|

Gamtos vieta: |

Tengzhou Kinija |

|

Branduolinis pavadinimas: |

Nadun |

|

Modelio numeris: |

YQ32-400T |

|

Sertifikacija: |

CE ISO |

|

Minimalus užsakymo kiekis: |

1 |

|

Packaging Details: |

Pavyzdys apima hidraulinią spaudinę ir formą. Norėdami gauti daugiau informacijos, susisiekite su mumis. |

|

Pristatymo laikas: |

15-45 dienos |

|

Mokėjimo sąlygos: |

L/C D/P D/A T/T |

|

Priežiūros galimybė: |

50vnt/m |

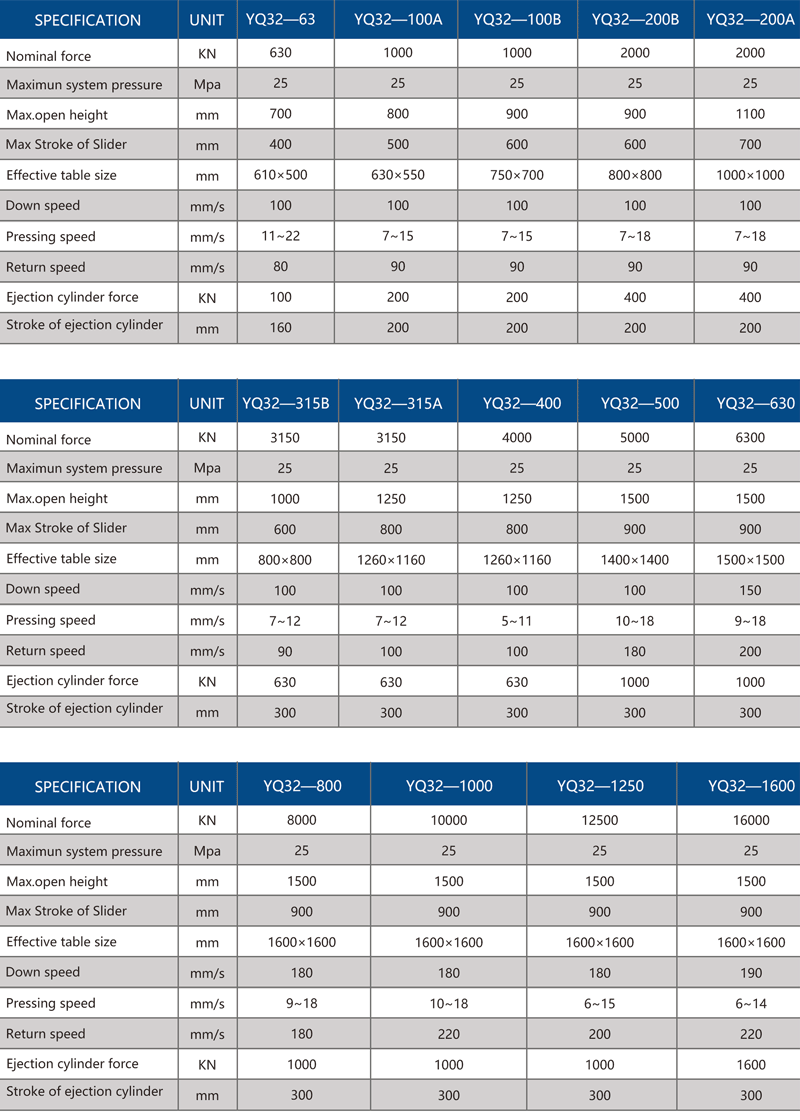

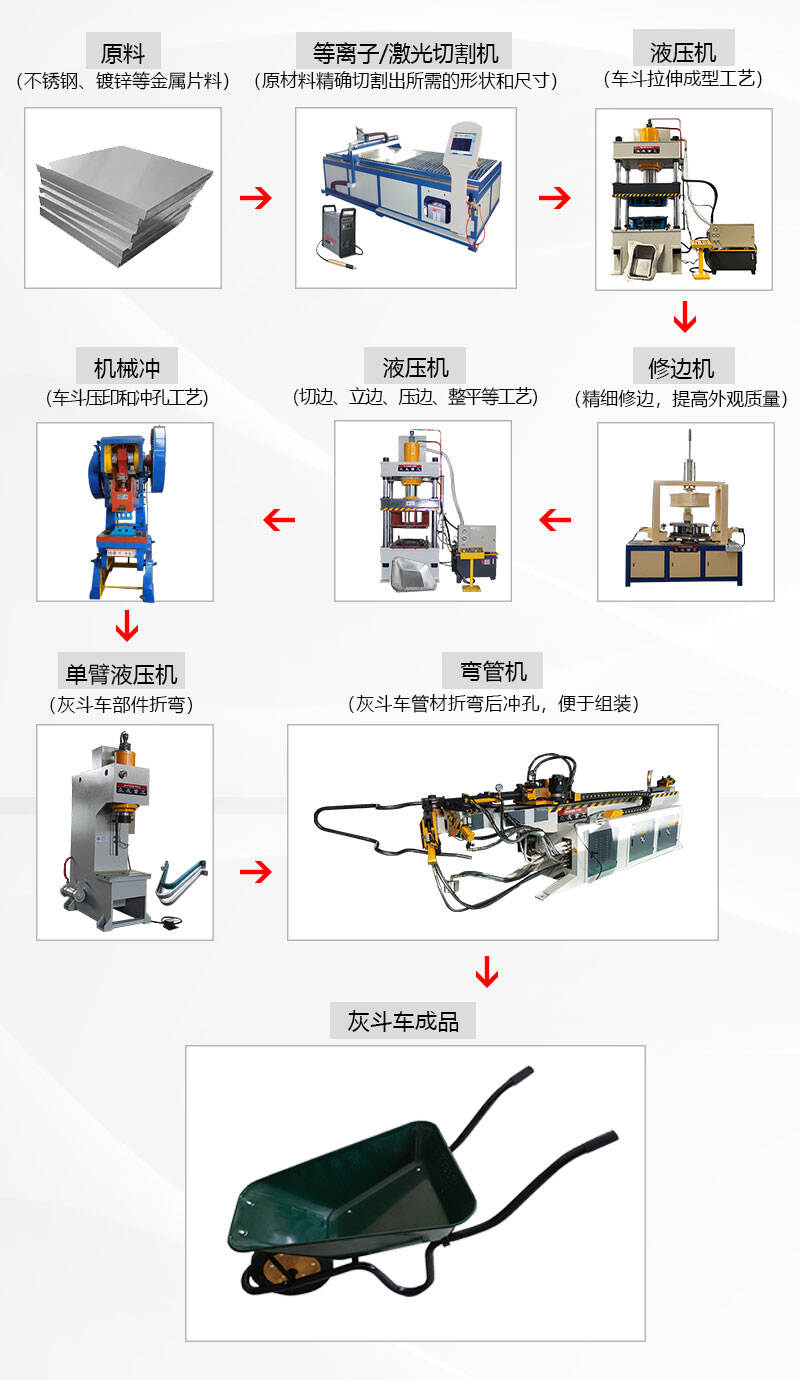

400 tonų hidraulinis presas pelenų bakams skirtas specializuota hidraulinė įranga, sukurtą vežimėlių (pelenų bakų) formavimui statybos aikštelėse. Turintis trijų sijų, keturių stulpų konstrukciją, jis naudoja hidraulinę sistemą, kad pasiektų vientiso temptinio formavimo procesą pelenų bakams.

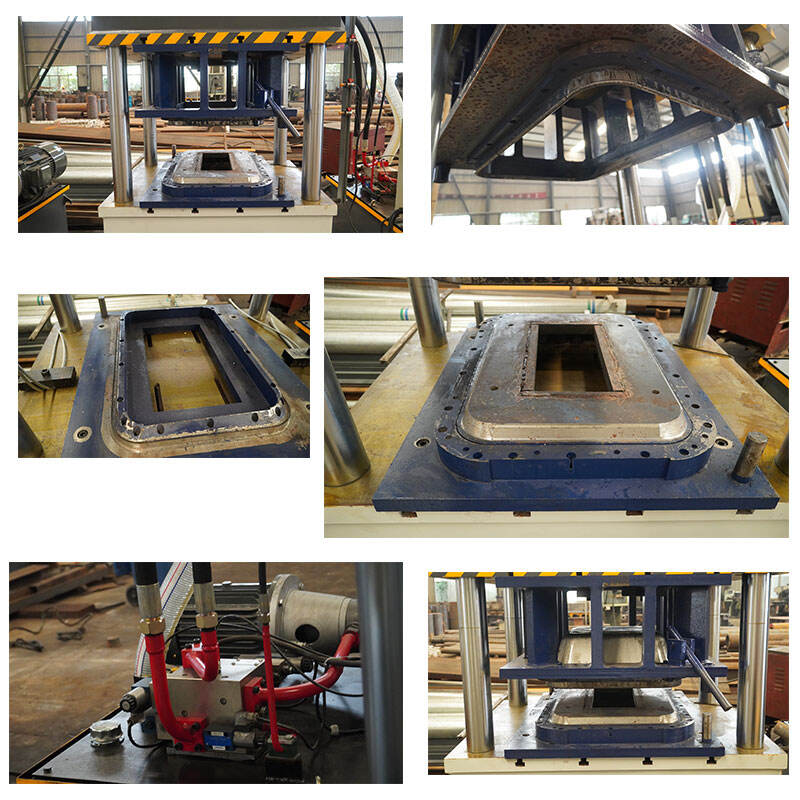

Rėmo konstrukcija: trys sijos, keturi stulpai, iš viso plieno plokštės sujungtos CO₂ suvirinimo būdu. Po suvirinimo atliekamas įtempties mažinimas ir vibracinis apdorojimas, užtikrinantys ilgalaikę rėmo stabilumą. Keturių stulpų dizainas užtikrina paprastumą, kainos našumą, puikią standumą ir tikslumo išlaikymą.

Hidraulinė sistema: naudoja kartučių vožtuvų integruotą sistemą hidrauliniam valdymui, kuris užtikrina mažą smūgį, patikimą veikimą, ilgesnį tarnavimo laiką ir minimalius nutekėjimo taškus. Nauji cilindrų tarpikliai užtikrina aukštą patikimumą ir ilgesnį tarnavimo laiką. Traukimo ir želėjimo slankikliai gali būti sujungti į vieną vienetą, kad atliktų vieno veiksmo formavimo operacijas.

Elektrinė sistema: PLC pagrindu veikiantis automatinis valdymas su rankiniu reguliavimu (jog) ir pusiau automatinėmis funkcijomis. Gali atlikti pastovaus slėgio ir pastovaus eigos formavimo procesus, turi reguliuojamą slėgio išlaikymo delsos trukmę. Darbinis slėgis ir eiga gali būti reguliuojami nurodytuose ribose atsižvelgiant į technologinius reikalavimus.

Pelenų bunkerių gamyba: ištempti nerūdijančio plieno / metalo lakštų bunkeriai pasiekia vientisą, didelės stiprybės formavimą.

Metalų apdorojimas: miltelių metalurgija, šaltas ekstruzija, presavimas, kraštinimo formavimas, išlyginimas – tinka titano lydinio kalimui ir reaktyvaus variklio dalių giliniam formavimui.

Kompozitai ir plastikai: anglies pluošto SMC kompresija, plastikinių talpų karštas presavimas, aliuminio-plastiko kompozitų pakuotės sandarinimas.

Statyba ir aplinkos apsauga: cemento blokų / šlako plytų presavimas, statybų atliekų perdirbimas (pvz., skraidžiųjų pelenų plytų gamyba).

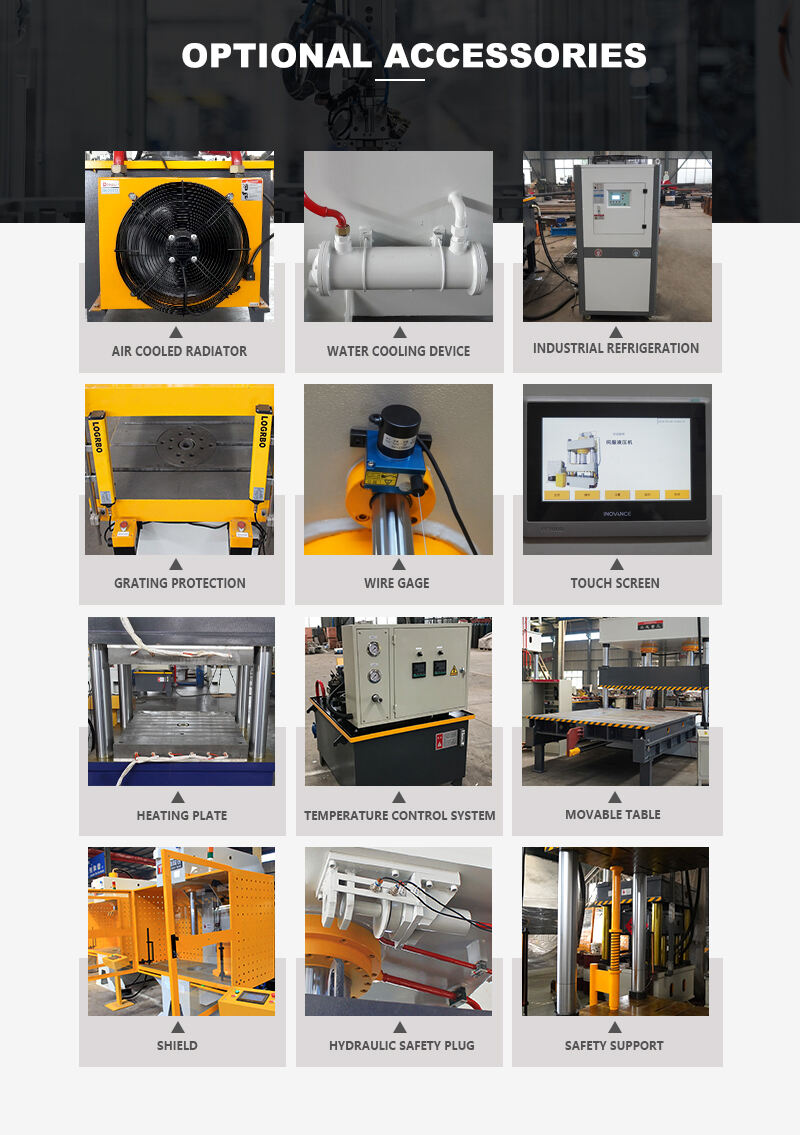

Mes teikiame visapusiškas paskelbimo paslaugas, įskaitant montavimą, paleidimą ir eksploatacijos mokymus; pateikiamos presų naudotojo instrukcijos, kad būtų lengviau išmokti, kaip naudoti ir prižiūrėti preso mašinas.

Mes siūlome pilną hidraulinio preso įrenginių rinkinį su daugybe brandžių projektavimo sprendimų ir sėkmingų klientų atvejų. Taip pat siūlome individualizuotą aptarnavimą kartu su formavimo įrankiais ir atitinkamais gamybos linijų įrenginiais, teikiant klientams vieno stogų paslaugas. Kviečiame mus paskambinti dėl konsultacijos.

Mūsų draugiška komanda norėtų girdėti nuo jūsų!

Autorinių teisių sauga © Nadun Machinery Manufacture Co., Ltd. Visos teisės saugomos - Privatumo politika