|

Tempat Asal: |

Tengzhou China |

|

Nama Brand: |

Nadun |

|

Nombor Model: |

YQ32-315T |

|

Penyeliaan: |

CE ISO |

|

Kuantiti Pesanan Minimum: |

1 |

|

Butir-butir Pemakanan: |

Contoh termasuk tekanan hidraulik dan cetakan. Sila hubungi kami untuk maklumat lanjut. |

|

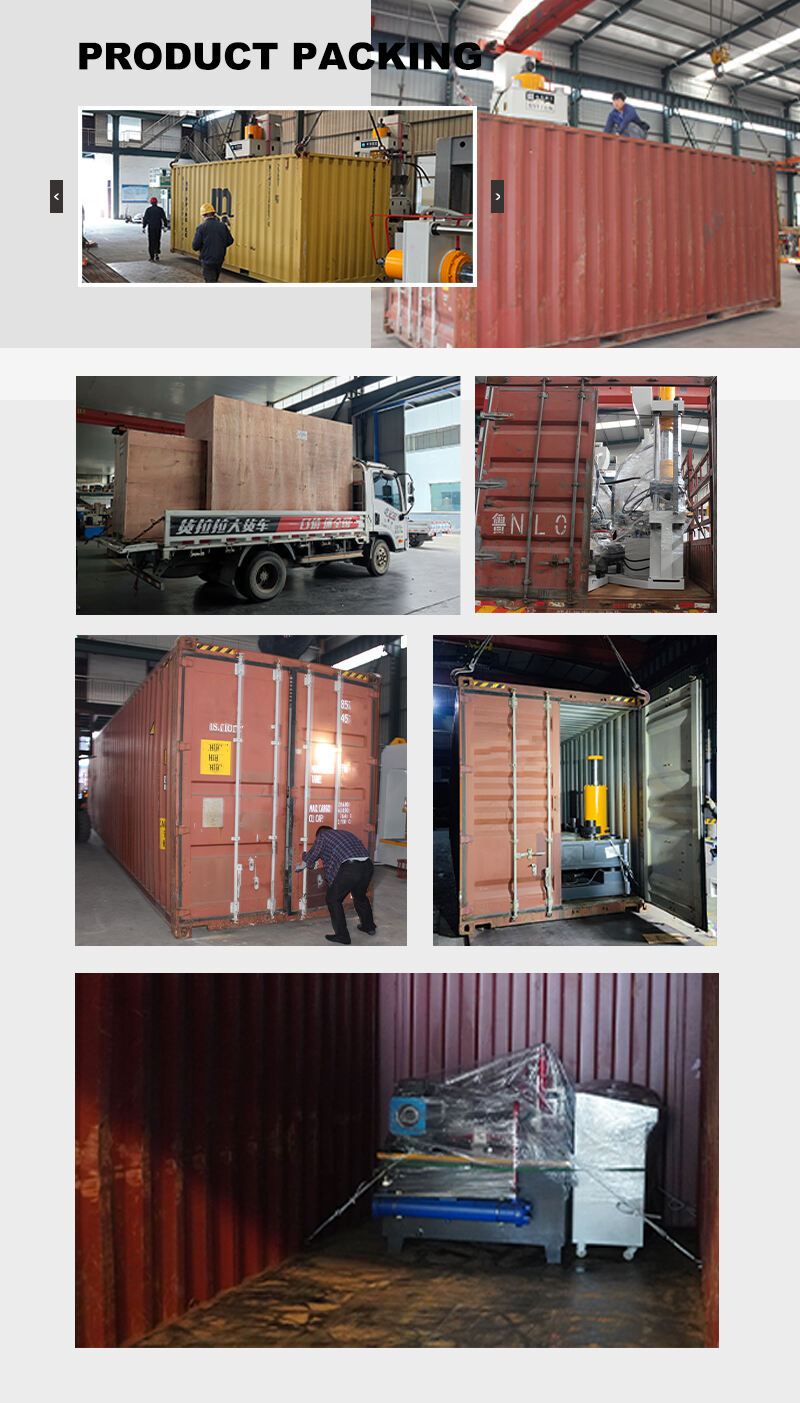

Masa Penghantaran: |

15-45 hari |

|

Syarat Pembayaran: |

L/C D/P D/A T/T |

|

Kemampuan Bekalan: |

50set/m |

mesin tekanan panas 315 tan adalah sejenis peralatan pengacuan tekanan panas dengan tekanan berkadaran 315 tan, yang digunakan untuk membentuk produk plastik dan komposit lainnya. Pertama-tama, bahan mentah plastik dileburkan melalui pengeluar, kemudian leburan plastik dimasukkan ke dalam acuan untuk ditekan, dan pengacuan bahan komposit disiapkan di bawah tekanan tinggi dan suhu sederhana tinggi. Fungsi utamanya adalah untuk memberikan tekanan tinggi melalui sistem hidraulik atau mekanikal serta dikombinasikan dengan pemanasan supaya bahan (seperti plastik, getah, bahan komposit, kayu, serbuk logam, dan sebagainya) mengalami perubahan bentuk plastik atau tindak balas pemapanan, dan akhirnya dihasilkan menjadi produk berbentuk tertentu.

Rangka tiga rasuk dan empat tiang: terdiri daripada rasuk atas, rasuk bawah, peluncur dan empat tiang, mempunyai kekakuan struktur yang tinggi serta rintangan terhadap penghanyutan.

Sesuai untuk proses penekanan berkeupayaan tinggi dan beban tinggi bagi memastikan kestabilan saiz pembentukan bekas plastik besar.

Sistem hidraulik terkamir injap kartrij: mengurangkan sambungan paip, mengurangi risiko kebocoran, tindak balas sistem yang cepat.

Kejutan hidraulik yang kecil, memperpanjang jangka hayat kelengkapan dan kos penyelenggaraan yang rendah.

Sistem kawalan elektrik berasingan: menggunakan pengawal atur cara PLC, menyokong mod operasi manual, separuh automatik dan automatik.

Dilengkapi dengan fungsi pembentukan julat tetap dan tekanan tetap, pengekalan tekanan dengan kelengahan, berhenti kecemasan dan lain-lain, operasi adalah selamat dan fleksibel.

Reka bentuk mesra pengguna: panel operasi disusun secara berkumpulan dan butang mempunyai tanda yang jelas, memudahkan pekerja memulakan kerja dengan cepat.

Parameter seperti langkah peluncur dan kelajuan mampatan boleh dilaraskan mengikut keperluan proses, sesuai untuk pengeluaran pelbagai spesies.

1.Pemprosesan Plastik

Lembaran/papan cetakan: papan PVC keras ditekan, papan bergelombang PE/PP, papan akrilikik, dsb;

Produk bercetak: bahagian dalaman automotif (panel instrumen, panel pintu), kes plastik industri (seperti lapisan tangki rintang kakisan), palet plastik besar, dsb.

2. Getah dan elastomer

Pemvulkanan produk getah: lapisan kord tayar, jalur getah penutup, penyerap hentakan getah;

Bahagian industri getah: penggelek getah besar (untuk mesin cetak, penggelek), penutup getah.

3. Bahan komposit

Laminasi/bahagian bercetak: plastik diperkuat kaca, plastik diperkuat gentian karbon, papan serat aramid;

Cetakan resin termoset: komposit berbasis resin epoksi.

4. Logam serbuk dan seramik

Menekan serbuk logam: pemotong karbida, gear logam serbuk berbasis besi/berbasis kuprum;

Pembentukan bahan barisan seramik: substrat seramik elektronik, komponen struktur seramik presisi.

5. Pemprosesan kayu

Pengeluaran papan buatan: papan ketumpatan, papan serpih;

Kayu terbina semula/kayu bersepadu: sambungan dan penekanan panel kayu pejal bersaiz besar.

Kami menawarkan perkhidmatan selepas jualan yang menyeluruh, termasuk pemasangan, pengecaman dan latihan operasi; menyediakan manual pengguna mesin tekan untuk memudahkan pengguna mempelajari cara mengendali dan menyelenggara mesin tekan.

Kami menyediakan set penuh peralatan mesin hidraulik dengan pelbagai penyelesaian reka bentuk yang matang dan kes-kes pelanggan yang berjaya. Kami juga menawarkan perkhidmatan tempahan bersama alat pengacuan dan peralatan talian pengeluaran berkaitan, memberikan perkhidmatan satu henti kepada pelanggan. Anda dialu-alukan untuk menghubungi kami bagi mendapatkan khidmat nasihat.

Pasukan ramah kami ingin mendengar dari anda!

Hak Cipta © Nadun Machinery Manufacture Co., Ltd. Semua Hak Dilindungi - Dasar Privasi