|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

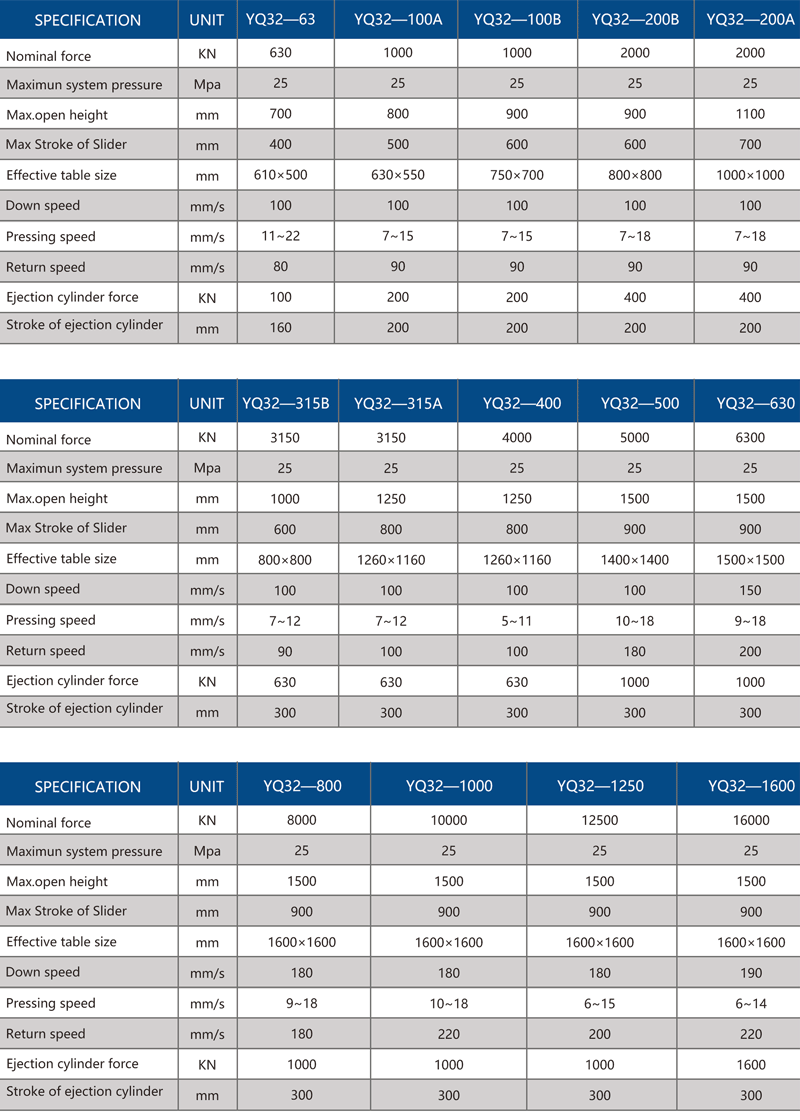

Model Number: |

YQ32-1500T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

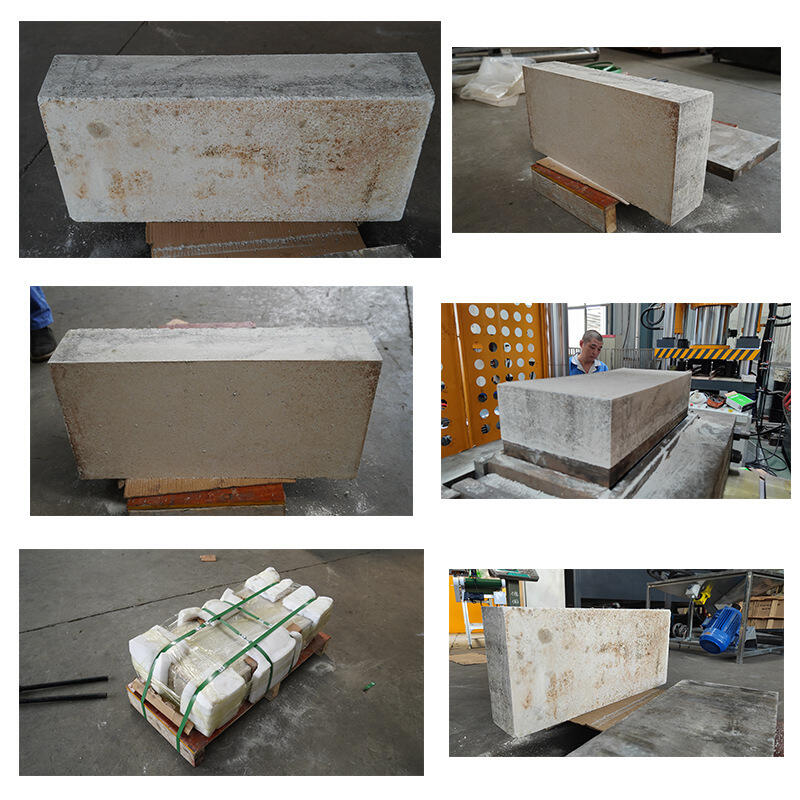

This is a high-tonnage, high-efficiency forming machine specifically designed for producing refractory materials such as firebricks, high-alumina bricks, magnesia bricks, and clay bricks. By employing high-pressure molding, it ensures the green bricks achieve high density, high strength, and high precision, making it the core production equipment for modern refractory plants.

High Pressure: 1,500 tons of pressure delivers high-density, high-quality refractory bricks that meet demanding industrial furnace requirements.

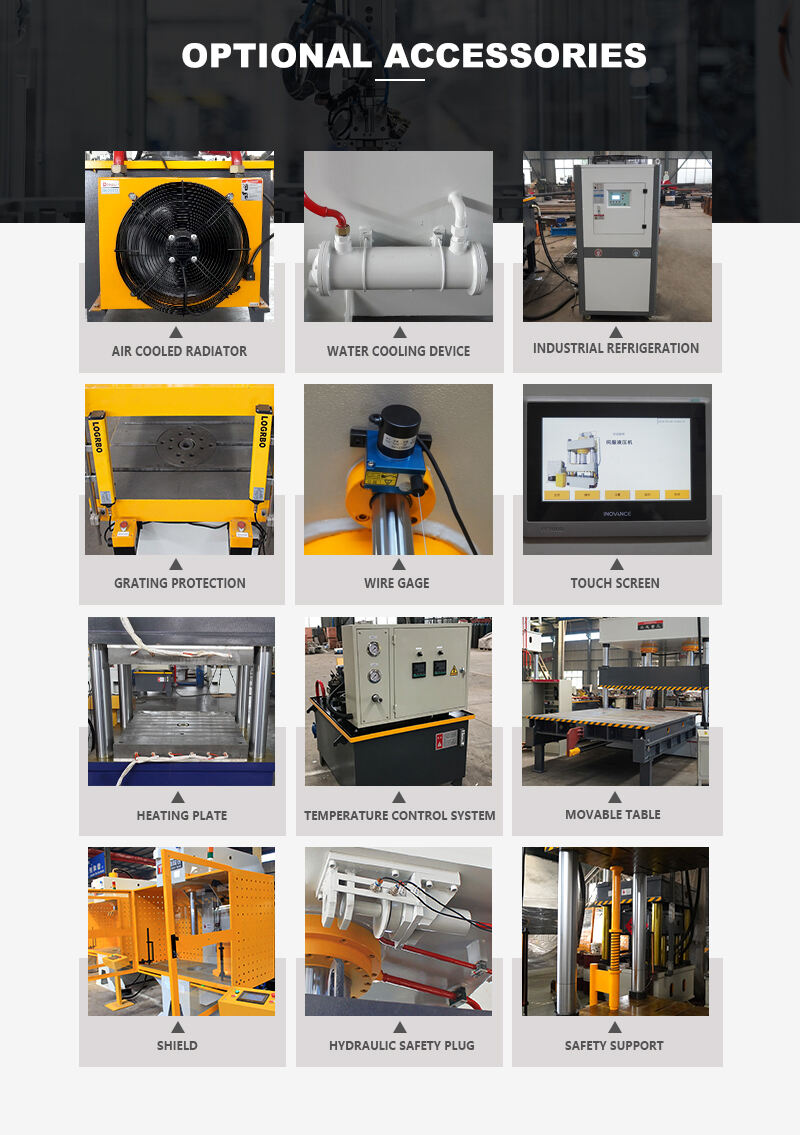

High Precision: Hydraulic and electronic control systems ensure precise control over pressing force, positioning, and holding time, resulting in consistent product dimensions and low scrap rates.

High Efficiency: High automation and short cycle times deliver production efficiency far surpassing older equipment like friction presses.

Energy-Efficient and Eco-Friendly: Variable pump systems supply oil on demand, achieving significant energy savings over legacy equipment. Low noise levels create a better working environment.

Easy Operation: Touchscreen controls offer intuitive parameter settings, with self-diagnostic capabilities for simplified maintenance.

Refractory Materials: Pressed high-density refractory bricks for lining steel, glass, and cement kilns, enhancing resistance to erosion in high-temperature environments.

Industrial Applications: Extensively utilized in rail transit (high-speed rail car crossbeams, end beams), automotive manufacturing (battery pack trays, subframes), architectural steel structures (H-beam leveling, curtain wall joints), wind/nuclear power (tower flanges, base forging components), and composite materials (SMC automotive roof panels, carbon fiber bulkheads), meeting forming demands for large-scale, high-strength structural components.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy