|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

Model Number: |

YQ32-200T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

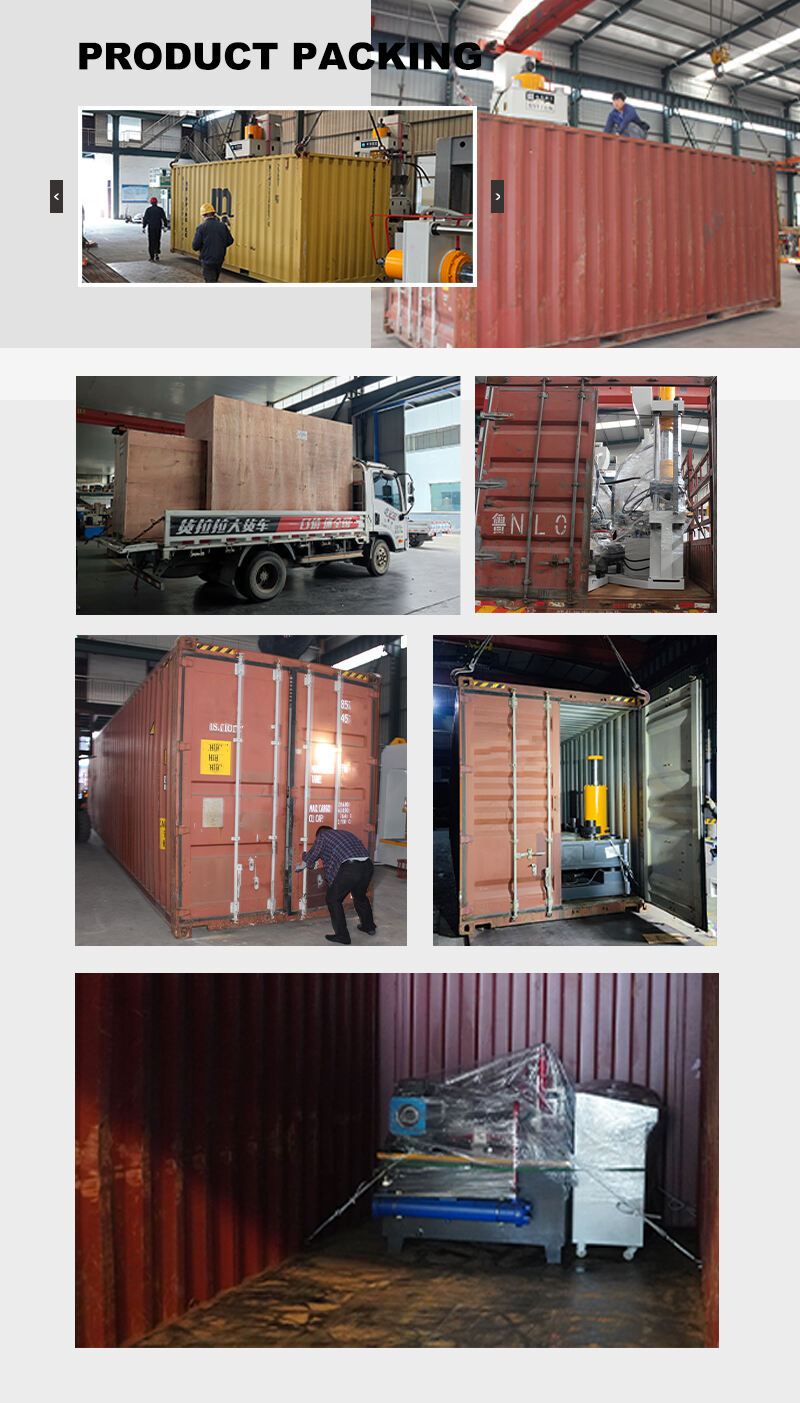

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

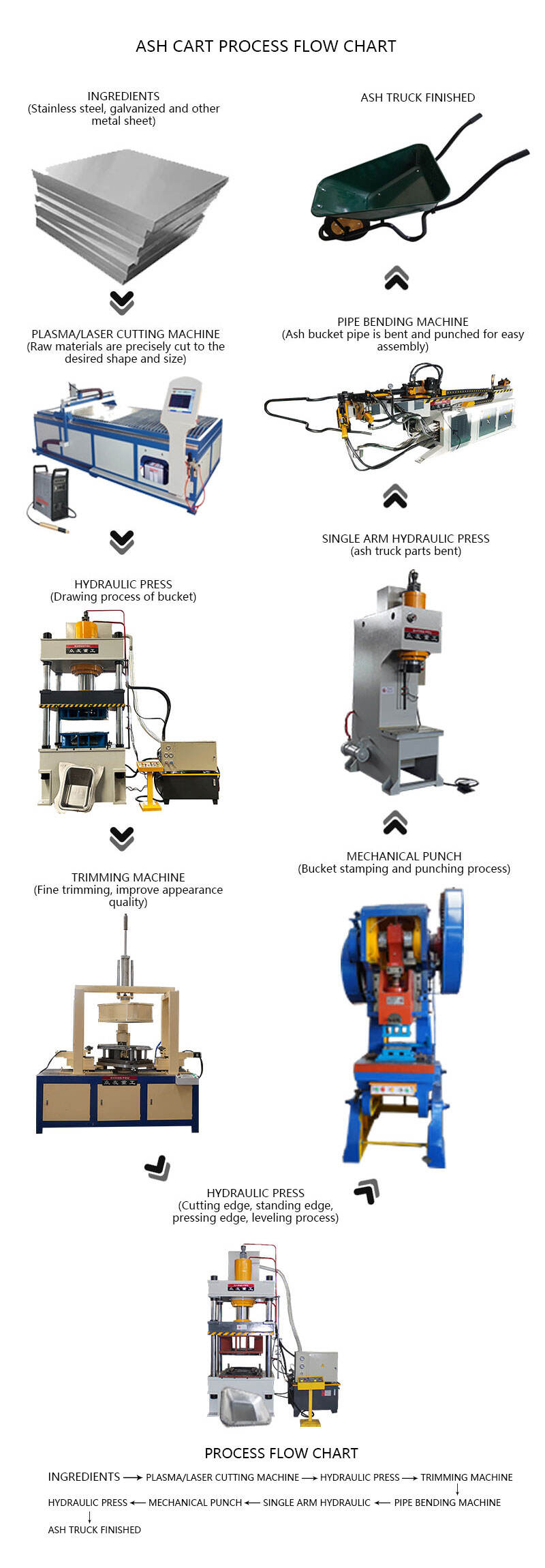

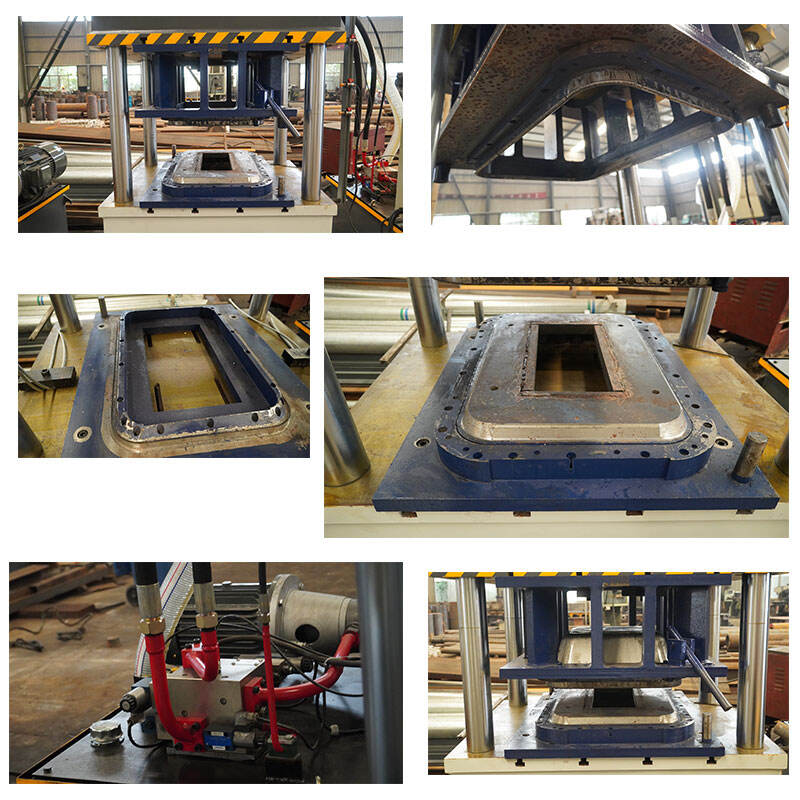

This 200-ton three-beam four-column hydraulic press is a special equipment designed for shaping the edges of ash hopper trucks' hoppers. It realizes the operations of stretching, flanging and crimping of metal plates through high-pressure molding process, which makes the edges of the hoppers smooth, solid and sealed.

| Name | Unit | YQ32-400 | YQ32-500 | YQ32-630 | YQ32-800 | YQ32-1000 | YQ32-1250 | YQ32-1600 |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Maximum Stroke of Slider | mm | 800 | 900 | 900 | 900 | 900 | 900 | 900 |

| Effective Area of Workbench | mm | 1250×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 | 1600×1600 | 1600×1600 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 150 | 100 | 180 | 180 | 190 |

| Pressing Speed | mm/s | 5-11 | 10-18 | 9-18 | 7-18 | 10-18 | 6-15 | 6-14 |

| Return Speed | mm/s | 100 | 180 | 200 | 90 | 220 | 200 | 220 |

| Ejecting Force | kN | 630 | 1000 | 1000 | 400 | 1000 | 1000 | 1600 |

| Maximum Ejecting Stroke | mm | 300 | 300 | 300 | 200 | 300 | 300 | 300 |

| Parameter | Unit | YQ32-63 | YQ32-100A | YQ32-100B | YQ32-200A | YQ32-200B | YQ32-315A | YQ32-315B |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 700 | 800 | 900 | 1100 | 900 | 1250 | 1000 |

| Maximum Stroke of Slider | mm | 400 | 500 | 600 | 500 | 600 | 800 | 600 |

| Effective Area of Workbench | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing Speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return Speed | mm/s | 80 | 90 | 90 | 90 | 90 | 100 | 90 |

| Ejecting Force | kN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Maximum Ejecting Stroke | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

Multi-process compatibility:

It is suitable for metal material pressing process, such as stamping, bending, flanging, thin plate stretching and metal parts press fitting, calibrating, cold extrusion and so on.

It can also realize the press molding process of plastic products and powder products to meet the diversified needs of the edge shaping of ash hopper trucks.

Adjustability:

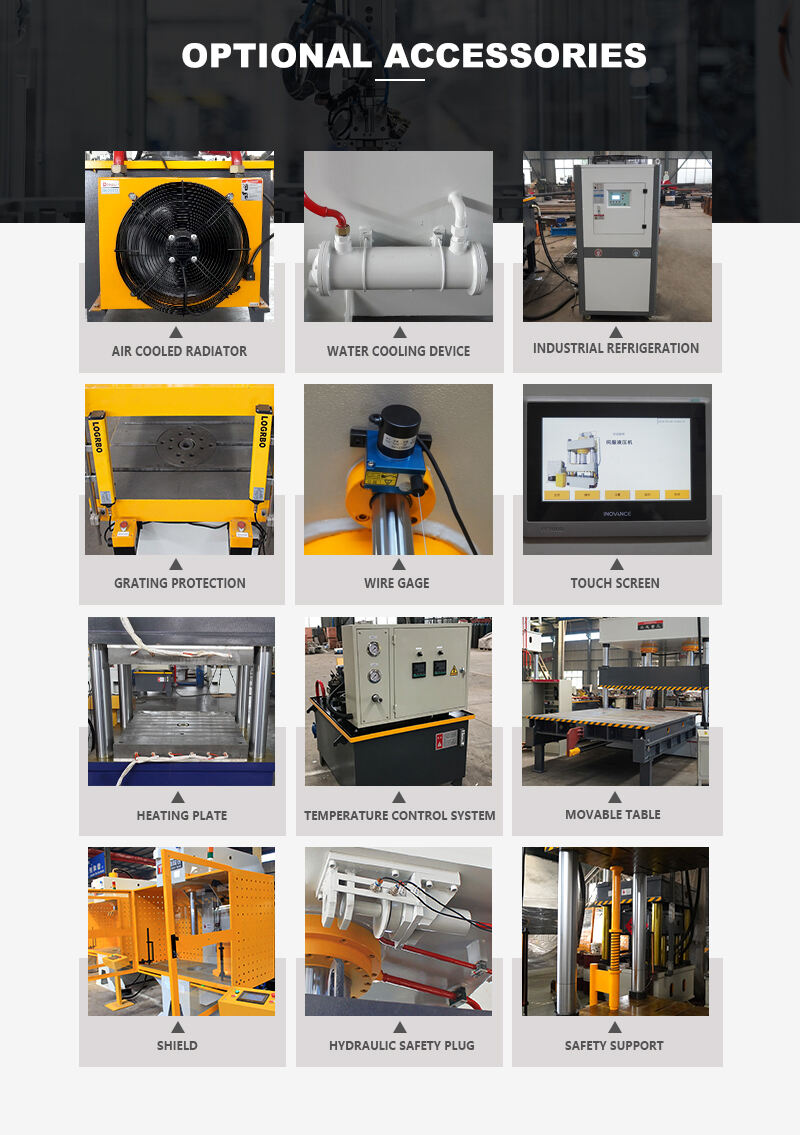

The working pressure, pressing speed and slide stroke can be adjusted according to the process needs.

It can accomplish three kinds of processes: ejector process, non-ejector process and stretching process, and each process provides two kinds of process actions for choice: fixed pressure and fixed stroke.

Reverse stretching process:

Adopting counter-stretching molding process makes the edge of the ash hopper truck more flat and smooth, and improves the quality of the product.

Hydraulic pads can be installed in or outside the working table to meet the needs of different specifications of the production of gray hopper trucks.

Grey Bucket Truck Edge Shaping Hydraulic Press is a special equipment designed for shaping the edge of the bucket of the Grey Bucket Truck, which realizes the operation of stretching, flanging, and curling of the metal plate through high-pressure molding process to make the edges of the bucket smooth, solid, and strong sealing.:

Sheet Metal Stretching: Stretch the flat metal material into the curved or tapered structure required by the car bucket.

Edge shaping: Flanging and crimping the edges of the hopper through molds to enhance the structural strength and prevent material leakage.

Automated production: support pointing and semi-automatic operation modes, and the stroke, pressure and speed of each running part are adjustable to meet the production requirements of different specifications of car buckets.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy