|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

Model Number: |

YQ32-630T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

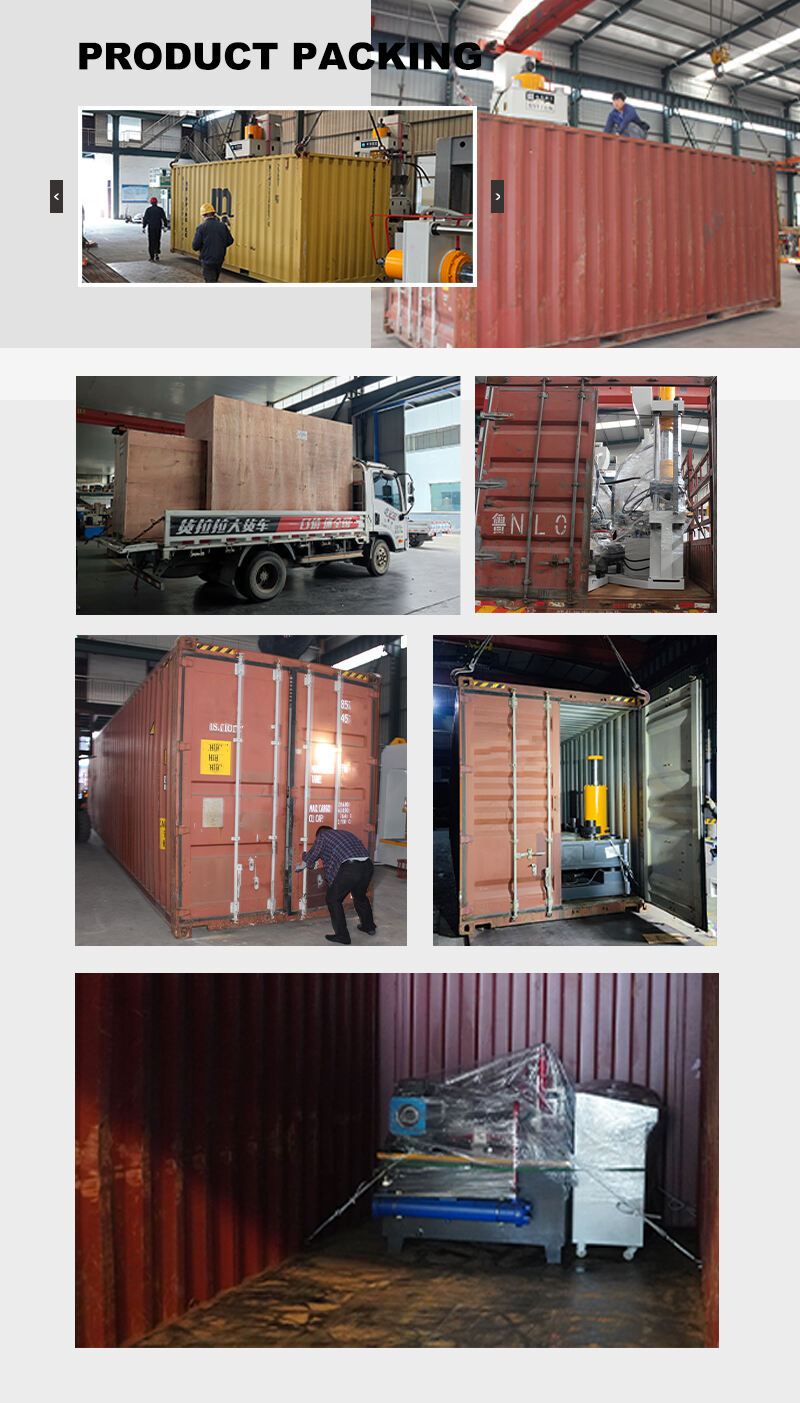

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

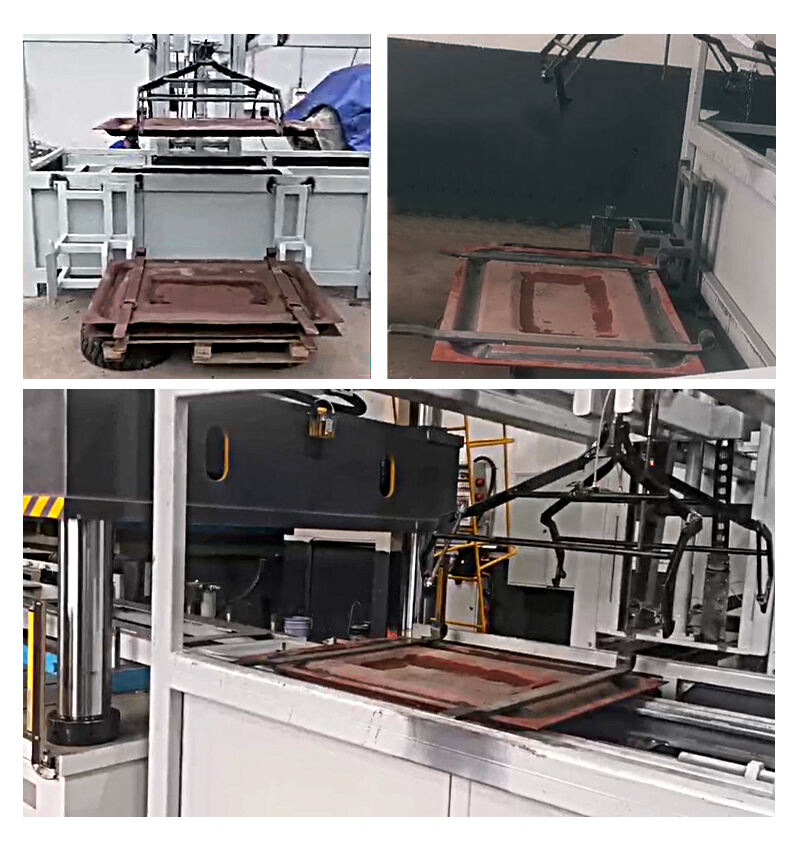

Train Door Panel Shaping Press is a calibration equipment used for train (including high speed railroad, moving train, common speed train, etc.) door panels when deformation occurs in the process of manufacturing or repairing.Its core role is to restore the designed shape and dimensional accuracy of the deformed door panel by applying controlled pressure to ensure smooth door opening and closing, sealing and appearance quality.

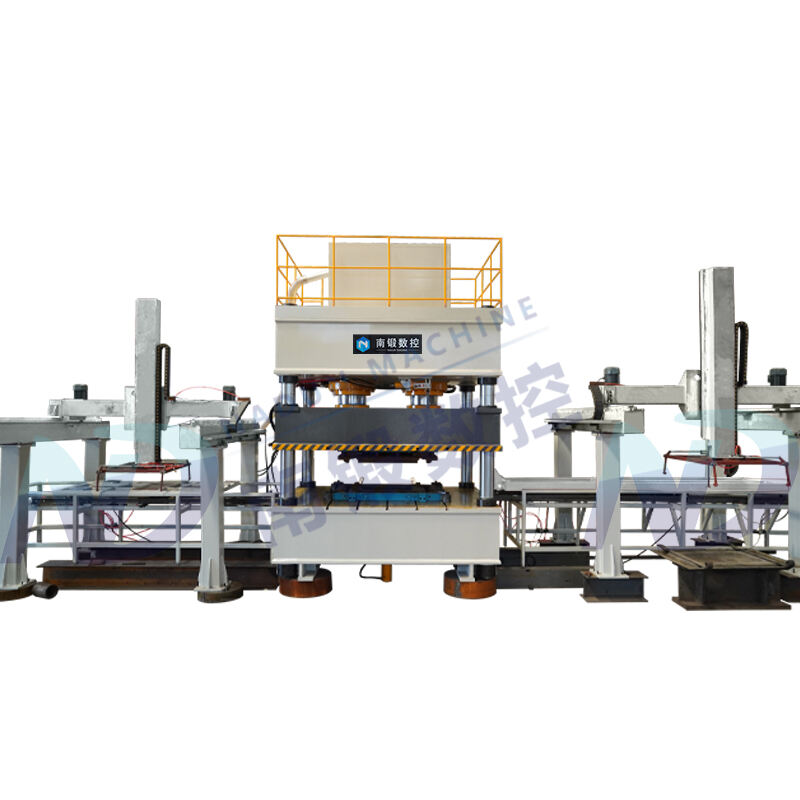

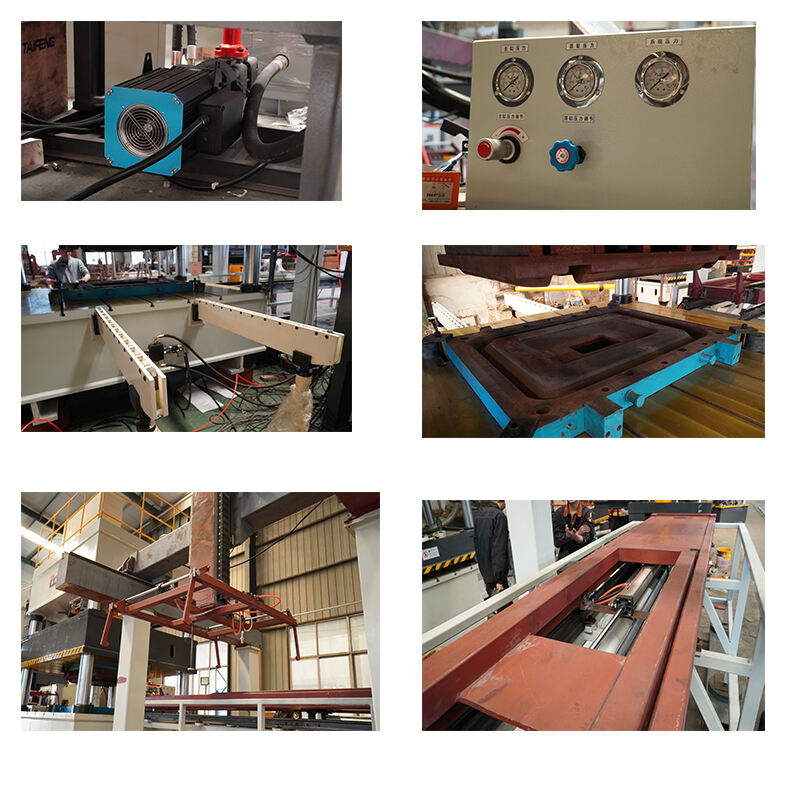

Train door plate shaping hydraulic press usually adopts three-beam and four-column structure, which is composed of core parts such as machine body, main cylinder, top cylinder, and range-limiting device.

It supports the integration of multiple processes such as punching & cutting & dropping, stretch molding, bending, embossing, etc. It can be adapted to different metal plate characteristics by adjusting the parameters such as pressure and downward pressure speed.We can provide automated production line: supporting automatic auxiliary equipment: robot, conveyor belt .All steps can be automated, from handling the workpiece to the completion of pressing to removing the workpiece, to palletizing.This saves labor costs and improves work efficiency.

From high-speed moving train to general-speed bus, from subway to overseas railroad projects, the application scenario of train door shaping hydraulic press is very wide:

Dynamic train section/high-speed railroad vehicle section: to repair the oval deformation of door frame and sagging of door body of high-speed dynamic train set sliding door;

General-speed train maintenance base: dealing with the weld cracking and door body distortion of the steel swing door of passenger cars;

Subway vehicle section: correcting the excessive gap between door frame and car body caused by frequent opening and closing of the inner hidden door of subway cars;

Applicable to a variety of workpiece shaping, metal pressing molding process。

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy