|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

Model Number: |

YQ32-500T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

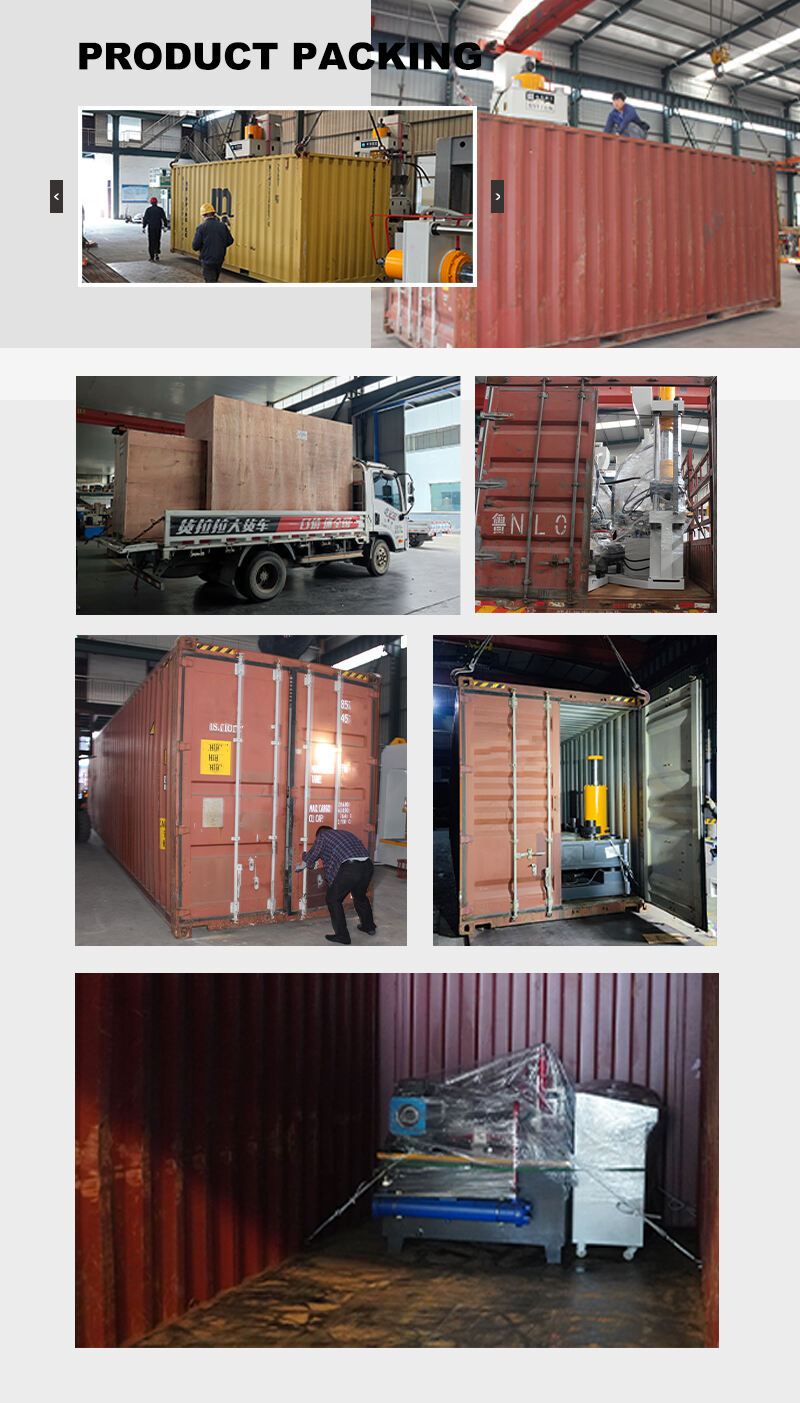

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

The 500-ton four-column hydraulic press is a common type of hydraulic molding equipment, which is widely used in metal processing, mold manufacturing, automotive parts and other fields.

|

YQ32 Technical Parameters |

||||||||

|

|

Unit |

YQ32—63 |

YQ32—100A |

YQ32—100B |

YQ32—200A |

YQ32—200B |

YQ32—315A |

YQ32—315B |

|

Nominal force |

KN |

630 |

1000 |

1000 |

2000 |

2000 |

3150 |

3150 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

700 |

800 |

900 |

900 |

1100 |

1000 |

1250 |

|

Max Stroke of Slider |

mm |

400 |

500 |

600 |

600 |

700 |

600 |

800 |

|

Effective table size |

mm |

610×500 |

630×550 |

750×700 |

800×800 |

1000×1000 |

800×800 |

1260×1160 |

|

Down speed |

mm/s |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Pressing speed |

mm/s |

11~22 |

7~15 |

7~15 |

7~18 |

7~18 |

7~12 |

7~12 |

|

Return speed |

mm/s |

80 |

90 |

90 |

90 |

90 |

90 |

100 |

|

Ejection cylinder force |

KN |

100 |

200 |

200 |

400 |

400 |

630 |

630 |

|

Stroke of ejection cylinder |

mm |

160 |

200 |

200 |

200 |

200 |

300 |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

Unit |

YQ32—400 |

YQ32—500 |

YQ32—630 |

YQ32—800 |

YQ32—1000 |

YQ32—1250 |

YQ32—1600 |

|

Nominal force |

KN |

4000 |

5000 |

6300 |

8000 |

10000 |

12500 |

16000 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

1250 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Max Stroke of Slider |

mm |

800 |

900 |

900 |

900 |

900 |

900 |

900 |

|

Effective table size |

mm |

1260×1160 |

1400×1400 |

1500×1500 |

1600×1600 |

1600×1600 |

1600×1600 |

1600×1600 |

|

Down speed |

mm/s |

100 |

150 |

150 |

180 |

180 |

180 |

190 |

|

Pressing speed |

mm/s |

5~11 |

10~18 |

9~18 |

9~18 |

10~18 |

6~15 |

6~14 |

|

Return speed |

mm/s |

100 |

180 |

200 |

180 |

220 |

200 |

220 |

|

Ejection cylinder force |

KN |

630 |

1000 |

1000 |

1000 |

1000 |

1000 |

1600 |

|

Stroke of ejection cylinder |

mm |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

Performance characteristics: high efficiency, precision, durability

High efficiency: through moderate acceleration and deceleration control, the working rhythm is several times higher than the traditional hydraulic press;

High precision: high parallel precision of slider and table, repeatable positioning accuracy of ±0.03mm;

Low noise: adopting internal gear oil pump, the noise is 10-15dB lower than the traditional plunger pump;

Long life: the frame and rollers are guided by high-precision sliding rails, with strong impact resistance and 30% longer maintenance cycle.

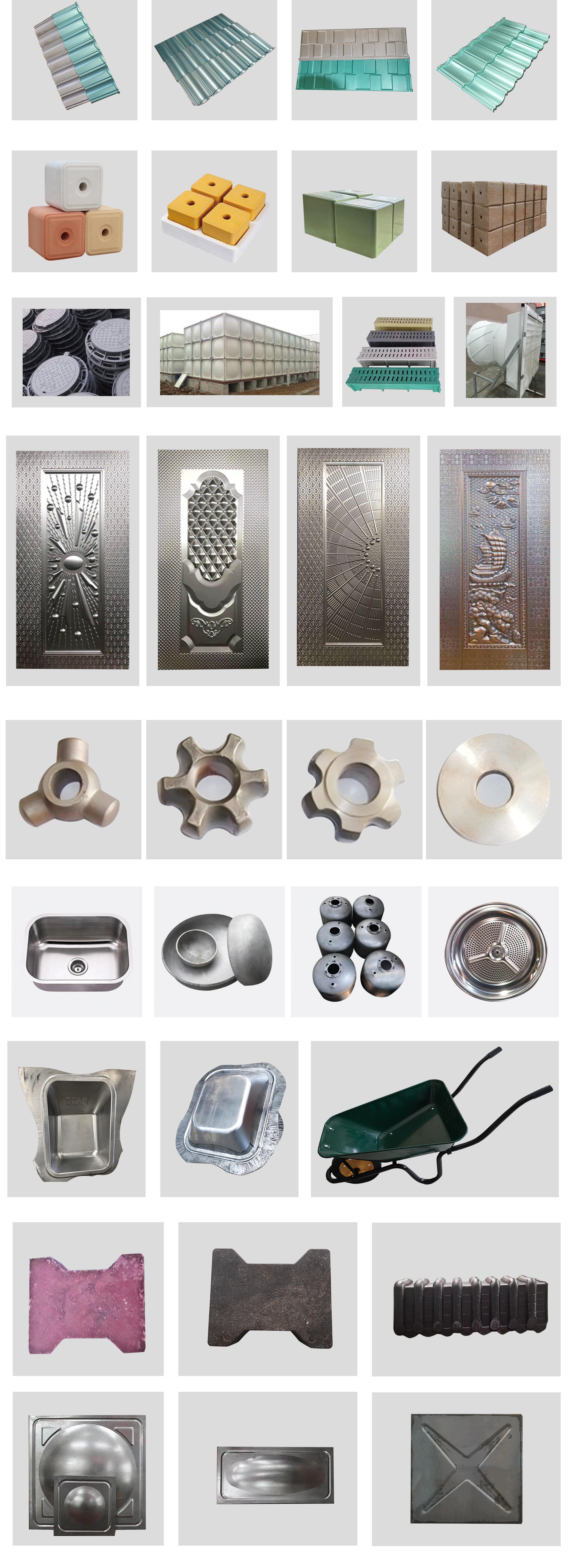

The 500-ton four-column hydraulic press is widely used in the following scenarios due to moderate pressure and high flexibility:

Metal forming: stamping (e.g. auto parts, appliance shells), stretching (stainless steel sinks, pots and pans), bending (metal brackets, structural parts).

Powder metallurgy: pressing iron-based and copper-based powder products (e.g. gears, bearings), matching mold heating function is required.

Rubber/plastic processing: rubber vulcanization, finishing of plastic profiles after extrusion (e.g. seals, cell phone cases).

Mold testing: small batch trial mold or debugging mold parameters (pressure, stroke).

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy