|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

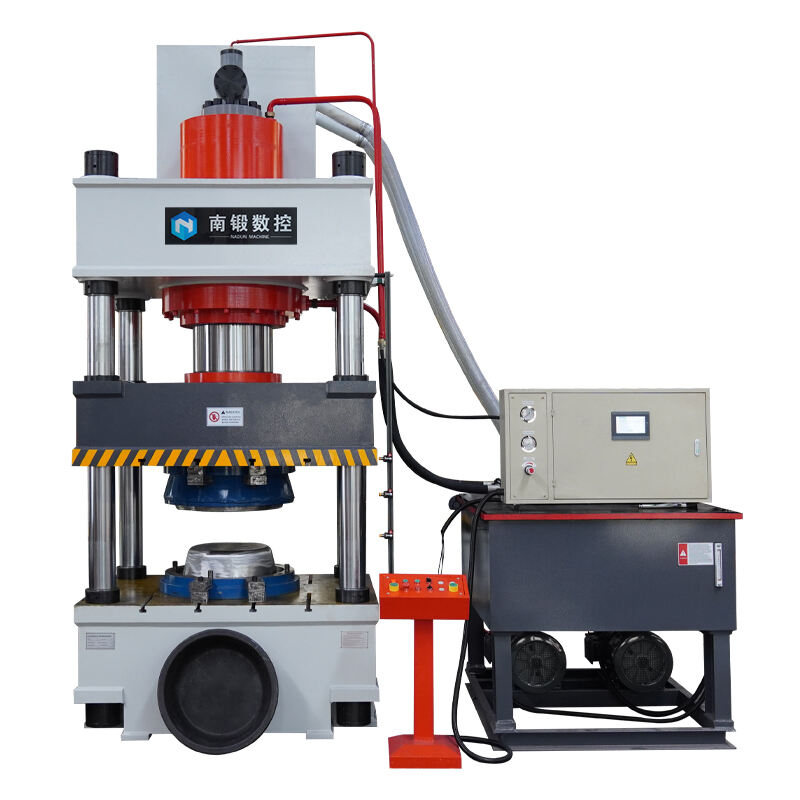

Model Number: |

YQ32-500T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

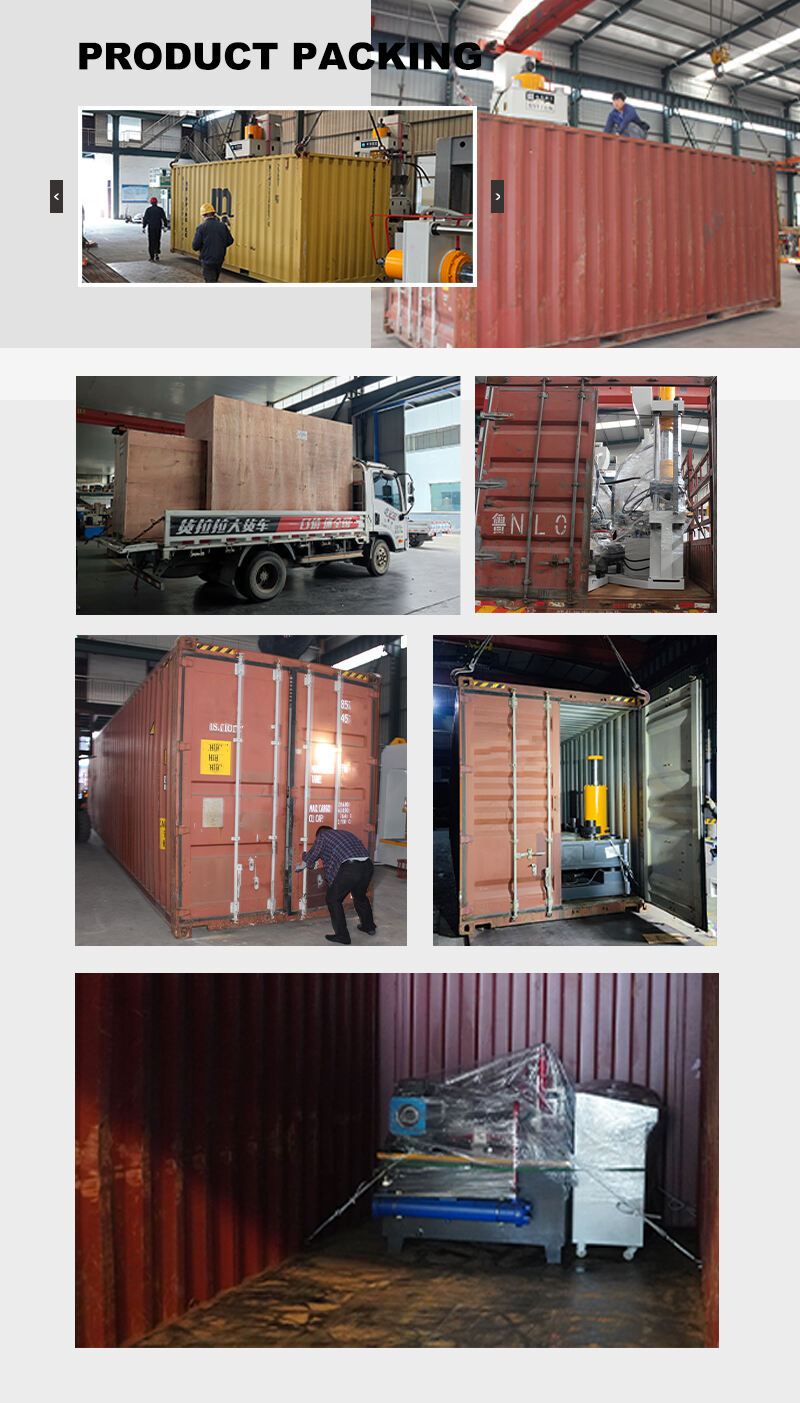

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

The 500-ton plastic basin hydraulic press usually adopts three-beam and four-column structure, with high-pressure stable output, large pressing area and multi-process linkage capability, which is suitable for the molding of medium and large-sized plastic products, such as plastic basins, trays, logistic containers and so on, and can satisfy the production demand of high-strength and complex structure plastic products.

Features & Benefits

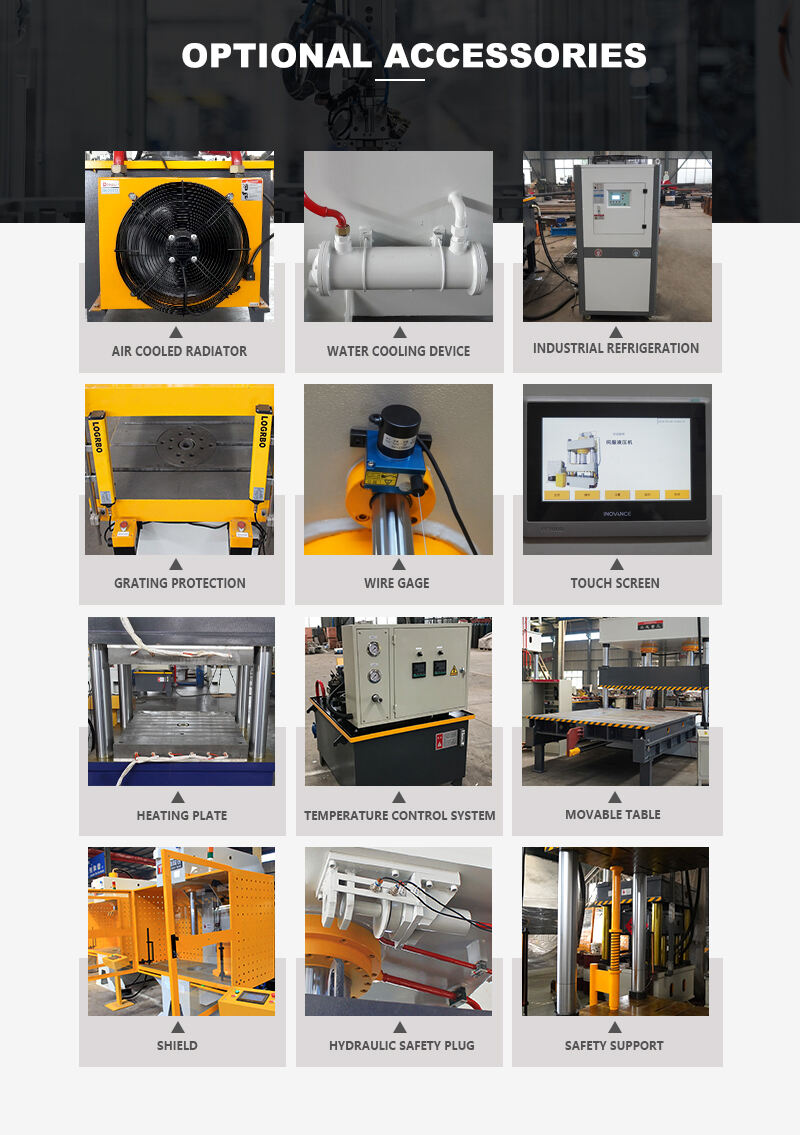

Independent power and electrical system

Adopting time relay or PLC touch screen control, supporting automatic and spot operation, realizing two kinds of molding process of fixed range and fixed pressure, and having the function of holding pressure delay with adjustable delay time.

Adjustable pressure and stroke

The working pressure can be adjusted by manual regulator, and the stroke range can be controlled by proximity switch, which can meet the process requirements of different plastic products.

High-precision guiding system

Equipped with square indenter and guide column as standard, the bottom plane of indenter is set with T-slot to ensure the working precision and versatility of the machine. The column is made of 45# steel with tempering treatment and hard chrome plated surface, which improves the wear resistance and anti-offset load capacity.

Safety and humanized design

It is equipped with centralized control panel, arranging operation buttons and selection switches; light curtain protection is equipped as standard to ensure the safety of operators; the position of the hydraulic station can be left or right, which can be flexibly configured according to customers' needs.

Application Scenarios

Molding of large plastic tubs and containers

Pressing medium and large plastic tubs, stackable baskets, cold chain box liner, etc., suitable for food transportation, pharmaceutical storage, electronic logistics and other industries. Compared with injection molding equipment, hydraulic molding is more suitable for the manufacture of plastic products with large wall thickness, complex structure and high load-bearing capacity.

Composite Molding

Integrated vacuum-assisted and hot pressing system to improve material density and surface quality, suitable for FRP, SMC/BMC molded parts production, such as traffic facilities shield, electrical control box shell.

Rubber and powder metallurgy molding

Equipped with vacuum exhaust and in-mold heating system, it can press rubber tracks, large gaskets, etc.; it supports metal powder and ceramic powder molding, such as synchronous wheels, gears, cutting tool blanks and other high-strength structural parts preforms.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy