|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

Model Number: |

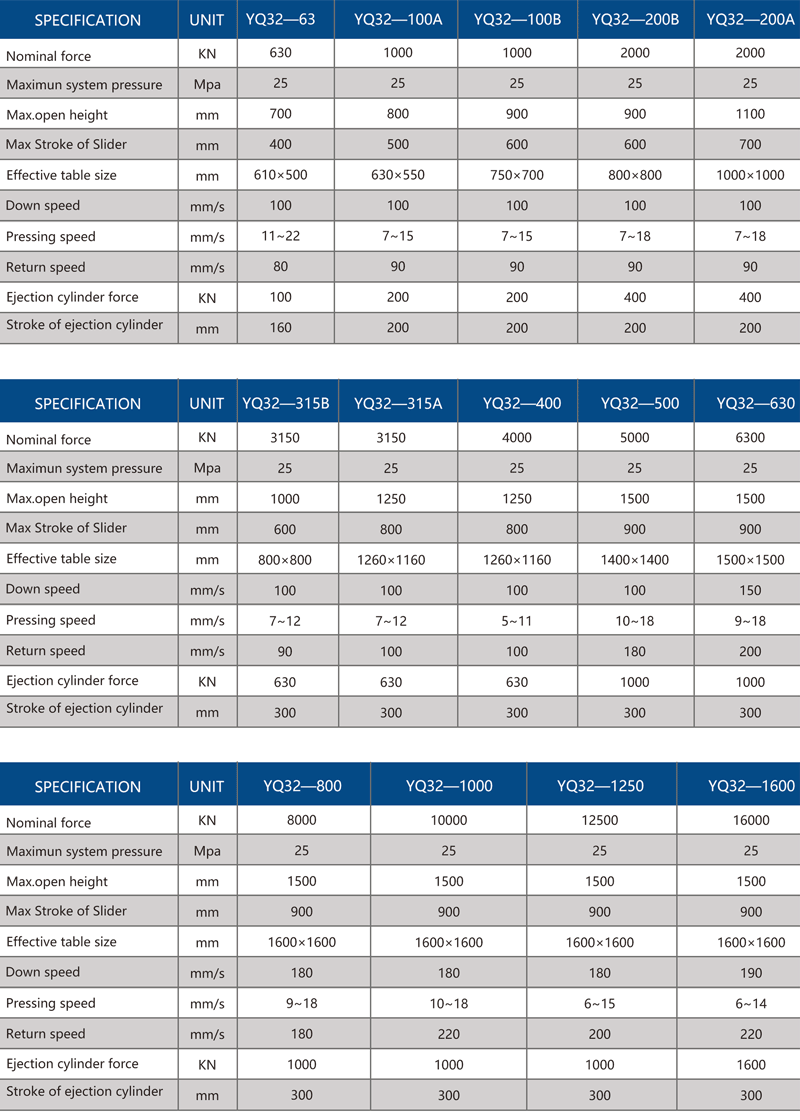

YQ32-500T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

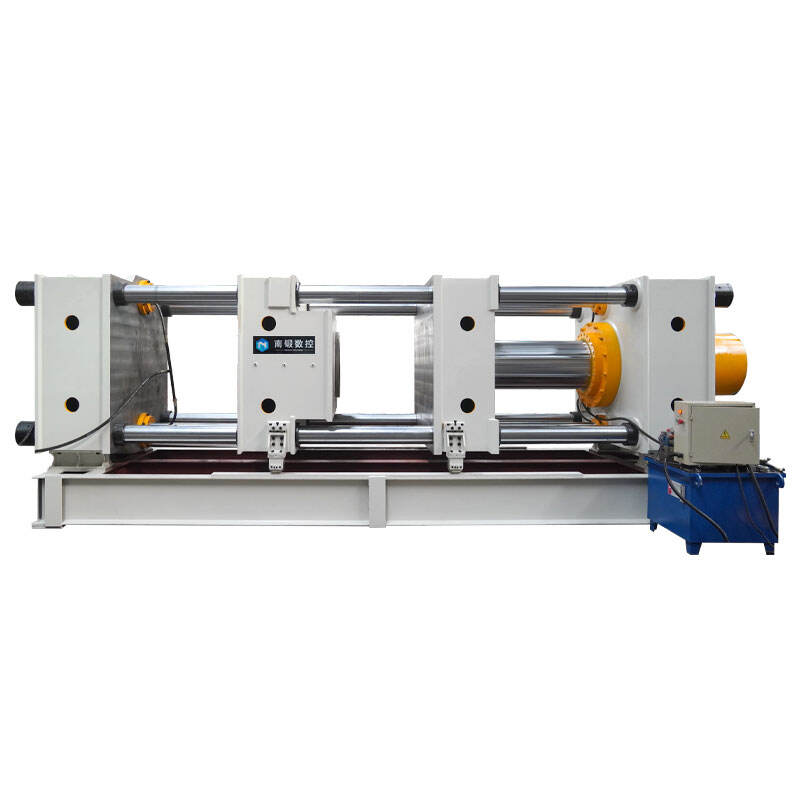

The 500-ton horizontal hydraulic press is a hydraulic forming machine with a nominal pressure of 5000 kilonewtons. Its defining feature is the horizontal movement of the piston rod in the main working cylinder, distinguishing it from common vertical hydraulic presses (where the cylinder moves vertically downward). This configuration makes it particularly suitable for processes involving long-length, horizontal press-fitting, disassembly, extrusion, and stretching operations.

Horizontal Layout: Compared to vertical presses, horizontal hydraulic presses are better suited for processing long-length workpieces or those subjected to horizontal forces, such as copper rods, copper tubes, and other elongated materials.

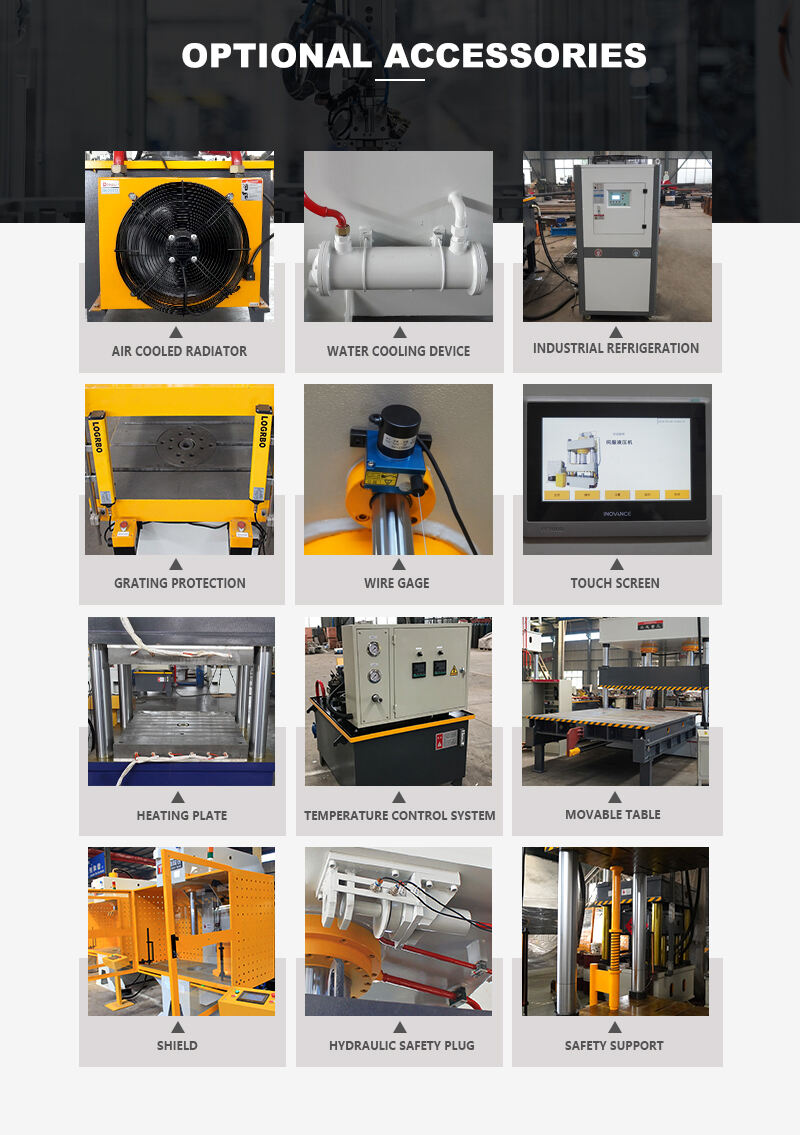

Electrical Control System: Supports relay control or PLC touchscreen control, enabling both constant pressure and constant stroke forming processes, with pressure-holding delay functionality.

Metal Processing Copper Alloy Extrusion: Produces copper rods, copper tubes, copper alloy radiator fins, etc., leveraging copper's high thermal conductivity to enhance equipment heat dissipation performance.

Stainless Steel Forming: Pressing stainless steel water tanks, sinks, etc., ensuring workpiece sealing and strength through hydraulic forming.

Metal Straightening: Straightening large shafts, round bars, and other components to eliminate deformation caused by machining or heat treatment.

Composite Material Forming Fiberglass Pressing: Producing fiberglass products (e.g., pipes, storage tanks) by achieving material densification through hydraulic forming.

Carbon Fiber Composite Molding: Widely used in aerospace, high-pressure forming ensures material performance.

Ceramic Powder Compaction: Produces high-precision components like ceramic bearings and cutting tools; hydraulic forming enhances material density and hardness.

Metal Powder Briquetting: Compresses scrap metal powders into blocks for efficient recycling.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy