|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

Model Number: |

YM-500T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

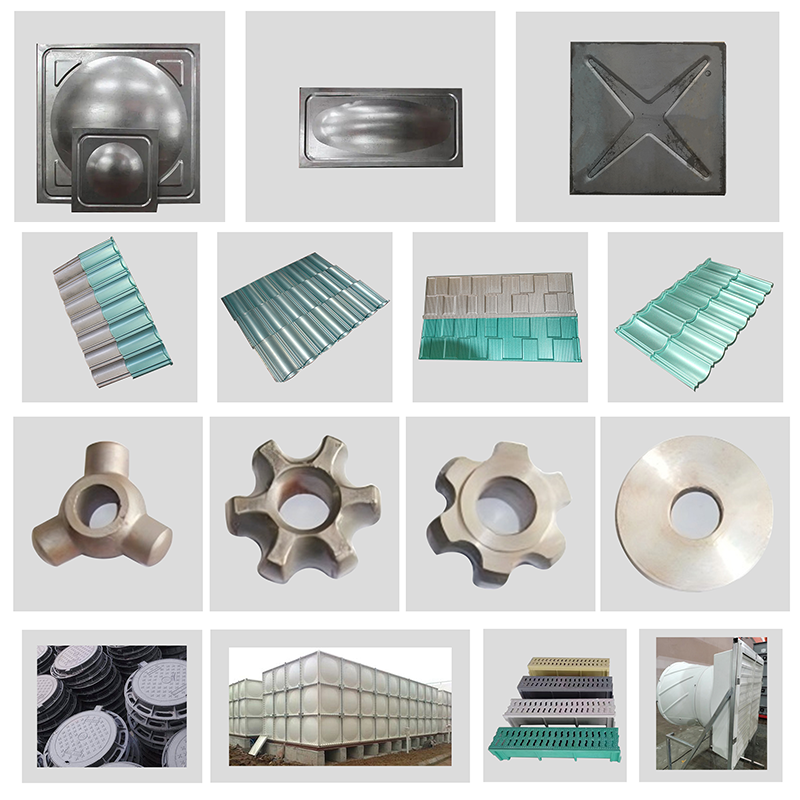

Frame hydraulic press (also known as frame hydraulic press) is a rigid frame structure as the core load-bearing body of the hydraulic transmission pressure equipment, through the liquid pressure transfer of energy, to achieve the metal, non-metallic materials, such as pressing, molding, stretching and other processes.

High rigidity frame design: the use of integral welding or casting molding frame structure, to avoid the traditional threaded connection of the nut loosening problem, the body deformation is small, long-term operation of the accuracy of good retention.

High rigidity frame design.

Strong anti-bias load capacity: four corners and eight surfaces guide rail guide, the gap can be adjusted, can effectively resist lateral thrust; combined frame structure, the column only bear bending moment, the tie rod bear tensile force, anti-fatigue performance is significantly improved.

The combination frame structure, the columns only bear the bending moment, the tie rods bear the tension force, the fatigue resistance performance is significantly improved.

Rapid pressure starting performance: it takes only about 1 second to rise to the rated pressure after closing the mold, which is suitable for the rapid cycle in mass production and improves the production efficiency.

High Process Flexibility

Automotive industry: stretching, stamping and straightening of automotive parts (such as steel rims, body covering parts, chassis parts, door impact beams).

Household appliances and daily necessities: stainless steel tableware, kitchenware, home appliance shell (such as refrigerator door plate, washing machine inner cylinder), metal cases, locks of the press molding.

Powder metallurgy and new materials: thermosetting composite materials such as SMC, BMC, DMC, and the molding of lightweight materials such as aluminum alloy and magnesium alloy.

Machinery and hardware: pressing of mechanical parts such as bearings, flanges, crossheads, universal joints, etc.; extrusion molding of agricultural machinery parts (such as plow knives and blades) and mining cut-off teeth.

Molds and calibration: mold debugging, small batch trial production; metal workpiece leveling, calibration (such as correction of deformed steel plate, shaft parts.).

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy