Nadun Machinery Manufacture Co., Ltd.

presse plieuse

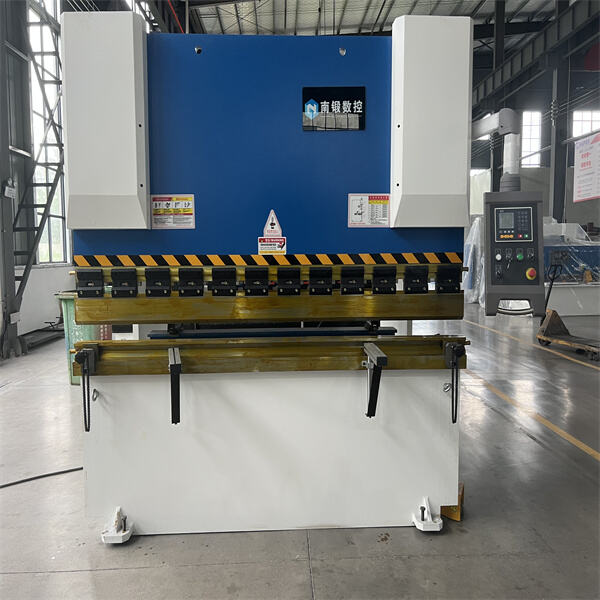

Par exemple, une presse hydraulique de 60 tonnes est une grande machine qui plie le métal en différentes formes. C'est ainsi parce que vous pouvez créer divers objets avec, allant des pièces de voiture et de tuyau jusqu'aux parties d'avion. La presse-plieuse pousse le métal en forme de V en utilisant un outil spécial appelé "moule". Le moule peut être comparé à un modèle, ou une forme qui caste le métal dans la forme que vous voulez. Il s'agit d'un objet lourd capable de manipuler même les métaux les plus épais, ce qui en fait l'idéal pour des pièces qui doivent être solides et durables.

Un plieuse à came est un outil de formage utilisé pour plier des matériaux en feuille et en plaque, le plus couramment de la tôle métallique. Elle possède une grande plaque métallique plate en son dessous, connue sous le nom de table. C'est sur cette table que vous placez la feuille métallique. Un étau permet de maintenir la tôle en position afin qu'elle ne bouge pas pendant que la machine travaille dessus. Une fois que la métal est bien maintenu, un élément appelé poinçon s'abaisse depuis le haut et presse le métal dans le moule. Ce moule est l'outil de formage qui modèle le métal selon le design final que vous souhaitez. En utilisant différents découpes, vous pouvez créer différentes formes. Et c'est ainsi qu'une plieuse à came plie et forme le métal !

Maximiser votre production avec un plieuse à came

Vous pouvez créer des pièces beaucoup plus rapidement avec une presse de 60 tonnes que si vous le faisiez manuellement. C'est essentiel, car le temps dans une usine ou une chaîne de production est précieux. Comparé à une plieuse à came, vous pouvez également créer des formes plus précises et répétables. Cela signifie que plutôt que de passer des heures à façonner chaque pièce à la main, vous êtes capable de produire des milliers de pièces en moins de temps. Voici quelques conseils simples qui permettront à votre plieuse à came de surpasser ses performances :

Choisissez les bons outils - Il est essentiel d'être équipé des outils et matrices appropriés pour la tâche à accomplir. Cela signifie choisir les bons matériaux, l'épaisseur adéquate et les bons angles pour vos pièces afin qu'elles soient fabriquées exactement comme il faut.

-

Les différents types de plieuses à came et leurs applications

Le choix du bon type de plieuse hydraulique dépend de vos exigences spécifiques de projet. Une plieuse mécanique est une bonne option pour de petits travaux, ou lorsque vous n'avez pas besoin de produire beaucoup de pièces. Si vous travaillez avec des matériaux plus lourds ou sur des projets plus importants, une plieuse hydraulique fonctionnera bien mieux. Si vous avez besoin d'une combinaison de vitesse et de précision, alors la plieuse pneumatique est la solution idéale.

-

Assurer des résultats de qualité sur vos projets de plieuse à came

Suivre les dernières techniques et tendances est un autre moyen de garantir la qualité. Vous pouvez lire davantage sur les nouvelles technologies et les meilleures pratiques afin d'améliorer votre production à un autre niveau et travailler de manière plus efficace.

-

Conseils d'entretien pour maintenir votre plieuse à came en bon état

L'entretien régulier de votre presse-plieuse est crucial pour qu'elle reste en bon état de fonctionnement. Cela nécessitera un entretien régulier de la machine afin qu'elle fonctionne correctement et dure longtemps. Vous devez absolument vous occuper des tâches d'entretien suivantes :

Why choose Nadun presse plieuse?

-

Une variété de produits

Pour répondre à la forte demande du marché en matière de produits de refroidissement, les marques Dragon and Tiger et Temple of Heaven proposent une variété de produits pouvant être adaptés à de nombreux types d’utilisateurs et de consommateurs. L’engagement de l’entreprise à devenir un leader industriel dans le domaine de la santé repose sur le développement de gammes de produits de marque, de produits de pliage (press brake) et de l’expérience utilisateur.

-

Qualité de produit fiable

L’entreprise fournit chaque année des services d’installation et de mise en service à plus de 400 clients. Elle fabrique annuellement entre 500 et 600 unités de produits variés. Nos produits sont certifiés selon les normes ISO, CE, SGS et d’autres certifications. Notre engagement en faveur de l’excellence se traduit par de nombreux brevets déposés dans le domaine de l’innovation pour nos produits, ainsi que par les distinctions honorifiques (« press brake of honor ») que nous avons reçues.

-

Expertise de l'entreprise et présence mondiale :

Avec plus de 17 ans d’expérience, Nadun Machinery s’est imposée comme un fabricant et exportateur leader dans le domaine du travail des métaux. Nous nous spécialisons dans les presses à poinçonner et les presses hydrauliques. Nous fournissons également des machines à ciseler et des machines à plier. Nos produits sont commercialisés dans plus de 150 pays et régions à travers le monde, établissant de nouvelles références en matière de machines plieuses.

-

Qualité et Performance Exceptionnelles :

Les produits Nadun Machinery sont réputés pour leur qualité supérieure, leurs performances excellentes et leur longue durée de vie. L’entreprise abrite une équipe de recherche et de développement dédiée aux plieuses, comptant plus de dix membres, chacun possédant en moyenne plus de 10 ans d’expérience dans la recherche et le développement. Notre équipe innove et s’améliore constamment afin de répondre aux exigences changeantes du marché.

Catégories de produits associés

- presse hydraulique de 100 tonnes

- machine presse hydraulique de 100 tonnes

- machine presse de 100 tonnes

- presse hydraulique de 150 tonnes

- presse de 150 tonnes

- presse hydraulique de 200 tonnes

- presse de 200 tonnes

- presse hydraulique de 300 tonnes

- presse hydraulique de 500 tonnes

- presse de 500 tonnes

- La presse hydraulique

- Machine de forge à froid

Vous ne trouvez pas ce que vous cherchez ?

Contactez nos consultants pour plus de produits disponibles.

Demandez un devis maintenant

Contactez-nous

Droits d'auteur © Nadun Machinery Manufacture Co., Ltd. Tous droits réservés - Politique de confidentialité

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN