Nadun Machinery Manufacture Co., Ltd.

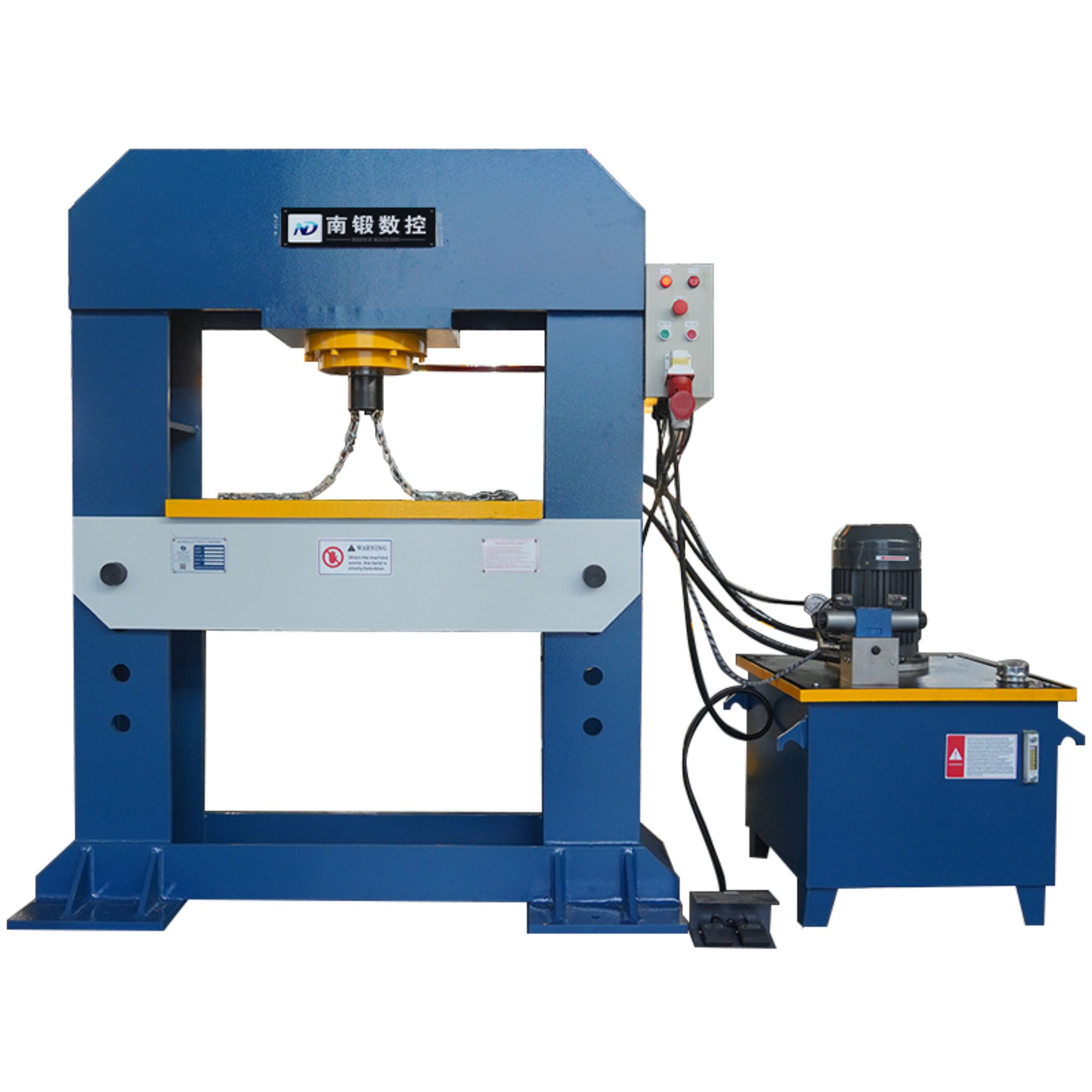

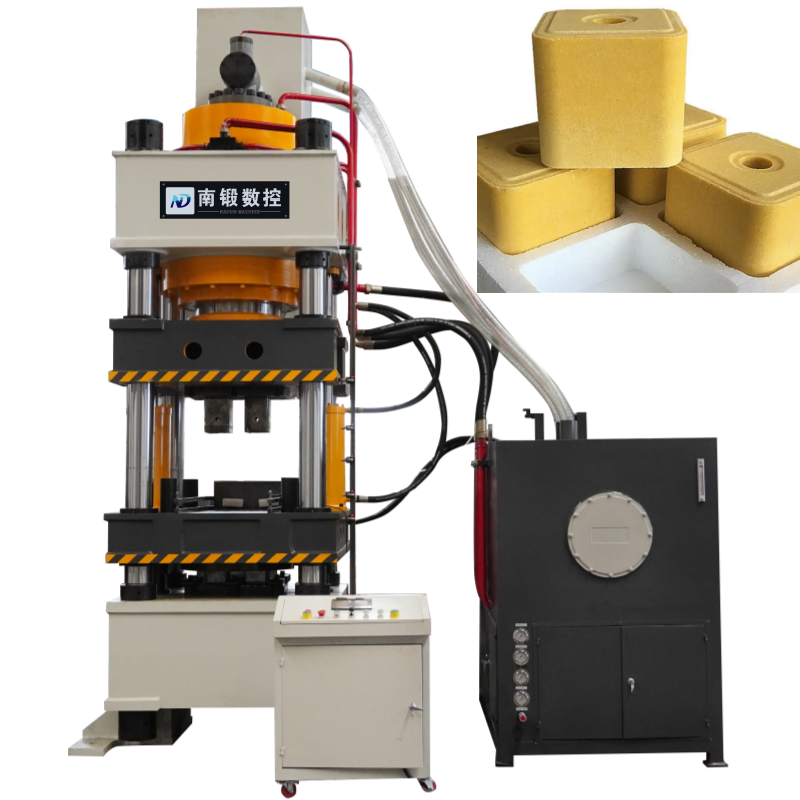

Presse hydraulique pour roulements

Aujourd'hui, nous allons continuer à étudier la presse hydraulique pour roulements. Nadun PRESSE HYDRAULIQUE a une grande importance, car cela aide les usines à produire divers produits. Elle joue un grand rôle dans la fabrication, et nous allons décrypter comment elle fonctionne et pourquoi c'est d'une telle importance pour les travailleurs et les entreprises.

Comment les presses hydrauliques à roulements améliorent la fabrication

Et lorsque les usines commencent à produire une variété de choses différentes, les machines avec moteur aident également. L'une des machines importantes parmi elles est le presse hydraulique à roulements. Nadun Machine de perçage hydraulique peut effectuer une large gamme de tâches, telles que la mise en forme du métal ou l'extraction de jus à partir de matières premières. Il est si robuste et, en appliquant un peu de pression, il peut gérer beaucoup. Ces capacités augmentent alors considérablement la vitesse à laquelle les usines peuvent fonctionner et produire des produits hautement détaillés et complexes.

-

Les avantages de l'utilisation d'une presse hydraulique à roulements

L'utilisation d'une presse hydraulique aidera certainement les petites usines à économiser du temps et de l'argent. Avant l'invention de ces machines incroyables, les travailleurs devaient utiliser d'autres outils qui n'étaient pas toujours aussi puissants ou qui prenaient simplement trop de temps. Parfois, les vieux outils entraînaient de nouvelles erreurs qui ne faisaient qu'augmenter le gaspillage de temps. De plus, la presse apporte également une sécurité supplémentaire dans le processus de fabrication pour les employés. C'est beaucoup plus facile et utile pour les employés de faire fonctionner une machine plutôt que d'avoir tout opéré séparément. Nadun presse hydraulique automatique est également capable de soulever de nombreuses livres si elle était plus lourde, un homme ou une femme seule ne pourrait pas la soulever. C'est une autre raison pour laquelle une presse hydraulique est un équipement si utile dans les usines.

-

La technologie derrière les presses hydrauliques à roulements

Mais comment ce dispositif fonctionne-t-il, vous vous demandez peut-être. Il fonctionne par un processus appelé puissance hydraulique. Cet impact est causé par un liquide spécialisé, généralement de l'huile, en utilisant la pression. Si un utilisateur souhaite utiliser la presse, il ou elle allumera la machine et la configurera en fonction de la quantité de pression nécessaire. Ils placeront ensuite le matériau qu'ils souhaitent former sous la presse et appuieront sur un bouton. Le matériau est alors comprimé entre deux plaques robustes par la presse hydraulique à banc . Comme la presse atteint une pression si élevée lorsqu'elle moule ou forme une autre forme désirée du matériau. Cela m'étonne que quelque chose comme ça, simplement avec de la pression, puisse transformer un matériau à de tels extrêmes.

-

La polyvalence des presses hydrauliques à roulements

Le meilleur des presses hydrauliques avec roulements est leur flexibilité. Machine à percer mécanique effectuer de nombreux services. Par exemple, ils sont utilisés pour presser, serrer, percer. Très utile pour le soudage ou la peinture également. En résumé, ces presses hydrauliques à roulements existent en différents types qui peuvent être utilisés pour une variété de tâches et cela permettra aux usines d'utiliser une seule machine pendant des années. Économie importante ici puisqu'il n'est pas nécessaire d'avoir plusieurs machines pour des travaux différents. Au lieu de cela, ils n'ont besoin que d'une machine capable d'effectuer des dizaines de tâches pour bénéficier d'une efficacité en grande quantité.

Why choose Nadun Presse hydraulique pour roulements?

-

Une variété de produits

Dans le domaine des produits de refroidissement, les marques Dragon et Tigre ainsi que la marque Temple du Ciel souhaitent répondre à la forte demande du marché, avec une variété de produits adaptés à différents consommateurs et scénarios d'utilisation. Axée sur la construction de la marque comme pilier principal, mettant l'accent principalement sur les produits liés à la santé et sur l'expérience utilisateur comme base, l'entreprise palier presse hydraulique vise à s'imposer comme une entreprise de classe mondiale dans le secteur de la santé.

-

Expertise de l'entreprise et présence mondiale :

Nadun Machinery est un fabricant et exportateur de premier plan de machines pour le traitement des métaux, avec plus de 17 ans d’expérience. Nous nous spécialisons dans les presses hydrauliques, les presses à poinçonner, les machines de cisaillement, les machines de pliage et les tours verticaux. Nous desservons divers secteurs tels que l’aérospatiale, la fabrication automobile, la construction, le génie mécanique et la métallurgie. Nos produits, notamment la presse hydraulique Bearing, sont présents dans plus de 150 pays à travers le monde, établissant de nouvelles normes en matière de machines de fabrication.

-

Qualité de produit fiable

L’entreprise assure l’installation et la mise en service de plus de 400 presses hydrauliques Bearing chaque année. Elle fabrique annuellement entre 500 et 600 unités de produits variés. Ces produits sont certifiés ISO, CE et SGS. Notre engagement envers l’excellence se reflète dans de nombreux brevets d’innovation produit ainsi que dans les diplômes honorifiques que nous avons reçus.

-

Qualité et Performance Exceptionnelles :

Les produits Nadun Machinery sont reconnus pour leur qualité supérieure, leurs performances excellentes et leur longue durée de vie. Nadun Machinery dispose d'une équipe de recherche et développement expérimentée composée de plus de dix employés, chacun possédant en moyenne plus de 10 ans d'expérience en recherche et développement. Notre équipe ne cesse de s'améliorer et d'innover pour répondre aux évolutions des demandes en presses hydrauliques et roulements.

Catégories de produits associés

- presse de 60 tonnes

- presse hydraulique de 100 tonnes

- machine presse hydraulique de 100 tonnes

- machine presse de 100 tonnes

- presse hydraulique de 150 tonnes

- presse de 150 tonnes

- presse hydraulique de 200 tonnes

- presse de 200 tonnes

- presse hydraulique de 300 tonnes

- Pliage horizontal

- Plus forte presse hydraulique

- Élagage hydraulique de tôles

Vous ne trouvez pas ce que vous cherchez ?

Contactez nos consultants pour plus de produits disponibles.

Demandez un devis maintenant

Contactez-nous

Droits d'auteur © Nadun Machinery Manufacture Co., Ltd. Tous droits réservés - Politique de confidentialité

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN