|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

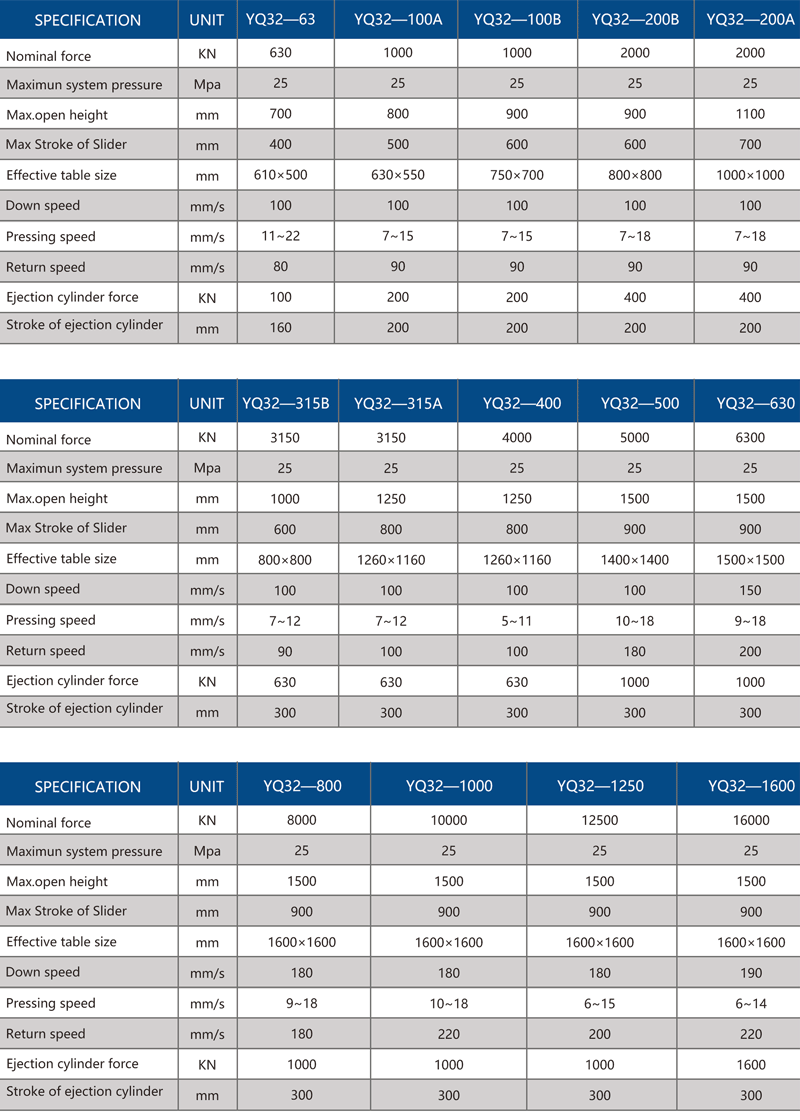

Model Number: |

YQ32-315T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

The 315-ton bulletproof insert plate hydraulic press is a critical piece of equipment for pressing bulletproof insert plates (such as ceramic, polyethylene, and other materials). Typically employing a four-column structure, it possesses high-temperature, high-pressure hot pressing capabilities to ensure the density, hardness, and structural integrity of the bulletproof insert plates, thereby meeting ballistic performance requirements.

Structure Type: Primarily four-column hydraulic presses, featuring excellent stability and high fatigue strength to ensure reliable operation under rated loads.

Power and Control: Equipped with independent power units and electrical control systems, typically employing PLC-controlled touchscreens and button interfaces for dual-mode operation. Offers manual and semi-automatic modes with adjustable working pressure and speed for user-friendly operation.

Functional Configuration: Features pressure display, temperature display/alarm, cycle counter, and pressure hold time setting devices. Offers stable performance, reliable pressure retention, precise timing, and high automation.

Material Pressing: Primarily used for specialized presses in bulletproof composite materials (such as ceramics, polyethylene, etc.), as well as cold pressing of metals and forming large thin-shell plates like fiber composites.

Product Manufacturing: During the production of ballistic insert plates, hydraulic presses utilize hot-press forming to transform raw materials into final products with exceptional ballistic performance. This process directly determines the density, hardness, and structural integrity of the ballistic plates, serving as the critical factor in their ability to effectively resist bullets.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy