Nadun Machinery Manufacture Co., Ltd.

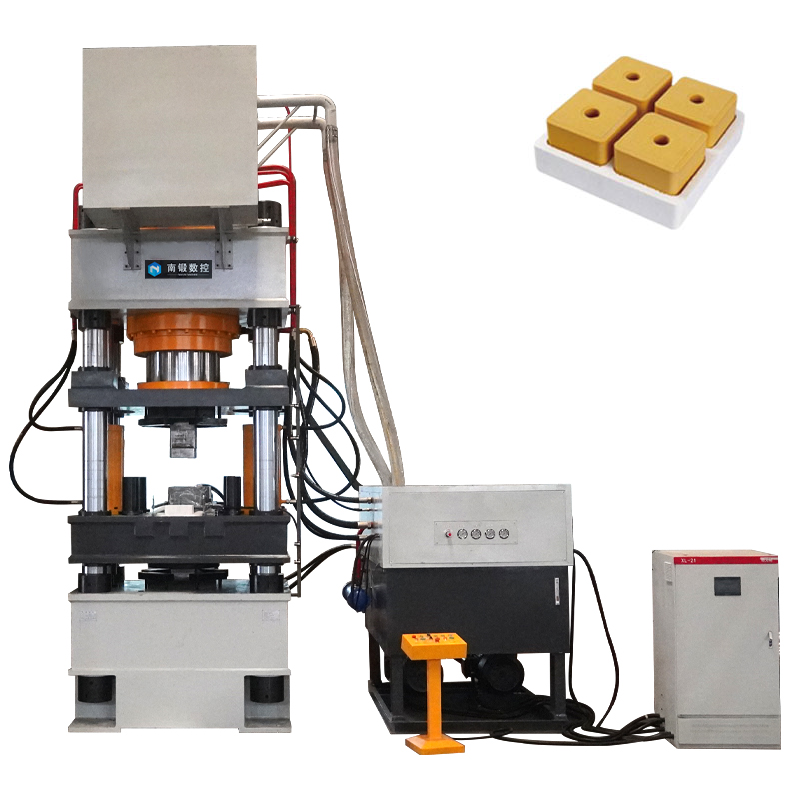

mașină de presare a formelor

Dacă vrei să produci multe articole similare mai repede, o presă de modelare pentru cauciuc este un instrument foarte util! Indiferent ce găsești, toate sunt compuse din aceste mașini magice, cum ar fi sticlele de plastic, piesele auto sau ceva care le aduce bucurie copiilor. În acest text, vom acoperi cum funcționează aceste mașini, ce pot face și de ce sunt extrem de importante pentru orice afacere.

Când produci în masă același articol, este esențial ca toate să arate identice. Iar aceasta este exact misiunea mașinilor de presare cu forme! Ele fac acest lucru prin utilizarea materialelor precum plasticul sau metalul și le presă într-o formă folosind un instrument special. O formă este cam ca un decuplitor de biscurți, doar că nu decupează forma... ci doar oprimă materialul în acea formă.

Opțiuni versatilo și personalizabile de modelare cu mașini pres modern

Este un mod rapid și eficient de a face multe numere odată, prin intermediul unei mașini de presare cu formă. Acest lucru poate fi în special util pentru afacerile care au o cerere mare, având nevoie ca fiecare produs să fie creat cât mai repede posibil. Deoarece aceste mașini sunt în esență programate pe computer, vor produce aceeași copie a unui produs de fiecare dată, așa că poți fi la 100% sigur că toate articolele fabricate vor arăta exact la fel. Clienții au nevoie de asta pentru că doresc cel mai bun produs.

S-au terminat zilele când trebuia să lucrezi cu forme care au fost deja create — una dintre lucrurile pe care ne plac despre mașinile moderne de presare cu formă este că poți personaliza formele astfel încât să facă exact ceea ce ai nevoie. De exemplu, dacă dorești să proiectezi ceva mai mare sau mai mic, o mica schimbare de formă și apoi există flexibilitatea de a crea o formă nouă sau de a munci pe una existentă. Cu această abordare, se permite afacerilor să satisfacă mai bine nevoile clienților lor.

-

Precizie și consecvență în modelare cu o mașină pres hidraulic

Acest tip de presă hidraulică este util atunci când trebuie să modelați materiale mai dure, de exemplu, metal. O forță mai mare înseamnă că poate lucra cu materiale mai rezistente și este mai ușor de folosit pe termen lung. Mai mult, mașinile de presare hidraulică sunt excelente în ceea ce privește precizia și pot crea piese cu detaliu mai fin, care ar fi extrem de dificil de realizat manual. Acest lucru înseamnă că produciți un produs premium care este unic.

-

Economisiți timp și reduceți deșeurile cu o mașină pres automată pentru modelare

Economisește timp și resurse: Dacă începeți să utilizați o mașină de presare a formelor automate, aceasta vă va ajuta să economisiți timp. Ele sunt muncitori pe care le puteți configura și apoi le-ați trebui doar să le mențineți, fără să fie nevoie să le operați ca un loc de muncă zilnic. Deoarece o mașină este mult mai precisă, nu veți trebui să corectați unele dintre erorile mai puțin evidente care pot strica materialul dinamic și lucrarea. Astfel, veți putea produce mai multe produse, mai repede și cu mai puțină grabă!

-

Creșteți producția cu o mașină pres modelatoare fiabilă și durabilă

Găsirea unei presuri de modelare de încredere și durabilă poate să-ți permită să crești ratele de producție, lăsându-te să produci mai multe articole în mai puțin timp. Sper că aceste mașini nu vor decide niciodată să te abandoneze. Având în vedere că aceste lucruri nu erau ieftine la momentul lansării (și majoritatea dintre ele sunt încă scumpe astăzi), au fost construite pentru a dura și a funcționa; sper că testele vor să demonstreze acest lucru! Acest lucru este crucial pentru afaceri, care necesită procesarea rapidă a comandelor clienților.

Why choose Nadun mașină de presare a formelor?

-

Calitate și Performanță Excepțională:

Produsele Nadun Machinery sunt cunoscute pentru calitatea lor ridicată, performanța excepțională și viața utilă lungă. Echipa de cercetare și proiectare a companiei include mai mult de zece mașini pres modelatoare, fiecare având peste 10 ani de experiență în domeniul cercetării și dezvoltării. Echipa noastră se îmbunătățește și inovă continuu pentru a rămâne în ritm cu cerințele pieței schimbătoare.

-

Experiența companiei și prezența globală:

Nadun Machinery este un producător și exportator de top al echipamentelor pentru prelucrarea metalelor, cu o experiență de peste 17 ani. Ne concentrăm pe prese de perforare și prese hidraulice. De asemenea, oferim mașini de tăiat și mașini de îndoit. Produsele noastre sunt vândute în peste 150 de țări din întreaga lume, iar mașina de presat prin injectare stabilește noi standarde în domeniul fabricării mașinilor.

-

O Varietate de Produse

În domeniul produselor de răcire, mărcile Dragon and Tiger și Temple of Heaven au fost concepute pentru a satisface cererea largă de pe piață, adaptându-se astfel unei varietăți de scenarii de utilizare ale consumatorilor. Mașina de presat prin injectare a companiei a devenit un lider în domeniul sănătății, bazându-se pe dezvoltarea unor linii de produse de marcă, produse pentru sănătate și pe experiența utilizatorului.

-

Calitate fiabilă a produsului

Compania asigură instalarea și punerea în funcțiune a peste 400 de clienți în fiecare an. Fabrică între 500-600 de seturi de produse diferite în fiecare an. Aceste produse au fost certificate de ISO, CE și SGS. Suntem deţinători ai numeroase brevete de inovaţie de produse, certificate onorifice, care arată dedicarea la mașina de presă de modelare.

Categorii de produse conexe

- Presă de modelare pentru cauciuc

- Pres hidraulic pentru modelarea cauciucului

- Presă hidraulică

- Mășina de tăiere a metalului

- Mașină hidraulică de tăiere a metalului

- Presă hidraulică c

- Mașinărie de tăiere a foii metalice

- Mășina jack press

- Atașament frână presurilor pentru presă hidraulică

- Cel mai puternic hidraulic press

- Controler pentru frână presă

- Mașină pres hidraulic electric

Nu găsiți ceea ce căutați?

Contactați consultanții noștri pentru mai multe produse disponibile.

Solicitați acum o ofertă

Contactați-ne

Drepturi de autor © Nadun Machinery Manufacture Co., Ltd. Toate drepturile rezervate - Politica de confidențialitate

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN