Nadun Machinery Manufacture Co., Ltd.

მექანიკური ჭრის მაშინი

Დაარ Gaussian თუ რა გამოიფიქრეთ იმის შესახებ, თუ როგორ წარმოიდგენენ მეტალურGI ნაწილები ფაბრიკებში? ჭრილის მოსამართლებისგან ზომამდე, მექანიკური ჭრილი არის ძალიან პრაქტიკული ასეტი მუშაობელებისთვის, რომ შეძლონ მეტალი ჭრა, როგორც განსხვავებული ფორმებისა და ზომების მიხედვით. მართლაც მას შეუძლია მისი მსგავსი იყოს დიდი წყვილი, რომელიც ჭრის მეტალურGI ფერაში!

Წარმოიდგინეთ მოწყობილი, რომელიც არის ორი სუპერ მწვანე წყვილი. რათა ჭრას მეტალი, მუშაობელები ადგილებს შენ ეს ორი წყვილის შორის. შემდეგ, ისინი წვდობიან ზედა წყვილზე. წყვილი ასე ძალიან ძალიანია, რომ ის გადის მეტალის მასში და ქმნის ზუსტად იმ ფორმას, რომელიც ისინი გსურთ. ეს წყვილები სPECIAL არის, რომლებიც შემოქმედებიან ხარისხიან მასის მეტალის, დაბალი წინააღმდეგობის და შეძლების მეტალის ჭრას მარტივად და ერთსაგული.

Მექანიკური ჭრის მაशინის მოდის და შეზღუდვების გასაგები.

Ეს სასარგებლო მანქანა არის სამწარმოებელო და მუშაობის სახლებში სრული სუპერგმირი. ის შეძლებს მეტალურგიული ფლანგების ჭრა რამდენიმე ფორმაში და ზომაში. ისინი იყენებენ ეს მანქანებს ყველაფერის წარმოებისთვის, რაც ჩვენ ყოველდღიურად გამოვიყენებთ. A მექანიკური ჭრილი იწყებს ათასამდე ნაწილს, რომლებსაც ჩვენ ყოველდღიურად გამოვიყენებთ - ავტომობილები, გზის ნიშნები, სამზარეულო იнструმენტები, და ნახსნები კომპიუტერის კომპონენტები.

Რაც კიდევ უფრო საინტერესოა ამ კონკრეტულ მაशინაზე, ის მისი სწრაფი მუშაობის მიმართულებაა. ის შეძლებს წუთებში დაჭრას ბევრი მეტალის ნაწილად. ეს შეადგენს მუშაობის ხანგრძლივად და დიდ რაოდენობის რამეს წარმოებას. ზოგიერთი დაჭრის ღრუბელ და მძლავრ მეტალს; ზოგიერთი, განმავლობით მარტივ მეტალის ფერდებს.

-

Მეტალის ჭრის საჭიროებისთვის სწორი მექანიკური ჭრის მაშინის არჩევა.

Ეს არ არის თამაში, რომელიც თქვენ თამაშობთ. ის მოითხოვს სპეციალურ განათლებას და ბევრ ყურადღებას. მხოლოდ გამოსახატული მეცნიერები უნდა იყენებენ ელექტრო დაჭრის მაशინას. ჩანართები საკმარისად მწარმოა, და მაშინა ძალიან ძალიან მძლავრია. ერთ-ერთი მცდარი შეცდომა შეიძლება იყოს საშიში.

-

Მექანიკური ჭრის მაშინებში ხშირი პრობლემების გამოსავალი.

Ამ მაშინას მოითხოვს სპეციალური მომსახურება, როგორც მანქანას მას სხვადასხვა ზედა ცვლის მოთხოვნა. მუშაობებს უნდა ხელმისაწვდომად წაშალონ მაშინა წნევით. ისინი შეამოწმებენ ჩანართებს, რომ დარწმუნდნენ, რომ ისინი წარმართლებულია და არ არის გაწვრივებული. თუ რაღაც არ ჩანს სწორი, ისინი მოიხსენებენ ექსპერტს, რომ მან დაეხმაროს მაშინის починкаში. ყველაფერის კარგი მდგომარეობის მარტივი მოხდენა მაშინას უფრო კარგად და გრძელად მუშაობს.

-

Მექანიკური ჭრის მაშინის მარტივი მარცხენა და სერვისი უკეთესი მუშაობისთვის.

Არ არის ტოლი ყველა მექანიკური ჭრილის მანქანა. ზოგი დიდია, ზოგი პატარა. ზოგი შეძლებს ცხელი მეტალურGI ფერაში ჭრას, ხოლო სხვები შეძლებს ჭრას მაღალი მეტალის. მუშაობელები აირჩევენ სწორ მანქანას იმით, რაც უნდა წარმოიდგინონ. ეს მართლაც მსგავსია სწორი იнструმენტის არჩევას კონკრეტული სამუშაოსთვის.

Why choose Nadun მექანიკური ჭრის მაშინი?

-

Მაღალი ხარისხი და შესაბამისი შესაბამისი:

Nadun Machinery-ის პროდუქტები ცნობილია მათი მაღალი ხარისხით, გამორჩეული შესრულებით და გრძელი სამსახურო ვადით. კომპანიის კვლევისა და დიზაინის გუნდში შედის 10-ზე მეტი მეхანიკური გადაჭრის მანქანა, რომელთა თითოეულს აქვს კვლევისა და განვითარების სფეროში 10 წელზე მეტი გამოცდილობა. ჩვენი გუნდი ყოველთვის ამიღებს გაუმჯობესების და ინოვაციების გზას, რათა მიერწიოს მეტალურგიის ბაზრის მენეჯმენტის ცვლილებებს.

-

Კომპანიის ექსპერტიზა და გლობალური მასშტაბი:

17 წელზე მეტი გამოცდილობის მქონე Nadun Machinery-ის მეхანიკური გადაჭრის მანქანები მეტალურგიის დამუშავების სფეროში ცნობილი ექსპორტიორი და წარმოებლის სტატუსით აღიარებულია. ჩვენ ვაკენტრებთ პანჩ პრესებზე, ჰიდრავლიკურ პრესებზე, გადაჭრის და გამოხრის მანქანებზე და ვერტიკალურ ტორნებზე, რომლებიც ემსახურებიან სხვადასხვა სამრეწველო სფეროს, მათ შორის ავტომობილების წარმოებას, აეროკოსმოსურ სამრეწველოს, მექანიკურ ინჟინერიას, საშენო მრეწველოს და მეტალურგიას. ჩვენი პროდუქტები გაყიდულია მსოფლიოს 150-ზე მეტ ქვეყანაში და აყენებენ ახალ სტანდარტებს მანქანათმშენებლობის სფეროში.

-

Მั่นคงი პროდუქტის ხარისხი

Ჩვენი კომპანია წლიურად წარმოებს 500–600 კომპლექტს (კომპლექტს) სხვადასხვა პროდუქტისგან. ასევე, წლიურად ვაკეთებთ მომხმარებლების 400-ზე მეტი სადგურის მონტაჟსა და გაშვებას. პროდუქტებმა მიიღეს ISO, CE, SGS და სხვა სერტიფიკატები. ჩვენ გვაქვს რამდენიმე პროდუქტის ინოვაციური პატენტი და საპატიო სერტიფიკატი, რომელიც მეхანიკური გამოკვეთის მანქანის სრულ perfection-ზე მიუთითებს.

-

Მრავალფეროვანი პროდუქცია

Გამოსაყენებლად გამოყენების პროდუქტების მოთხოვნის ზრდის დასაკმაყოფილებლად, «Dragon and Tiger» და «Temple of Heaven» მეхანიკური გამოკვეთის მანქანები სთავაზობენ სავარიაციო ასორტიმენტს, რომელიც შესაძლებელია მორგება სხვადასხვა ტიპის მომხმარებლებსა და მომხმარებლებზე. კომპანიის გადაწყვიტება ჯანმრთელობის სფეროში ელიტური კომპანიის სტატუსის მისაღებლად დაფუძნებულია ჯანმრთელობისა და კეთილდღეობის ბრენდირებული პროდუქტების და მომხმარებლის გამოცდილების განვითარებაზე.

Დაკავშირებული პროდუქტის კატეგორიები

- Მექანიკური ჩატრის მანქანა

- Მექანიკური პრესის მანქანა

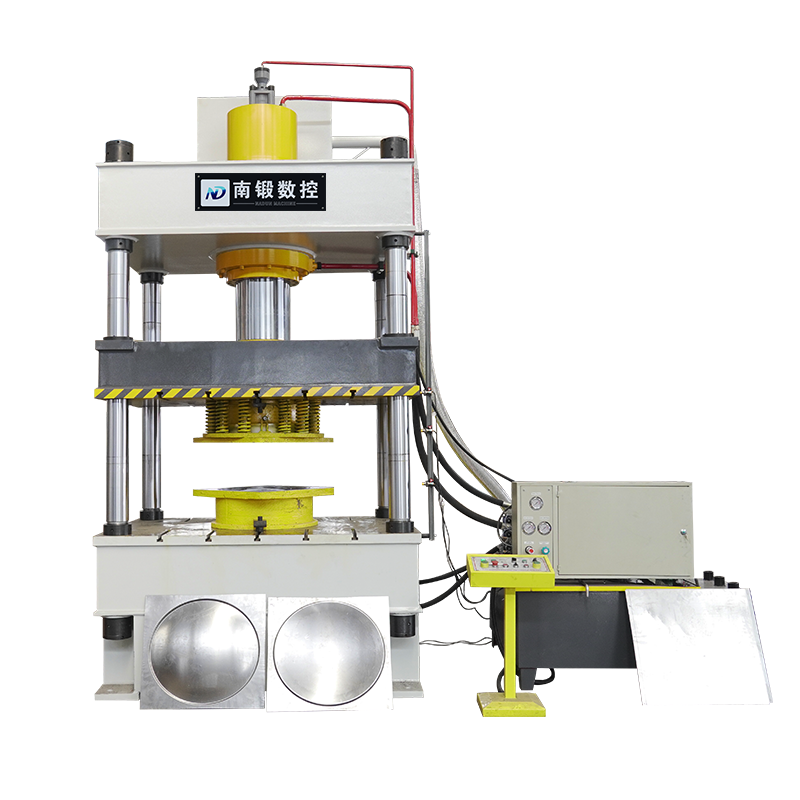

- Დიდი ჰიდრაულიკური წნევის მანქანა

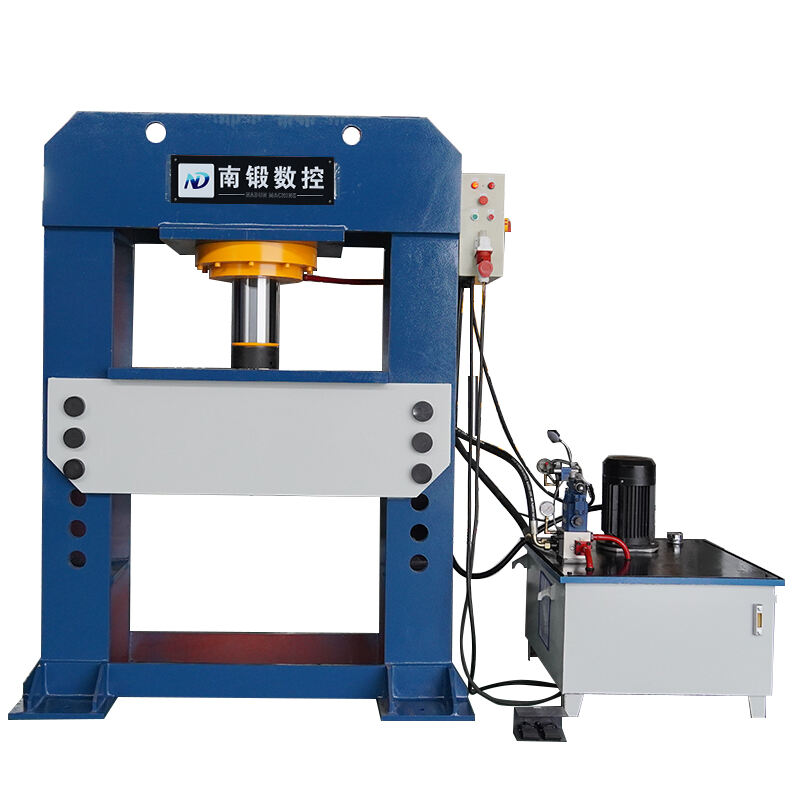

- Ჰიდრაულური წნევის მაშინე

- Ჰიდრაულიკური პრესი მახვილებისთვის

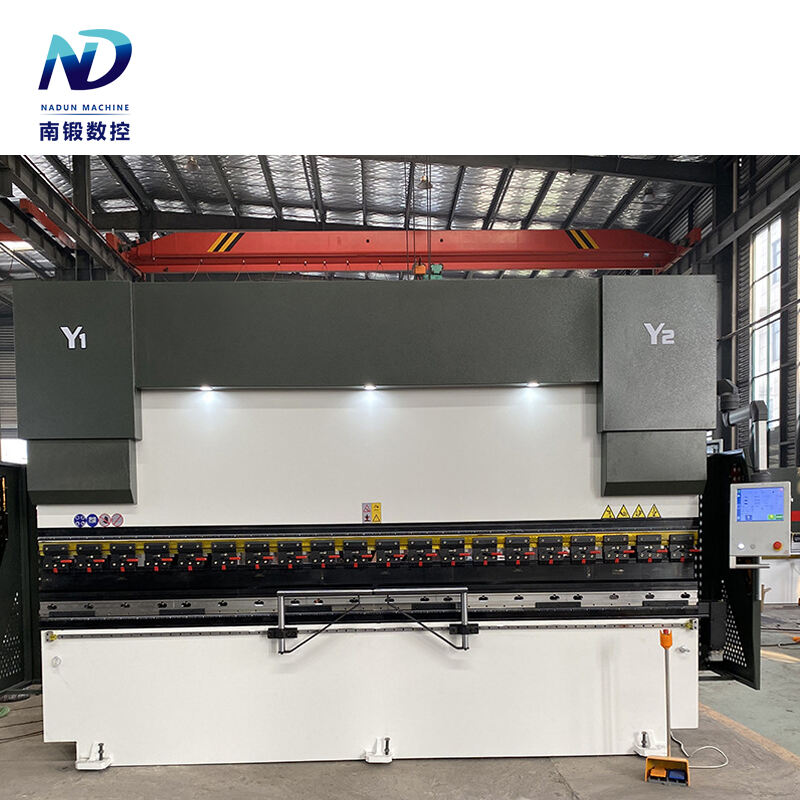

- Მეტალურგიული ბრეიკი ჰიდროლიკული მაჭვისთვის

- Ძაღლის მაშინა

- Nc press brake

- 椽ის მოდელირების მანქანა

- Მეტალის გამრუდების ბრეკები

- 100 トん ჟიდესპირის მანიტის მაशინა

- Ჰიდრაულიკური ცხვირი თერმოპრესი

Ნვ ნაოპაგთრვ ქრჲ რპწბგაქ?

Სვანეთსა და კვანძში

Მოთხოვნა ციფრით

Დაუკავშირდით

Ავტორის უფლებები © Nadun Machinery Manufacture Co., Ltd. ყველა უფლება დაცულია - Პირადულობის პოლიტიკა

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN