|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

Model Number: |

YQ32-315T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

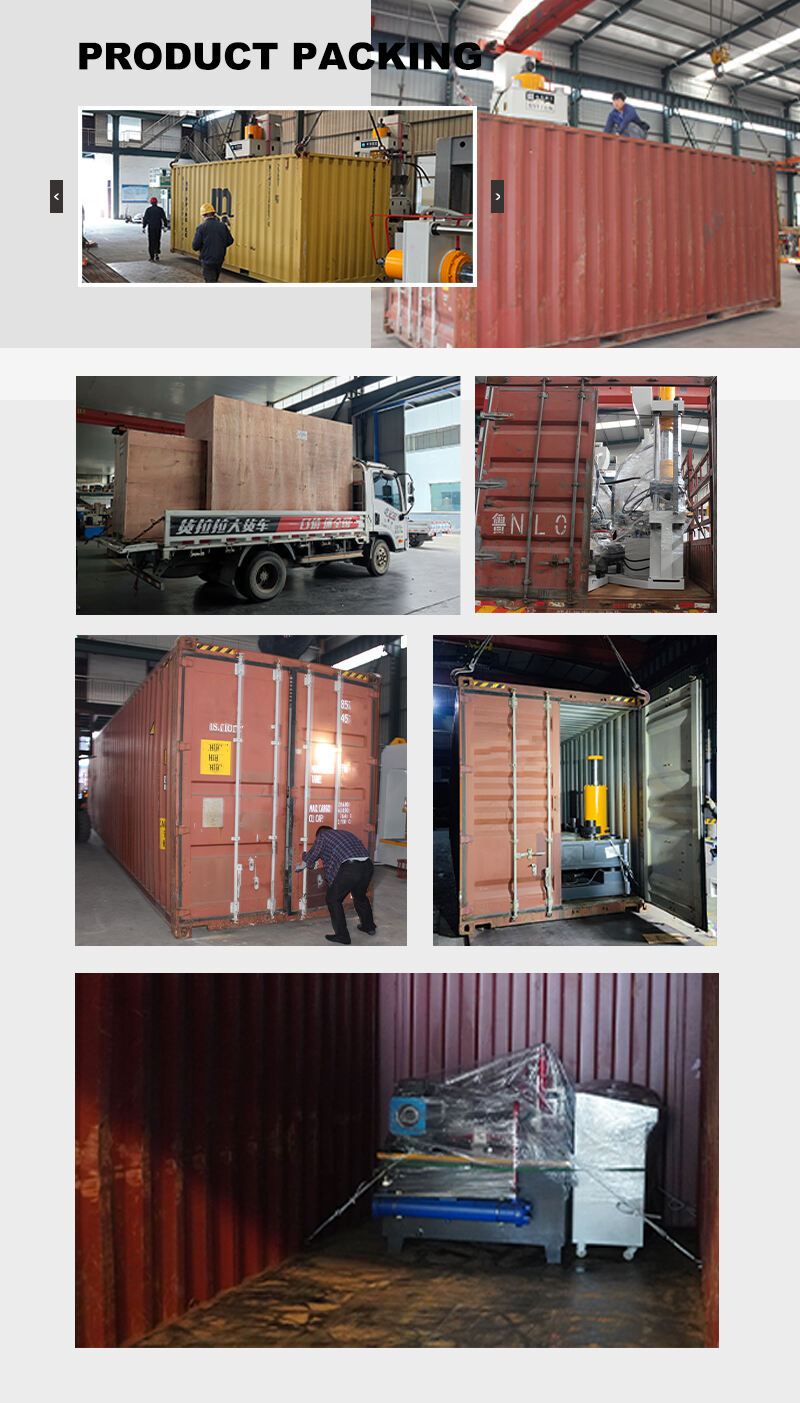

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

Composite material crash cushion plate hydraulic press is specially designed for composite material crash cushion plate molding process, its core function is to press the fiber reinforced resin-based composite material (such as glass fiber/epoxy resin/aramid fiber/vinyl ester resin, etc.) into the mold with specific shape, density and mechanical properties. Its core function is to press the fiber reinforced resin matrix composites (e.g. glass fiber/epoxy resin, aramid fiber/vinyl ester resin, etc.) in the mold to form the crash cushion plate with specific shape, density and mechanical properties.

High precision pressure control

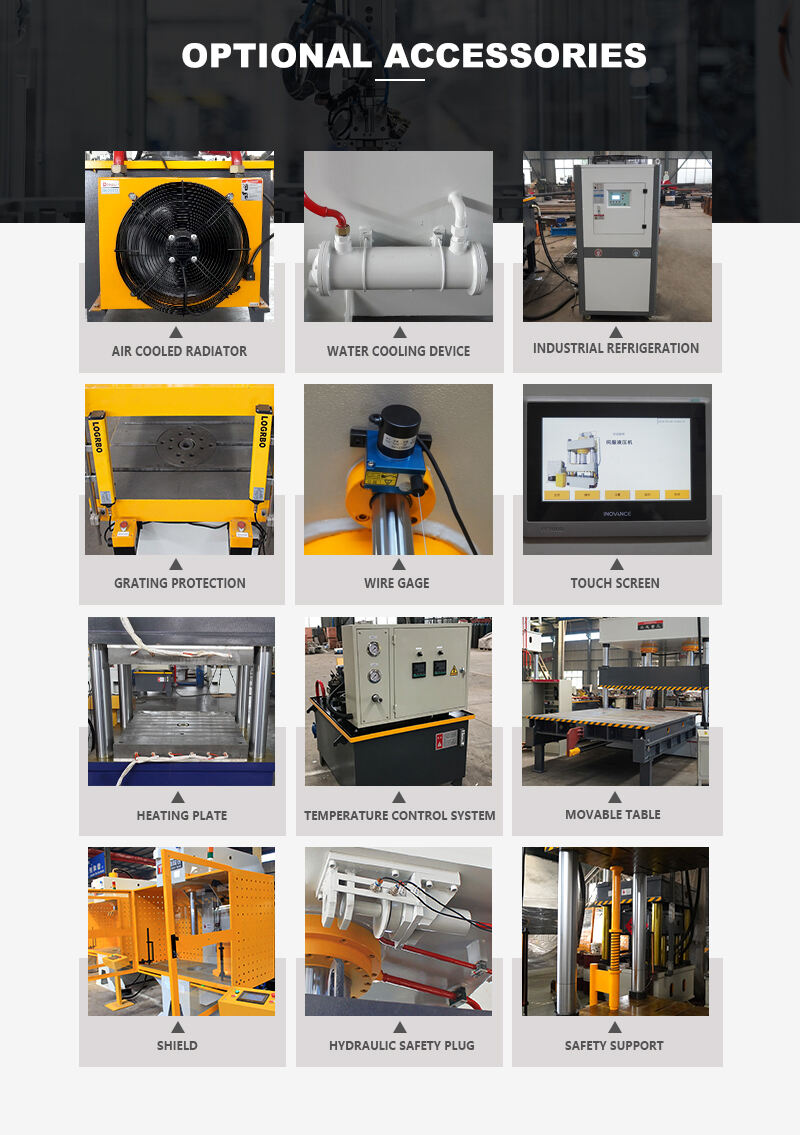

Anti-collision type pads need to have impact resistance and fatigue resistance, the hydraulic press needs to realize closed-loop pressure control through servo motor + PLC system to ensure that the pressure fluctuation in the pressing process is ≤±1%, to avoid the products from uneven pressure resulting in density difference, which will affect the anti-collision performance.

Multi-stage speed process support

Anti-collision pad molding usually needs to go through multi-stage processes such as fast mold closing, slow exhaust, high pressure holding, fast return, and so on.

Temperature uniformity control

If thermosetting materials (e.g. SMC, BMC) are used, the hydraulic press needs to be integrated with a mold temperature control system to achieve mold temperature uniformity of ±2℃ or less by means of heat-conducting oil or electric heating, so as to avoid inconsistencies in shrinkage rate of the products due to the temperature difference, which affects the dimensional accuracy and structural strength of the crash cushion plate.

Typical Application Scenarios

Transportation field

Automobile crash beams: carbon fiber composites or FRP are used, molded by hydraulic press to realize the combination of light weight and high strength.

Railway transportation pads: such as high-speed rail track vibration damping pads, high damping rubber composite materials need to be pressed by hydraulic presses to ensure that the vibration attenuation rate is ≥80%, and the hydraulic presses need to be equipped with a core extraction system to realize the molding of complex structures.

Industrial Protection

Mechanical equipment guards: SMC sheet molding, hydraulic presses need to support large table and high pressure to ensure that the product surface finish and dimensional accuracy.

Explosion-proof wall mat: aramid fiber reinforced composite materials need to be pressed through the hydraulic press to achieve impact energy ≥ 50kJ/m², the hydraulic press needs to be equipped with an overload protection device.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

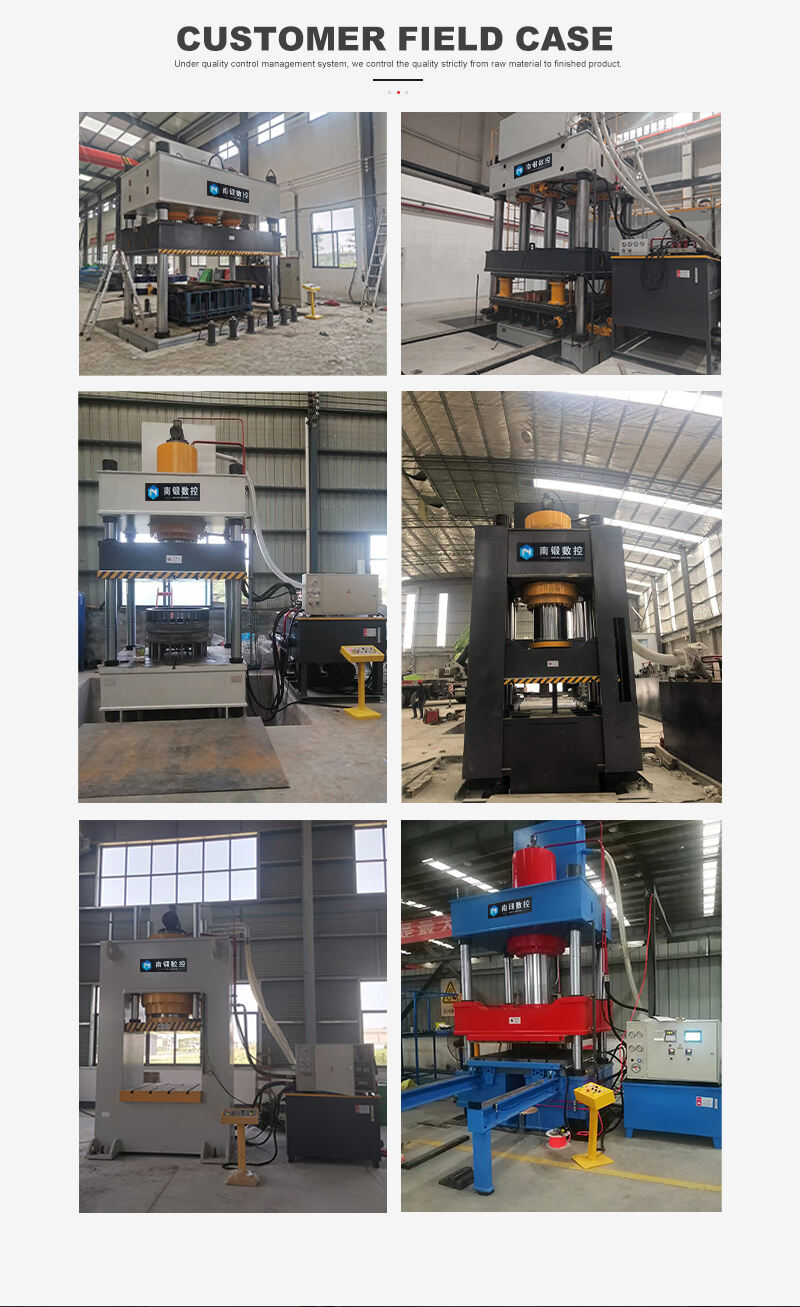

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy