|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

Model Number: |

YQ32-1500T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

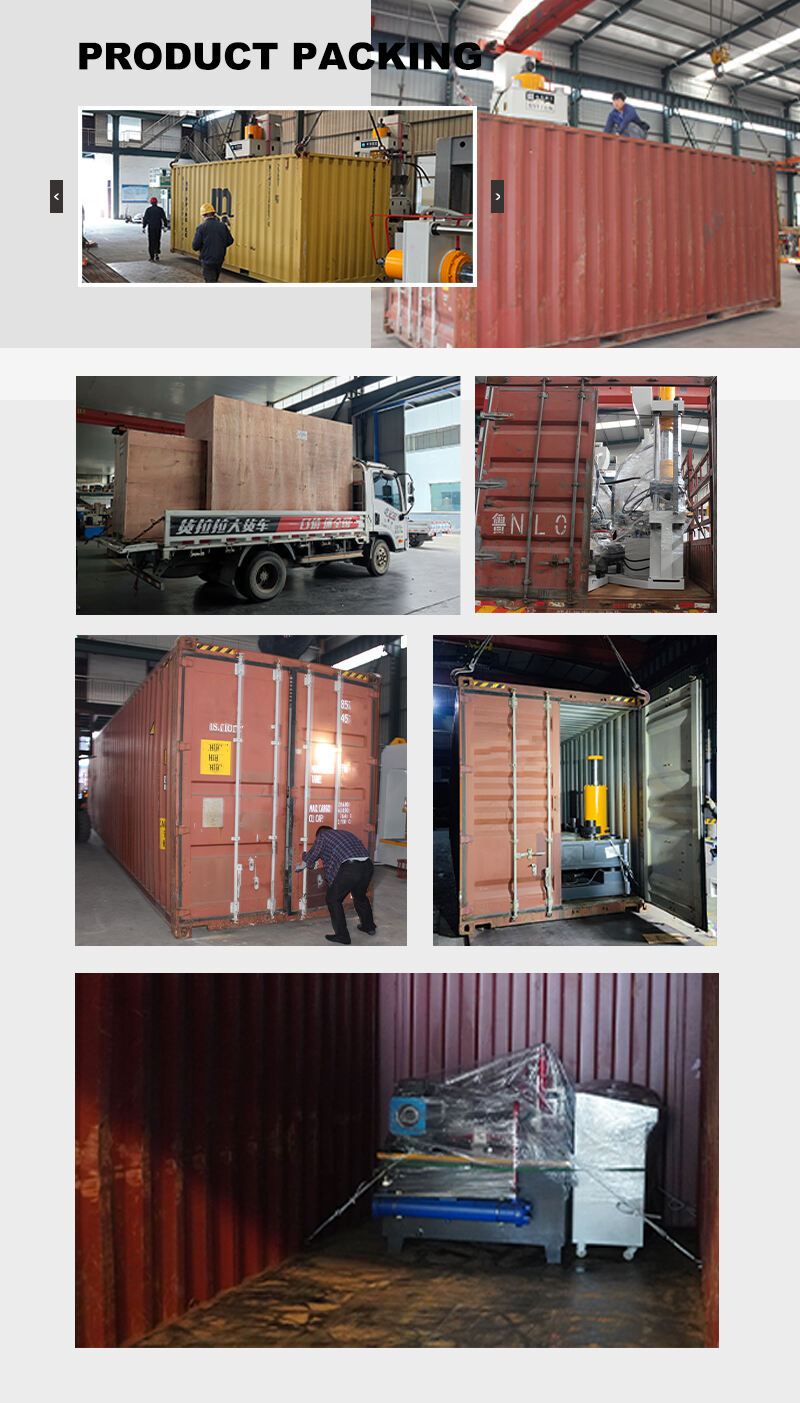

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

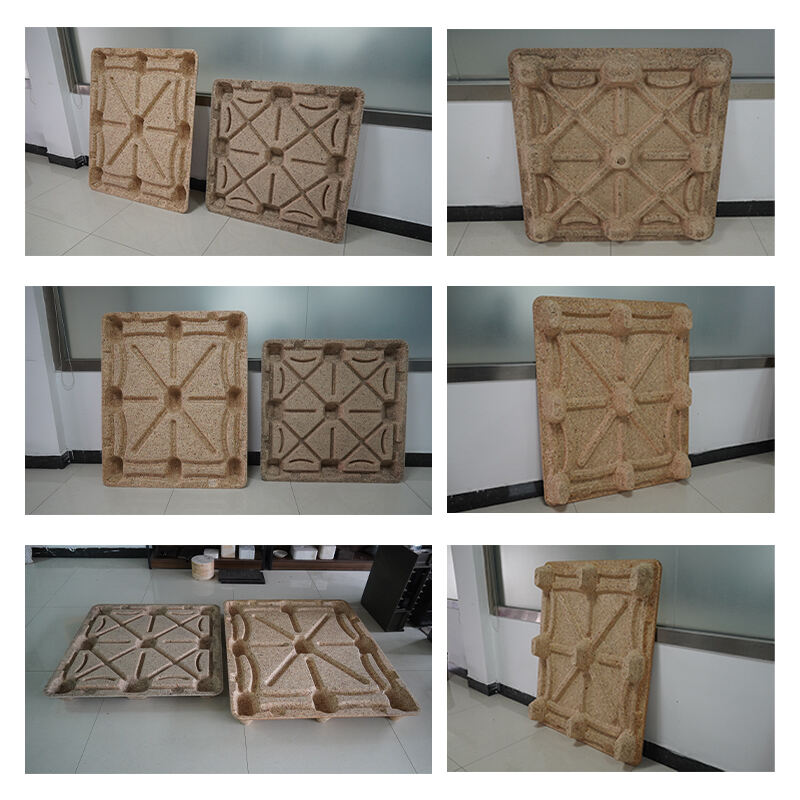

Sawdust pallet hydraulic press (also known as wood chips pallet molding hydraulic press, molded pallet hot press) is a use of hydraulic system pressure, sawdust, straw, waste chemical fibers and other raw materials mixed with binder, through the high temperature and high pressure molding of special equipment

|

YQ32 Technical Parameters |

||||||||

|

|

Unit |

YQ32—63 |

YQ32—100A |

YQ32—100B |

YQ32—200A |

YQ32—200B |

YQ32—315A |

YQ32—315B |

|

Nominal force |

KN |

630 |

1000 |

1000 |

2000 |

2000 |

3150 |

3150 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

700 |

800 |

900 |

900 |

1100 |

1000 |

1250 |

|

Max Stroke of Slider |

mm |

400 |

500 |

600 |

600 |

700 |

600 |

800 |

|

Effective table size |

mm |

610×500 |

630×550 |

750×700 |

800×800 |

1000×1000 |

800×800 |

1260×1160 |

|

Down speed |

mm/s |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Pressing speed |

mm/s |

11~22 |

7~15 |

7~15 |

7~18 |

7~18 |

7~12 |

7~12 |

|

Return speed |

mm/s |

80 |

90 |

90 |

90 |

90 |

90 |

100 |

|

Ejection cylinder force |

KN |

100 |

200 |

200 |

400 |

400 |

630 |

630 |

|

Stroke of ejection cylinder |

mm |

160 |

200 |

200 |

200 |

200 |

300 |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

Unit |

YQ32—400 |

YQ32—500 |

YQ32—630 |

YQ32—800 |

YQ32—1000 |

YQ32—1250 |

YQ32—1600 |

|

Nominal force |

KN |

4000 |

5000 |

6300 |

8000 |

10000 |

12500 |

16000 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

1250 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Max Stroke of Slider |

mm |

800 |

900 |

900 |

900 |

900 |

900 |

900 |

|

Effective table size |

mm |

1260×1160 |

1400×1400 |

1500×1500 |

1600×1600 |

1600×1600 |

1600×1600 |

1600×1600 |

|

Down speed |

mm/s |

100 |

150 |

150 |

180 |

180 |

180 |

190 |

|

Pressing speed |

mm/s |

5~11 |

10~18 |

9~18 |

9~18 |

10~18 |

6~15 |

6~14 |

|

Return speed |

mm/s |

100 |

180 |

200 |

180 |

220 |

200 |

220 |

|

Ejection cylinder force |

KN |

630 |

1000 |

1000 |

1000 |

1000 |

1000 |

1600 |

|

Stroke of ejection cylinder |

mm |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

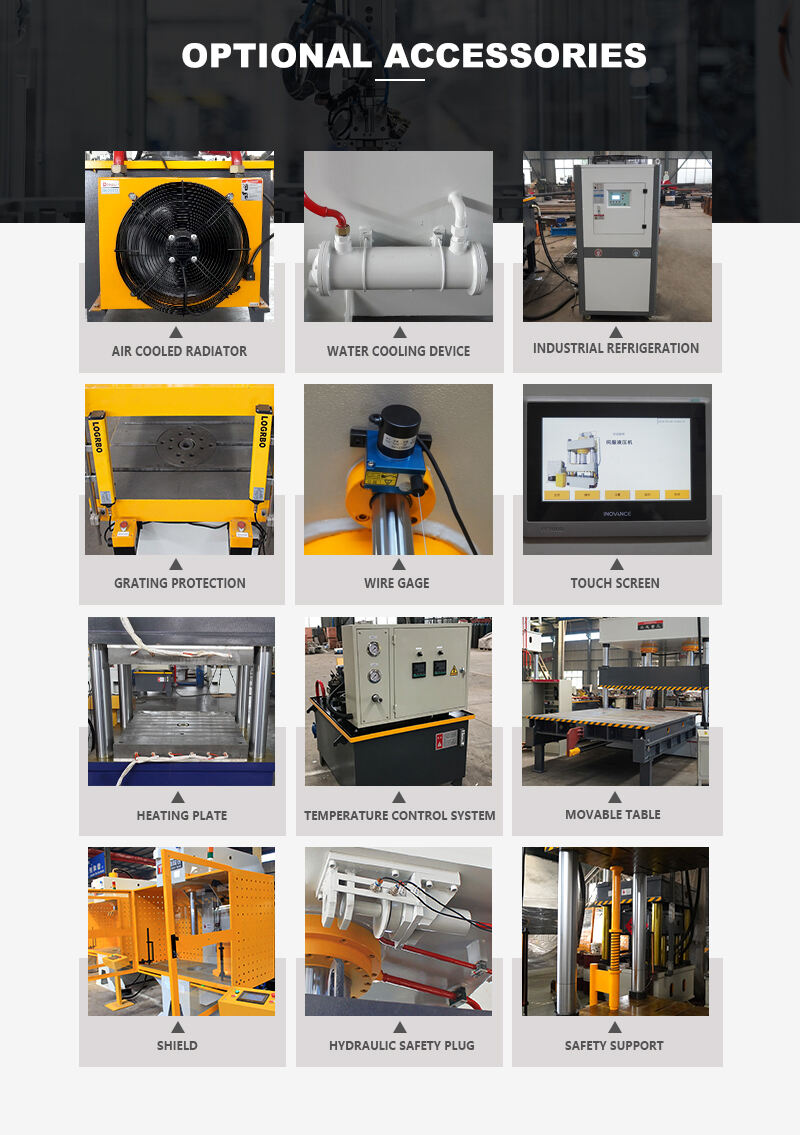

Hydraulic transmission system:

The power source is an oil pump (gear pump, vane pump or piston pump), which transmits the pressure through Pascal's law and drives the ram to complete the pressurizing, holding and un-pressurizing actions.

Typical pressure range: 800 tons to 2,500 tons, pressure up to 25MPa, to ensure that the pallet density up to 900kg/m³ or more.

Hot press molding process:

Raw material pre-treatment: sawdust is crushed to a uniform particle size and dried to a moisture content of 8%-12%.

Mixing and stirring: add glue (such as urea-formaldehyde resin, phenol-formaldehyde resin) according to the proportion and mix thoroughly.

Molding: Fill the mold with the mixture, pressurize the hydraulic system to the designed tonnage, meanwhile the heating system (steam or heat-conducting oil) warms up to 150-200℃, and hold the pressure to cure for 400-600 seconds.

Cooling: After molding, the pallet is cooled and demolded, and the edges and corners are sanded and processed.

1.Logistics storage pallet

Products: standard pallet, grid pallet (breathable), paper pallet (environmentally friendly, disposable);

2. Industrial packaging pallets

Products: packing box pallets (for mechanical parts, electronic components transportation), heavy duty pallets;

3. agriculture and food pallets

Products: agricultural packaging pallets (e.g., vegetables, fruits transportation), food-grade pallets (need food-grade adhesive, such as starch-based adhesive);

4. Environmentally friendly recycled pallets

Products: Recycled wood chip pallets (utilizing waste wood chips), biodegradable pallets (adding bio-based adhesives);

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy