|

Tempat Asal: |

Tengzhou China |

|

Nama Brand: |

Nadun |

|

Nombor Model: |

YM-160T |

|

Penyeliaan: |

CE ISO |

|

Kuantiti Pesanan Minimum: |

1 |

|

Butir-butir Pemakanan: |

Contoh termasuk tekanan hidraulik dan cetakan. Sila hubungi kami untuk maklumat lanjut. |

|

Masa Penghantaran: |

15-45 hari |

|

Syarat Pembayaran: |

L/C D/P D/A T/T |

|

Kemampuan Bekalan: |

50set/m |

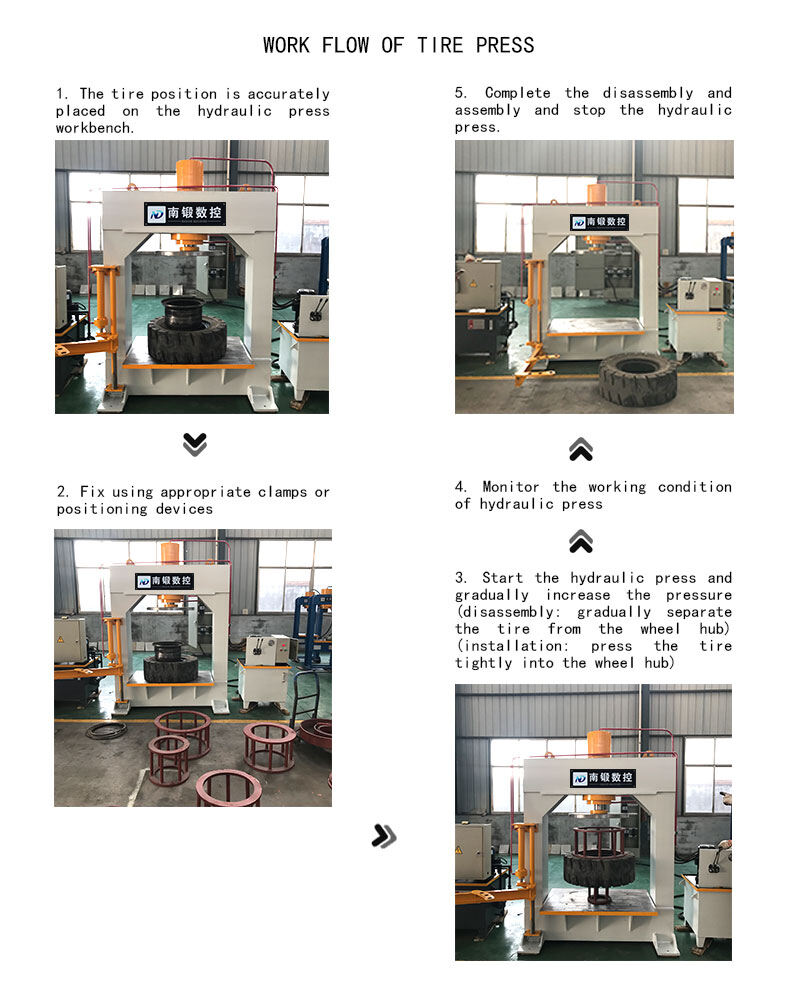

Mesin penekan 120 tan dengan lengan pengangkat hidraulik adalah kelengkapan utama untuk pengeluaran tayar bersaiz sederhana (seperti tayar lori dan tayar kereta penumpang besar) dalam industri pembuatan tayar. Dengan pengintegrasian lengan pengangkat hidraulik, ia boleh merealisasikan pemuatan automatik embrio tayar, penyelesaian pusat acuan secara automatik serta pengeluaran automatik tayar yang telah siap, meningkatkan kecekapan pengeluaran dan keselamatan operasi secara ketara.

| Tonase | Tekanan Operasi | Diameter Silinder/Diameter Rod | Saiz jadual berkesan | Ketinggian pembukaan | Jarak tempuh | Kelajuan penekanan | Kelajuan balik | Kuasa Motor | Spesifikasi Pam Minyak |

|---|---|---|---|---|---|---|---|---|---|

| 100 | 31.5 | D200/d100 | 1000x800 | 1100 | 500 | 7mm/s | 10mm/s | 5.5kw | 10McY (tetap) |

| 120 | 31.5 | D220/d110 | 1000x800 | 1100 | 600 | 6mm/s | 8mm/s | 5.5kw | 10McY (tetap) |

| 160 | 31.5 | D250/d150 | 1400x800 | 1100 | 600 | 6-12mm/s | 15mm/s | 5.5kw | 25McY (tetap) |

| 200 | 31.5 | D290/d160 | 1500x800 | 1200 | 600 | 4-9mm/s | 12mm/s | 5.5kw | 25McY (tetap) |

| 250 | 31.5 | D310/d180 | 1500x800 | 1200 | 600 | 6-12mm/s | 15mm/s | 7.5KW | 40McY (tetap) |

| 300 | 31.5 | D360/d220 | 1500x800 | 1200 | 600 | 4-9mm/s | 15mm/s | 7.5KW | 40McY (tetap) |

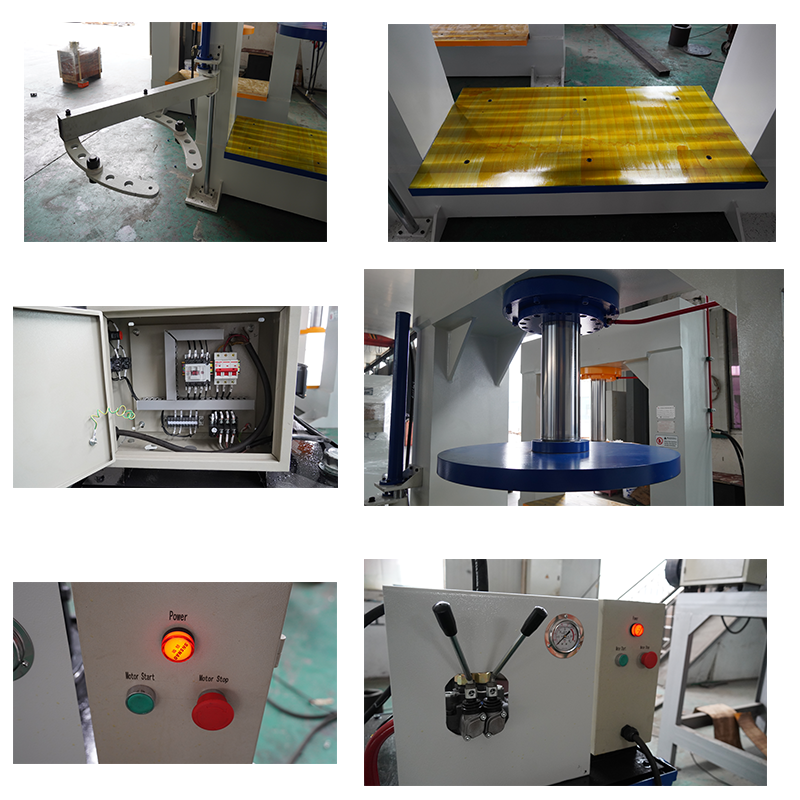

1. Tahap kebolehpercayaan tinggi: - pengangkat dan mesin penekan tayar dihubungkan secara automatik, untuk merealisasikan keseluruhan proses "memasukkan → menekan → mengeluarkan" tanpa campur tangan manusia, meningkatkan kecekapan pengeluaran.

2. Ketepatan penempatan tinggi: lengan pengangkat dilengkapi dengan motor servo + penyulit, dikombinasikan dengan sistem penempatan visual untuk memastikan ralat penjajaran antara tayar mentah dan acuan ≤ ± 1mm.

3. Muatan beban tinggi: silinder lengan pengangkat hidraulik mempunyai muatan ≥ 15 tan (dipadankan dengan mesin penekan tayar 120 tan), mampu membawa tayar mentah/siap seberat 80-100kg dengan mudah

4. Selamat dan boleh dipercayai: lengan pengangkat dilengkapi dengan perlindungan beban lampau (penutupan automatik beban lampau). Had mekanikal (untuk mengelakkan lebihan perjalanan). Reka bentuk redundansi berganda cawan sedut vakum/pencengkam mekanikal (pencengkam bertukar secara automatik apabila cawan sedutan gagal), untuk mengelakkan embrio tayar jatuh.

Skenario Aplikasi Utama

Logistik berat: demontaj harian tayar pejal untuk forklift dan kenderaan forklift, masa demontaj setiap tayar dikurangkan kepada 3-5 minit.

Penyelenggaraan jentera pembinaan: penyelenggaraan tayar untuk peralatan besar seperti jentera penggelek, muatkan, dan lain-lain. Lengan pengangkat mampu membawa tayar yang sangat berat, mengurangkan keperluan bantuan forklift.

Bengkel tayar ulang: pemprosesan secara puket tayar pejal terpakai, mesin pres tayar memisahkan tubuh tayar daripada rim, dan lengan pengangkat membantu proses pengendalian, dengan kapasiti pengendalian harian sebanyak 50-80 tayar.

Kami menawarkan perkhidmatan selepas jualan yang menyeluruh, termasuk pemasangan, pengecaman dan latihan operasi; menyediakan manual pengguna mesin tekan untuk memudahkan pengguna mempelajari cara mengendali dan menyelenggara mesin tekan.

Kami menyediakan set penuh peralatan mesin hidraulik dengan pelbagai penyelesaian reka bentuk yang matang dan kes-kes pelanggan yang berjaya. Kami juga menawarkan perkhidmatan tempahan bersama alat pengacuan dan peralatan talian pengeluaran berkaitan, memberikan perkhidmatan satu henti kepada pelanggan. Anda dialu-alukan untuk menghubungi kami bagi mendapatkan khidmat nasihat.

Pasukan ramah kami ingin mendengar dari anda!

Hak Cipta © Nadun Machinery Manufacture Co., Ltd. Semua Hak Dilindungi - Dasar Privasi