|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

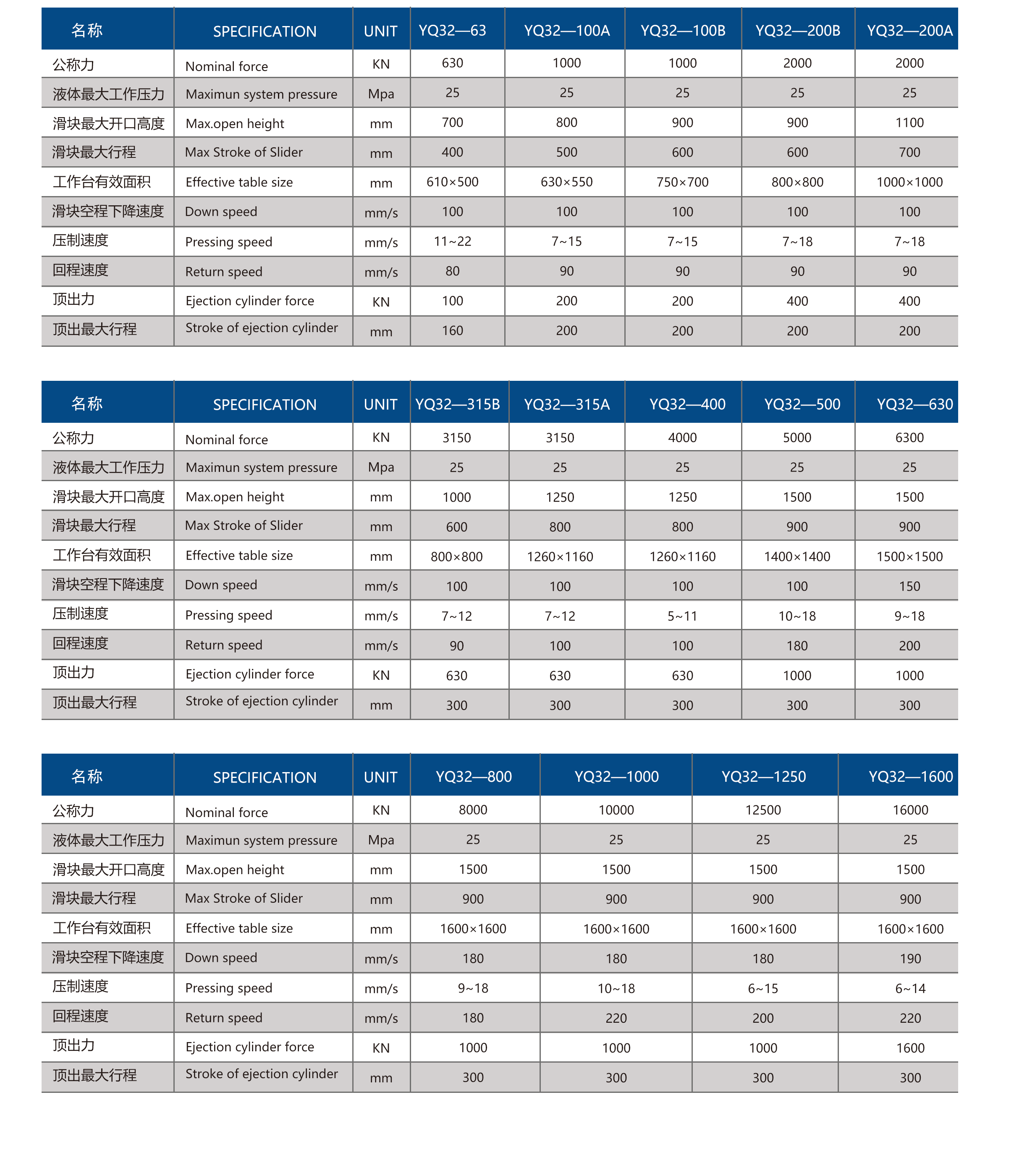

Model Number: |

YQ32-315T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

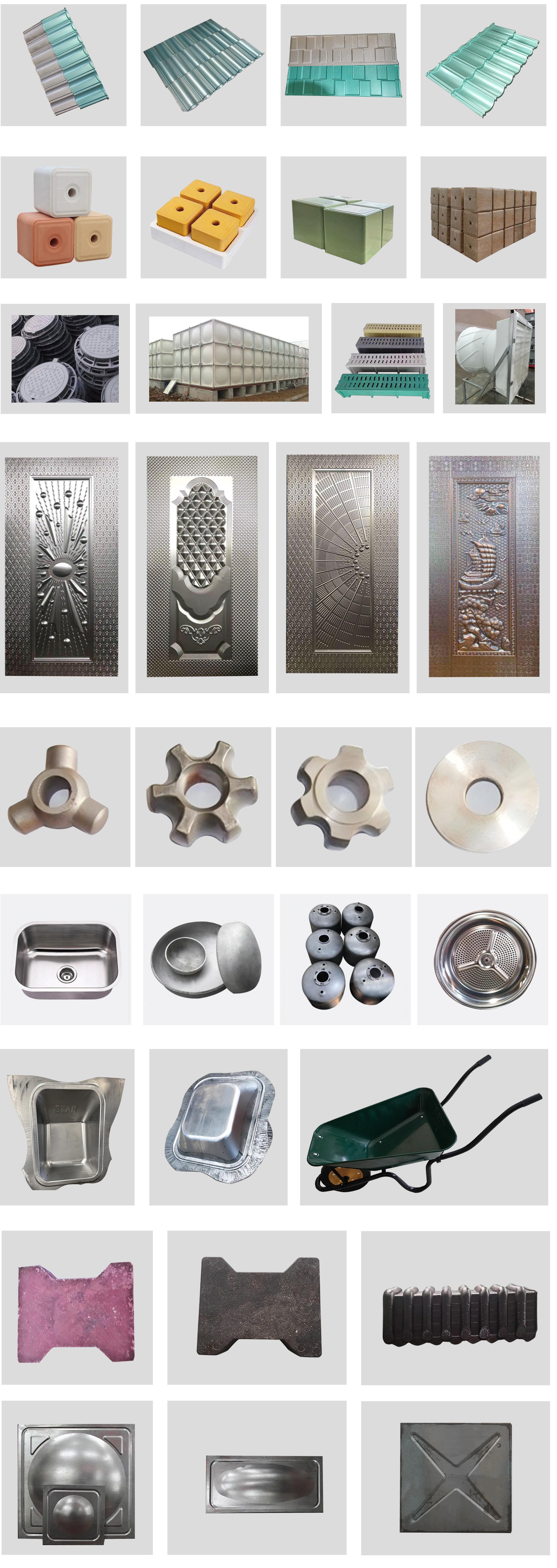

Metal hot press is a special molding equipment designed for the thermoplastic characteristics of metal materials, the core principle is to heat the metal billet to above the recrystallization temperature, so that it is softened and has good plasticity, and then through the hydraulic system to apply high pressure, so that the material in the mold cavity plastic deformation, and ultimately to obtain the required shape, size and performance of the metal products.

High-temperature adaptability: the machine body and molds are made of high-temperature-resistant materials, and the heating system ensures that the blanks are heated uniformly to avoid local overheating or underheating;

High-precision molding: precise control of pressure, temperature and stroke is realized through PLC control system, and the repeatability of the master cylinder position can reach ±0.02mm, which ensures the consistency of product size;

High-efficiency production: fast downstream cylinder shortens the empty stroke time, convenient switching of fixed pressure/fixed stroke mode, with automatic feeding system, the production efficiency is more than 200% higher than that of traditional equipment;

Diversified processes: support hot forging, hot pressing, hot calibration, hot press fitting and other processes, applicable to the production of metal parts of different shapes and sizes.

Precision forgings production: for key components in the automotive and aerospace fields, such as gear blanks, engine crankshafts, bearing rings, aircraft engine blades, etc., the

Large metal parts molding: used in the field of construction machinery, marine field of counterweight block car chassis parts, large box, etc., to solve the traditional process can not be molded;

Metal powder molding: used for magnetic materials, powder metallurgy products pressing, through hot pressing to improve product density and mechanical properties;

Thermal correction and press fitting: used for deformation correction of metal structural parts, bearing and shaft interference fit press fitting, soften the material by heating, reduce the difficulty of assembly

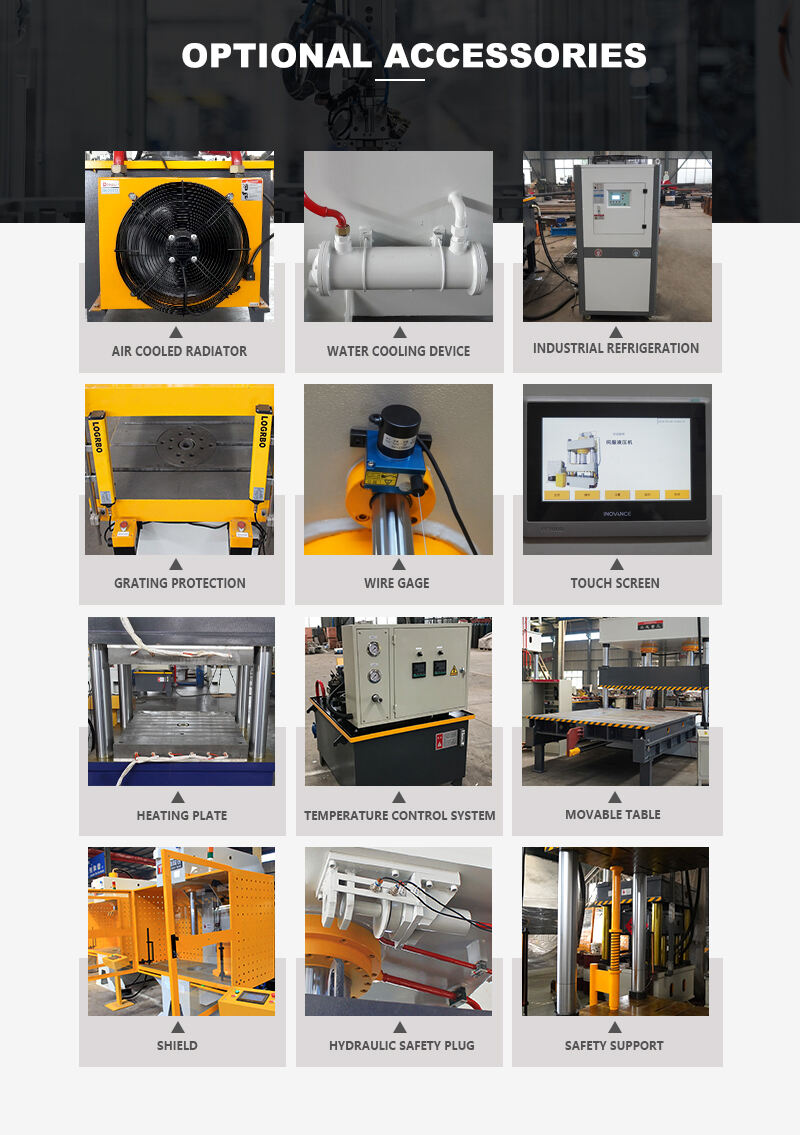

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy