system response.

Small hydraulic shock, prolonging the service life of the equipment and low maintenance cost.

Independent electrical control system: adopting PLC programmable controller, supporting manual, semi-automatic and automatic operation modes.

Equipped with the functions of fixed-range and fixed-pressure molding, pressure preservation delay, emergency stop, etc., the operation is safe and flexible.

Humanized design: the operation panel is centrally arranged and the buttons are clearly marked, which is convenient for workers to get started quickly.

Parameters such as slider stroke and pressing speed can be adjusted according to the process demand, adapting to multi-species production.

1.Plastic Processing

Sheet/sheet molding: pressed PVC rigid board, PE/PP corrugated board, acrylic board, etc;

Molded products: automotive interior parts (instrument panels, door panels), industrial plastic shells (such as corrosion-resistant tank liner), large plastic pallets, etc.

2. Rubber and elastomer

Vulcanization of rubber products: tire cord ply lamination, sealing rubber strips, rubber shock pads;

Industrial rubber parts: large rubber rollers (for printing presses, rolling mills), rubber seals.

3. Composite materials

Laminates/molded parts: glass fiber reinforced plastic, carbon fiber reinforced plastic, aramid fiberboard;

Thermosetting resin molding: epoxy resin matrix composites.

4. Powder metallurgy and ceramics

Metal powder pressing: carbide inserts, iron-based/copper-based powder metallurgy gears;

Ceramic billet molding: electronic ceramic substrates, precision ceramic structural components.

5. Wood processing

Manufacture of man-made boards: density boards, particle boards;

Reconstituted wood/integrated wood: splicing and pressing of large-size solid wood panels.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy