Nadun’s CNC metal benders angle machine calibration and maintenance apparatus Machine item Description A machine for making angle adjustment of the CNC bender for metal for the machine operation 2. With regular calibration, the machine is running at peak performance and thereby providing precision bending to your metal parts. Maintenance is also critical to maintain the equipment, minimising the risk of errors in angle measurements.

Advantages

Properties of material and thickness of metal are important factors to be taken into account during the CNC metal bending process. The flexibility and strength of various types of metals can influence the bending operation. The material thickness also plays a part in the degree of angle accuracy, thicker materials will take more force to correctly bend.

Benefits

Cutting tools's option and fix are very important factors to angle accuracy in CNC metal bending machine. Able to make accurate bends over and over, they allow you to do a good job when using the right tool and setting it up properly. There’s also a lower likelihood for material distortion or any kind of damage on the workpiece if you use the right set of tools.

Features

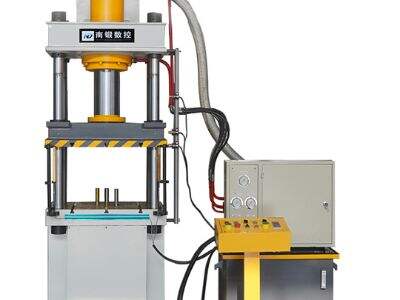

Operator's 100 ton hydraulic press machine experience and skill is all that's needed to get angle precision in Nadun CNC metal bending machines. Operators with decades of experience can run the machines on-the-fly and tune any bending problems as they occur. Equally importantly, skilled due operators can operate in a highly productive manner, and therefore provide significant savings in terms of time and resources for the production output.

The click precision of the CNC metal bending machine is closely related to the software and programming ability. The programming software for bending must be precise and reliable so that bended parts are made correctly. The capabilities of the software are also critical as they can determine what type of bends can be made, enabling a greater variety of metal parts to be produced.

Summary

In summary, there are many factors that affect the angle precision of Nadun's CNC metal bending machine. There are many variables that go into consistent and accurate bending, such as machine calibration and maintenance, material type and thickness, which tooling was selected and set, level of operator skill and experience, plus programming and software capability. If Nadun takes these considerations and makes sure that they are maximized, he should be able to continue cranking out quality metal components, and implementing them in range of industries.

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN