Nadun Machinery Manufacture Co., Ltd.

compression molding press

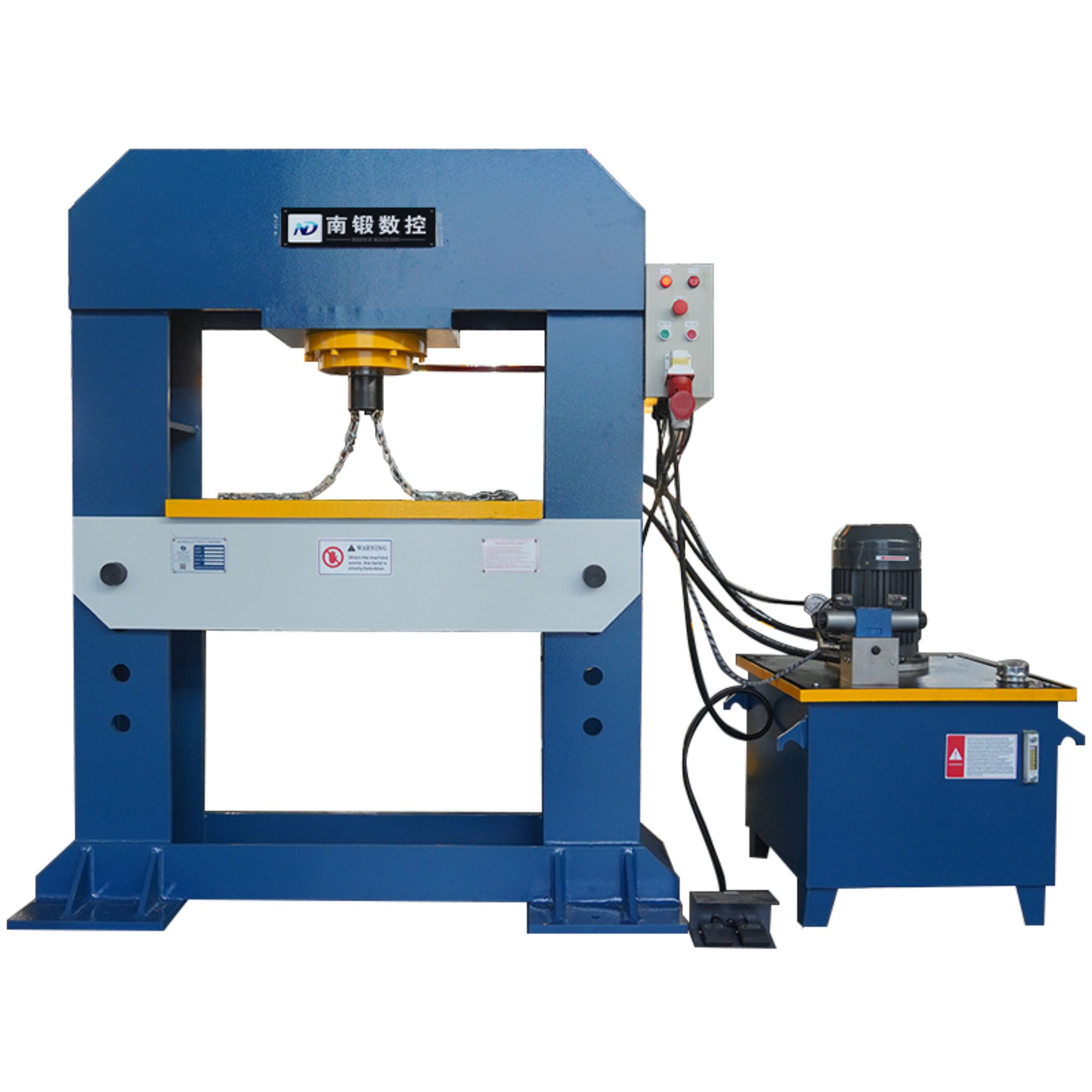

Nadun est une entreprise de fabrication de machines qui produit des machines pour tous types d'entreprises. La presse hydraulique de 60 tonnes , par exemple, est l'une des pièces les plus critiques des machines qu'ils fabriquent. C'est également une machine très utile - elle forme le matériau afin qu'il puisse être moulé en produit conforme à nos désirs. L'un des plus grands avantages de l'utilisation d'une presse à moulage par compression réside dans le fait qu'elle fournit le même moule et la même forme parfaits à chaque fois, ce qui est un facteur important dans la fabrication.

Avant d'utiliser la presse à moulage par compression, il faut d'abord charger le matériau dans la machine. Ces matériaux peuvent être variés, comme du caoutchouc ou du plastique. Une fois que le matériau entre, la machine commence à fonctionner. Elle comprime le matériau de tous les côtés sous haute pression jusqu'à ce que le matériau prenne la forme désirée. La force utilisée est très élevée et appliquée uniformément dans toutes les directions. Autrement dit, la forme est homogène à travers tout le matériau. Cela rend le produit final très beau, sans erreur ni défaut, ce dont une entreprise a besoin.

Procédé de production efficace avec la technologie de presse à moulage par compression

De plus, utiliser la presse de 60 tonnes est également un excellent moyen d'accélérer la production. Envoyer un article à une usine pour être produit en série ou en lots n'est plus un défi — les usines recherchent toujours le moyen le plus simple et rapide de fabriquer des articles pour satisfaire les clients. Une grande partie de ce processus repose sur la presse à moulage par compression, car elles peuvent accélérer considérablement tout le processus.

La mise en forme se produit automatiquement lorsque nous utilisons la presse à moulage par compression. Une fois que vous chargez le matériau dans la machine, elle s'occupe du reste ! Donc, cette machine comprime quelque chose jusqu'à ce qu'en quelques instants, cela sorte sous la forme souhaitée. C'est pourquoi cette automatisation est extrêmement utile car elle aide à réduire le temps de production, ce qui rend le processus de production plus rapide et efficace, permettant ainsi de produire beaucoup en moins de temps.

-

Polyvalence et précision avec les machines de presse à moulage par compression

La presse à moulage par compression est une machine extrêmement polyvalente, qui peut être utilisée pour une large gamme de tâches dans divers secteurs industriels. Elle est capable de façonner une grande variété de matériaux, tels que le caoutchouc, le plastique et même les matériaux composites. De plus, elle offre une grande flexibilité, car selon les besoins de l'industrie, la machine est capable de créer des formes dans différentes tailles.

-

Réduction des déchets de matériaux grâce à la technologie de presse à moulage par compression

Lorsque la machine reçoit une pression appliquée, le matériau est réparti uniformément et réduit les déchets. Cela aide également à éviter toute erreur ou déformation du produit. Le fait de le façonner moins signifie que moins de matériel est gaspillé si le produit final est de qualité et précis. Non seulement l'économie de matériaux est un bon choix financier pour l'entreprise, mais cela contribue également à un environnement plus propre et plus sain pour tous.

-

Garantir des produits finis de haute qualité avec une presse à moulage par compression

Comme discuté précédemment, la presse à moulage par compression est une machine extrêmement précise et polyvalente. Elle aide les entreprises à formuler leur produit selon la forme et la consistance idéales. Avec cette machine, les organisations peuvent s'assurer que leurs produits sont de haute qualité et qu'ils ont toujours la même apparence à chaque production. La machine permet également à l'entreprise d'économiser de l'argent en réduisant la quantité de matériaux gaspillés lors de la production des produits finaux.

Why choose Nadun compression molding press?

-

Une variété de produits

Dans le domaine des solutions de refroidissement, les marques Dragon et Tiger ainsi que la marque Temple du Ciel répondent aux diverses demandes du marché grâce à une gamme de produits capables de s’adapter à différents types de clients et de scénarios d’utilisation. La construction de la marque constitue l’objectif prioritaire, les produits pour la santé étant principalement fabriqués à l’aide de presses à moulage par compression, et l’expérience client étant au cœur de notre démarche. L’entreprise s’est fixé pour objectif de devenir une entreprise de premier plan dans le secteur de la santé.

-

Qualité de produit fiable

Notre entreprise produit annuellement entre 500 et 600 unités (ensembles) de divers produits et fournit chaque année des services d’installation et de mise en service à plus de 400 clients. Nos produits sont certifiés ISO, CE, SGS, entre autres. Notre engagement en faveur de l’excellence se reflète notamment dans les nombreux brevets détenus dans le domaine de l’innovation liée à nos presses à moulage par compression, ainsi que dans les distinctions et certifications honorifiques que nous avons reçues.

-

Qualité et Performance Exceptionnelles :

Les produits Nadun Machinery sont réputés pour leur haute qualité, leurs excellentes performances et leur longévité. L'équipe de recherche et de conception compte plus de 10 personnes, possédant chacune plus de 10 ans d'expérience dans le domaine de la recherche et du développement. Elle utilise des presses à moulage par compression afin d’innover et d’améliorer continuellement nos produits, pour répondre aux besoins en constante évolution du marché.

-

Expertise de l'entreprise et présence mondiale :

Fort de plus de 17 ans d’expérience, Nadun Machinery, fabricant et exportateur renommé de presses à moulage par compression, intervient dans le traitement des métaux. Nous nous spécialisons dans les presses à emboutir, les presses hydrauliques, les machines de cisaillement et de pliage, ainsi que les tours verticaux, destinés à divers secteurs tels que la construction automobile, l’aérospatiale, le génie mécanique, le bâtiment et la métallurgie. Nos produits sont commercialisés dans plus de 150 pays à travers le monde, établissant de nouvelles normes dans le domaine des machines-outils.

Catégories de produits associés

- presse hydraulique de 100 tonnes

- machine presse hydraulique de 100 tonnes

- machine presse de 100 tonnes

- presse hydraulique de 150 tonnes

- presse de 150 tonnes

- presse hydraulique de 200 tonnes

- presse de 200 tonnes

- presse hydraulique de 300 tonnes

- presse hydraulique de 500 tonnes

- presse de 500 tonnes

- Presse hydraulique industrielle

- Pression du presse hydraulique

Vous ne trouvez pas ce que vous cherchez ?

Contactez nos consultants pour plus de produits disponibles.

Demandez un devis maintenant

Contactez-nous

Droits d'auteur © Nadun Machinery Manufacture Co., Ltd. Tous droits réservés - Politique de confidentialité

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN