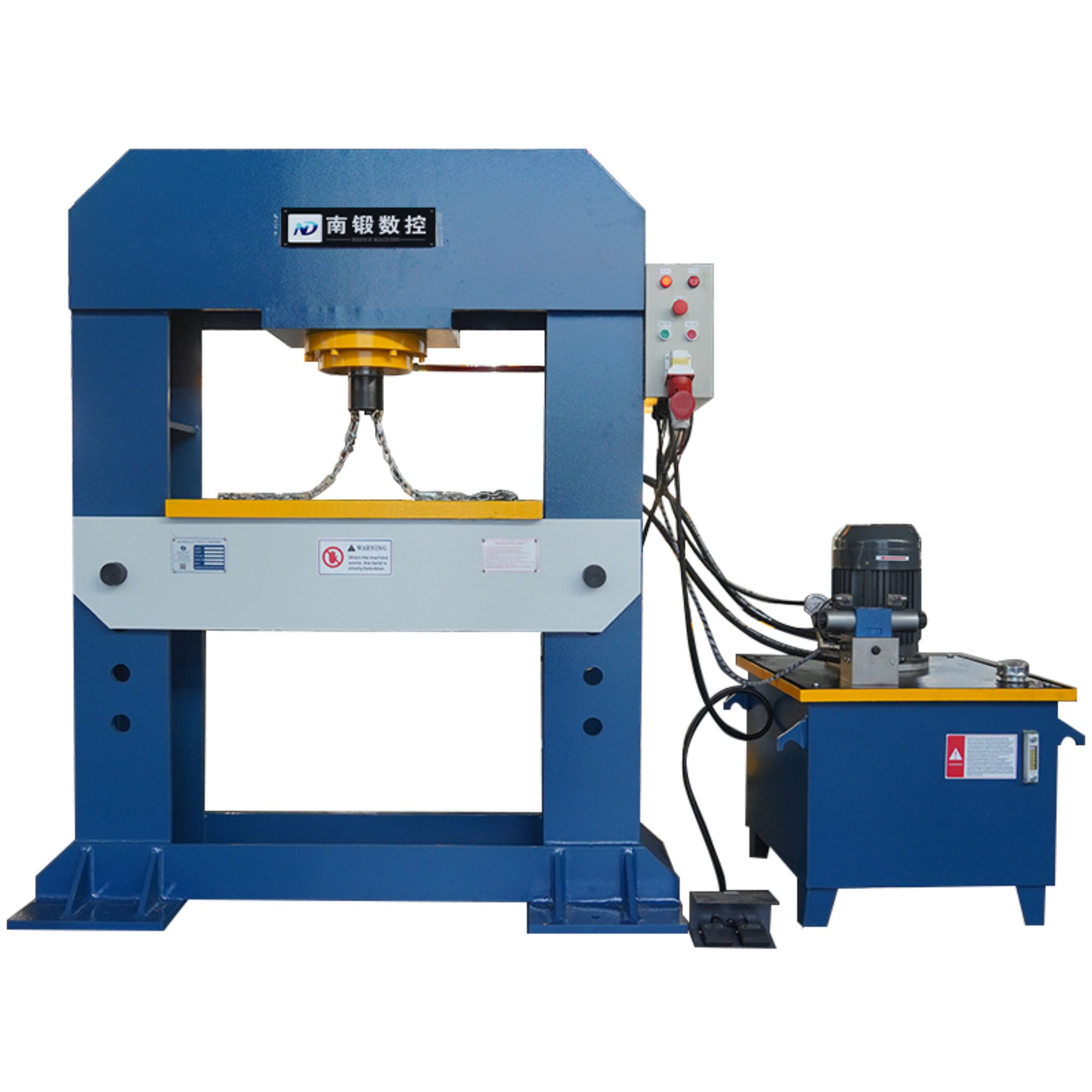

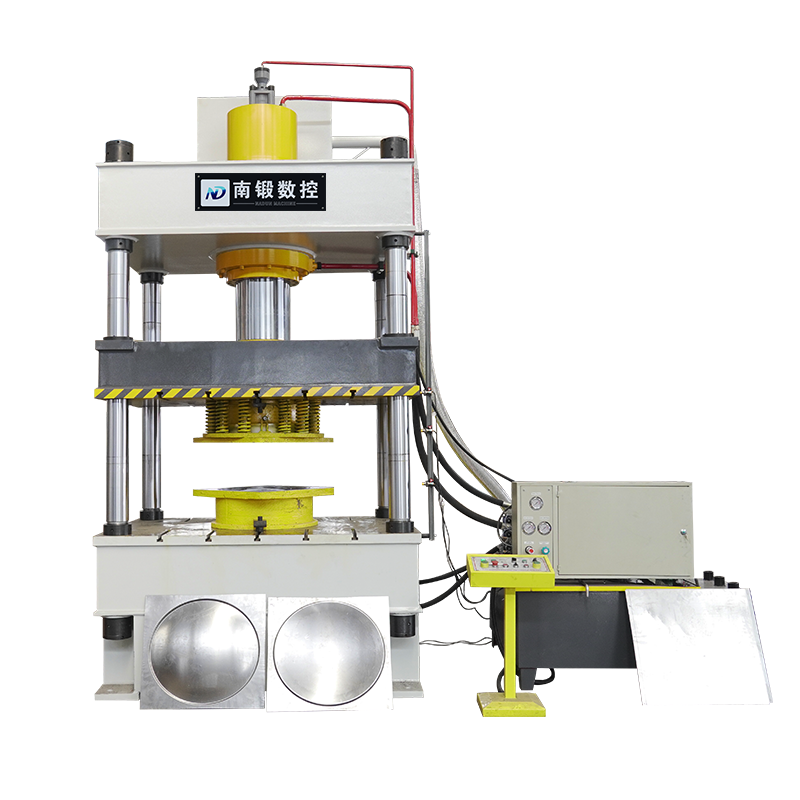

شركة نادون للماكينات المحدودة

ماكينة مكبس السحب العميق

نستخدم مطبخ هيدروليكي للجذب العميق لإنتاج منتجات مثل الكوب، كوب السجائر، الوعاء، الكنة وغيرها. هذه الآلة تُعتبر واحدة من أكثر الآلات فائدة لأنها قادرة على تشكيل المعادن إلى أشكال مختلفة. بشكل عام، تكون ذات شكل دائري أو مربع. في هذا الدليل، سنتحدث عن كل ما يجب معرفته حول آلات الضغط بالسحب العميق؛ ما هي، وماذا تفعل، وكيفية العثور على الأفضل بالنسبة لك.

المادة: يتم تصميم آلات مختلفة للعمل مع أنواع مختلفة من المواد. بعض الآلات يمكنها معالجة مادة معينة فقط، مثل الألمنيوم أو الصلب. لذا إذا كنت تعرف بالفعل المادة التي تريد استخدامها، تأكد من أن الآلة التي اخترتها قادرة على قص تلك المادة. إنها مثل استخدام أداة لأداء مهمة، واستخدام الأداة المناسبة هو كل ما نريده!

كيفية اختيار ماكينة السحب العميق المناسبة لاحتياجاتك؟

السرعة: مدى سرعة قدرة الآلة على إنتاج العناصر هو أيضًا عامل مهم. تريد آلة يمكنها إنتاج المنتجات بسرعة، ولكنك تريد أيضًا أن تكون قادرة على الحفاظ على جودة جيدة. من ناحية أخرى، إذا كانت الآلة بطيئة، قد يكون من الصعب الحفاظ على أهداف الإنتاج. لذلك، التوازن بين السرعة والجودة هو المفتاح لتحقيق نقطة التوازن المثالية.

لإنشاء منتجات دقيقة: أحد أعظم المزايا هو أن هذه الآلات قادرة على تصنيع منتجات دقيقة ودقيقة للغاية. فهي تطبق ضغطًا كبيرًا على المادة، مما يضمن أن المادة النهائية تكون متسقة وتُبنى ضمن التسامح المطلوب. كما يعني ذلك أن كل قطعة يتم إنتاجها ستكون متطابقة في الحجم والشكل، وهو أمر مهم لمتابعة جودة الإخراج.

-

المزايا باستخدام ماكينة السحب العميق في خط إنتاجك.

اقتصادية: يمكن للمصنعين توفير المال باستخدام آلات الضغط لسحب العمق. فهي تمكن الشركات من تصنيع السلع بتكاليف أقل مع الحفاظ على الجودة. تأتي مثل هذه التوفيرات من تقليل متطلبات العمالة وقدرة الآلات على إنتاج الأشياء بشكل أسرع. لذلك عندما يوفر المصنعون المال، يمكنهم تخصيص الموارد في أماكن أخرى من أعمالهم.

-

أنواع القوالب الأكثر شيوعًا المستخدمة في ماكينات السحب العميق.

التشحيم غير الكافي: نقص التشحيم المناسب يمكن أن يؤدي إلى مشاكل في الجهاز. يمكن أن يتسبب التشحيم غير الفعال في احتكاك بين أجزاء الجهاز، مما يؤدي إلى تعطله. الوقاية: حافظ على تشحيم الجهاز بشكل جيد لتجنب هذه التجربة. مع التشحيم المتكرر، سيساعد ذلك على عمل المعدات بسلاسة.

-

نصائح لحل المشكلات الشائعة المتعلقة بماكينات السحب العميق.

انسداد المواد: بشكل دوري، يمكن أن تصبح المواد التي يتم معالجتها عالقة داخل الجهاز. قد يحدث ذلك إذا كانت المواد ليست بالسماكة الصحيحة، أو إذا كانت القطع عالقة داخل الجهاز. للوقاية من هذه المشكلة، تأكد دائمًا أن المواد التي تعمل عليها تكون بالحجم المناسب، وأن الجهاز خالي من الأوساخ والشحوم.

Why choose نادون ماكينة مكبس السحب العميق?

-

خبرة الشركة وانتشارها العالمي:

مع أكثر من 17 عامًا من الخبرة، برزت شركة نادون للآلات كمُصنّع ورائدة في مجال التصدير والتصنيع في معالجة المعادن. نحن نركز على مكابس الهيدروليك، ومكابس الثقب، وآلات القص، وآلات الثني، والماكينات الخراطة العمودية التي تلبي احتياجات مختلف الصناعات مثل الفضاء الجوي، وتصنيع السيارات، والهندسة الميكانيكية، والبناء، والهندسة المعدنية. وتُوزَّع ماكيناتنا ل presses السحب العميق في أكثر من 150 دولة حول العالم، وتحدد معايير جديدة لآلات التصنيع.

-

جودة وأداء متميز:

تُعرف شركة نادون ماشينري بمكابس السحب العميق عالية الجودة التي تتميز بأداءٍ ممتاز ومتانةٍ طويلة الأمد في خدمتها. وتضم شركة نادون ماشينري فريقًا من الباحثين والمطورين يتكوّن من أكثر من عشرة أشخاص، لكلٍّ منهم متوسط خبرة تزيد على ١٠ سنوات في مجال البحث والتطوير. وهم يواصلون باستمرار الابتكار وتطوير منتجاتهم لتلبية احتياجات السوق.

-

مجموعة متنوعة من المنتجات

للاستجابة للطلب المتزايد في السوق على منتجات التبريد، تقدّم آلات السحب العميق التابعة لشركتي دراغون آند تايغر (التنين والوحش) وتمبل أوف هيفن (معبد السماء) مجموعةً واسعةً من المنتجات التي يمكن ضبطها لتناسب مختلف أنواع المستخدمين والمستهلكين. ويستند عزم الشركة على أن تصبح شركةً رائدةً في قطاع الصحة إلى تطوير منتجات علامة تجارية تركز على الصحة والعافية، وكذلك على تحسين تجربة المستخدم.

-

جودة المنتج الموثوقة

توفر الشركة خدمات تركيب وتشغيل أكثر من ٤٠٠ عميل سنويًّا. وتُصنِّع ما بين ٥٠٠ و٦٠٠ مجموعة من المنتجات المختلفة كل عام. وقد حصلت هذه المنتجات على شهادات معايير الأيزو والسي إي و إس جي إس. ونحن حائزون على عددٍ كبيرٍ من الشهادات التقديرية الخاصة ببراءات اختراع الابتكارات المنتَجة، والتي تدلّ على التزامنا بتطوير آلات الضغط للسحب العميق.

فئات المنتجات ذات الصلة

هل تبحث عن شيءٍ ما ولا تجده؟

اتصل بمستشارينا للحصول على مزيد من المنتجات المتاحة.

اطلب عرض أسعار الآن

إلمس

حقوق النشر © شركة نادون للمعدات الميكانيكية المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN