|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

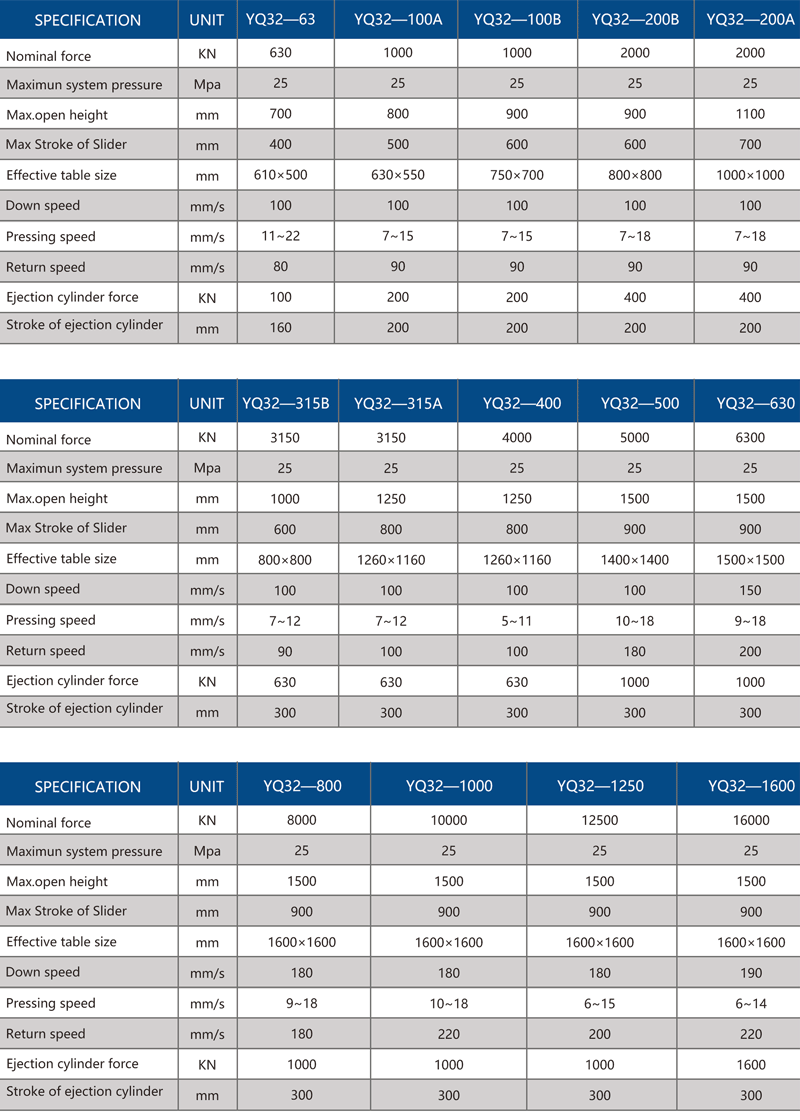

Model Number: |

YQ32-315T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

Carbon fiber hot presses utilize high-temperature, high-pressure curing processes to precisely control the geometric accuracy, dynamic balance, and fiber layup structure of propeller blades. This significantly enhances their strength, stiffness, corrosion resistance, and fatigue performance while achieving lightweight objectives, making them core equipment for manufacturing drone propeller blades.

Precision Temperature Control System: Utilizes a multi-zone independent heating system, maintaining overall temperature variation within ±3°C. Combined with segmented heating curves, it achieves optimal resin curing.

Automated Control: Features PLC and touchscreen human-machine interface, enabling the setup and storage of multi-stage curing process curves. Parameters include heating rate, target temperature, holding time, and pressure values, with fully automated control throughout the entire process.

Primary Application Fields

Aerospace: Drone airframes/wings, satellite components, aircraft interior parts, secondary load-bearing structural elements.

New Energy Vehicles: Battery box lids/lower housings, doors, roof panels, chassis structural components (e.g., A/B-pillar reinforcement plates), hydrogen storage tanks.

Rail Transportation: High-speed rail/subway front cowlings, interior panels, equipment compartments.

High-End Sports Equipment: Bicycle frames, fishing rods, racquets, rowing machine components.

Industrial & Medical: Robotic arms, CT scanner tables, prosthetic limbs.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy