|

Härstammar från: |

Tengzhou Kina |

|

Varumärke: |

Nadun |

|

Modellnummer: |

YQ32-500T |

|

Certifiering: |

CE ISO |

|

Minsta beställningskvantitet: |

1 |

|

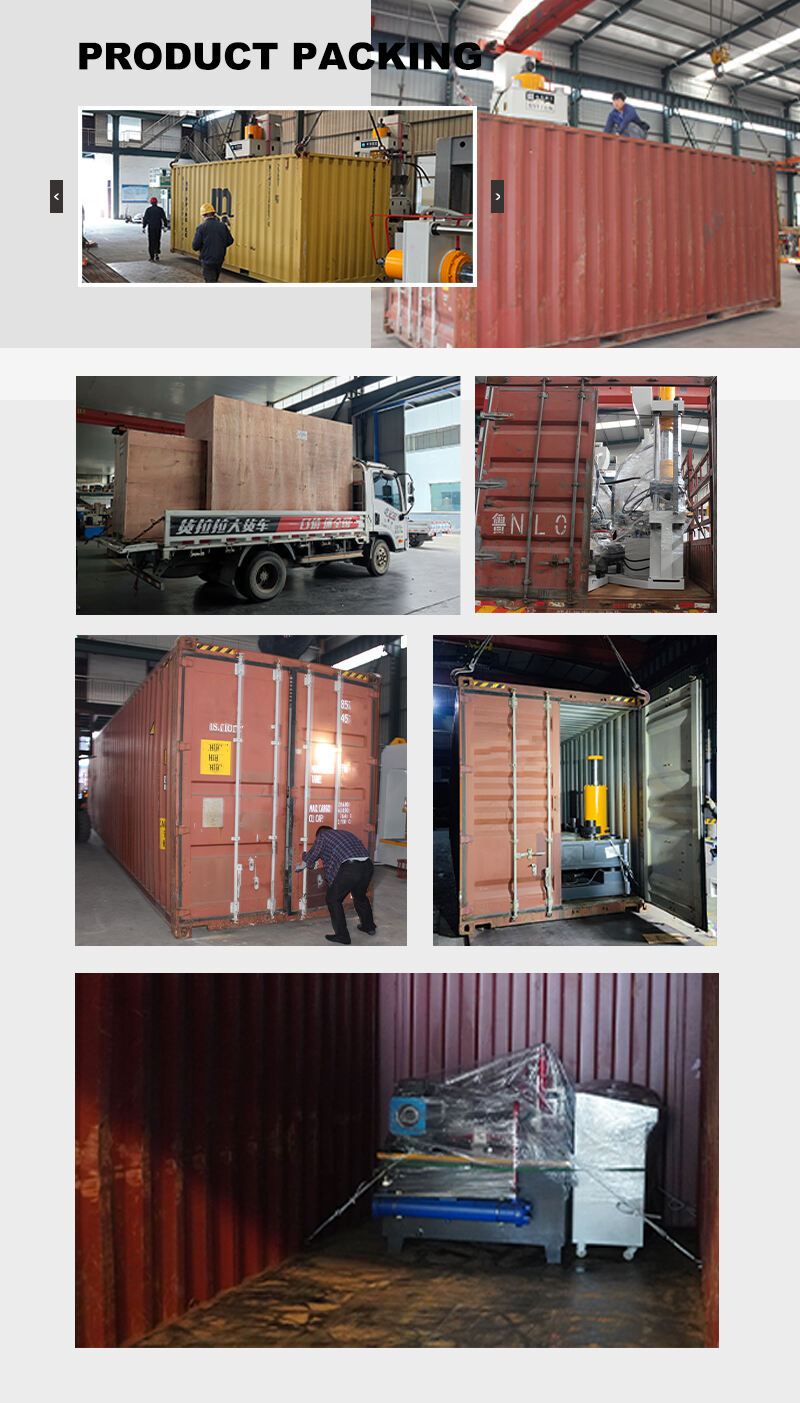

Förpackningsinformation: |

Exemplet omfattar en hydraulisk tryckmaskin och form. Kontakta oss för mer information. |

|

Leveranstid: |

15-45 dagar |

|

Betalningsvillkor: |

L/C D/P D/A T/T |

|

Leveransförmåga: |

50st/m |

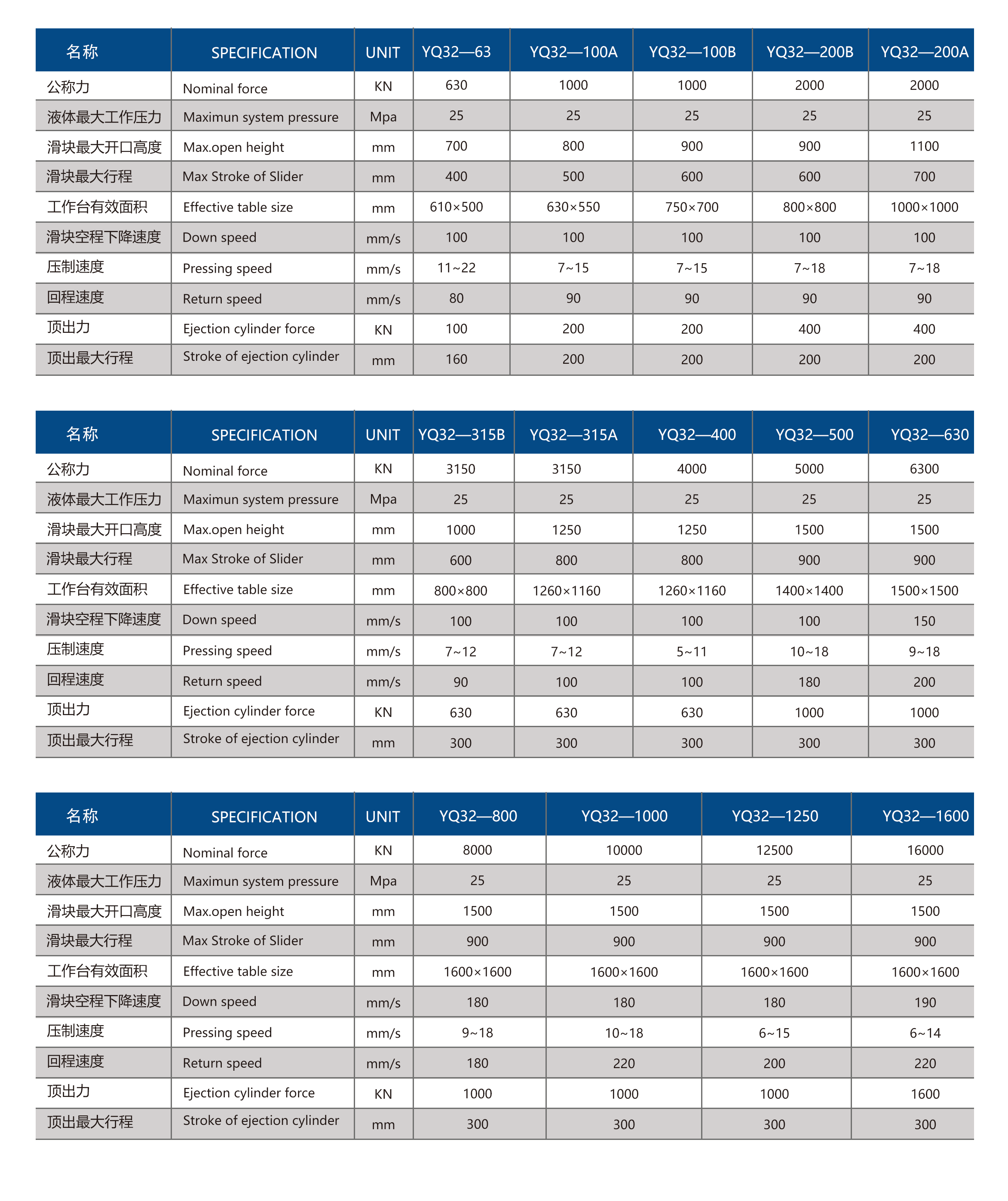

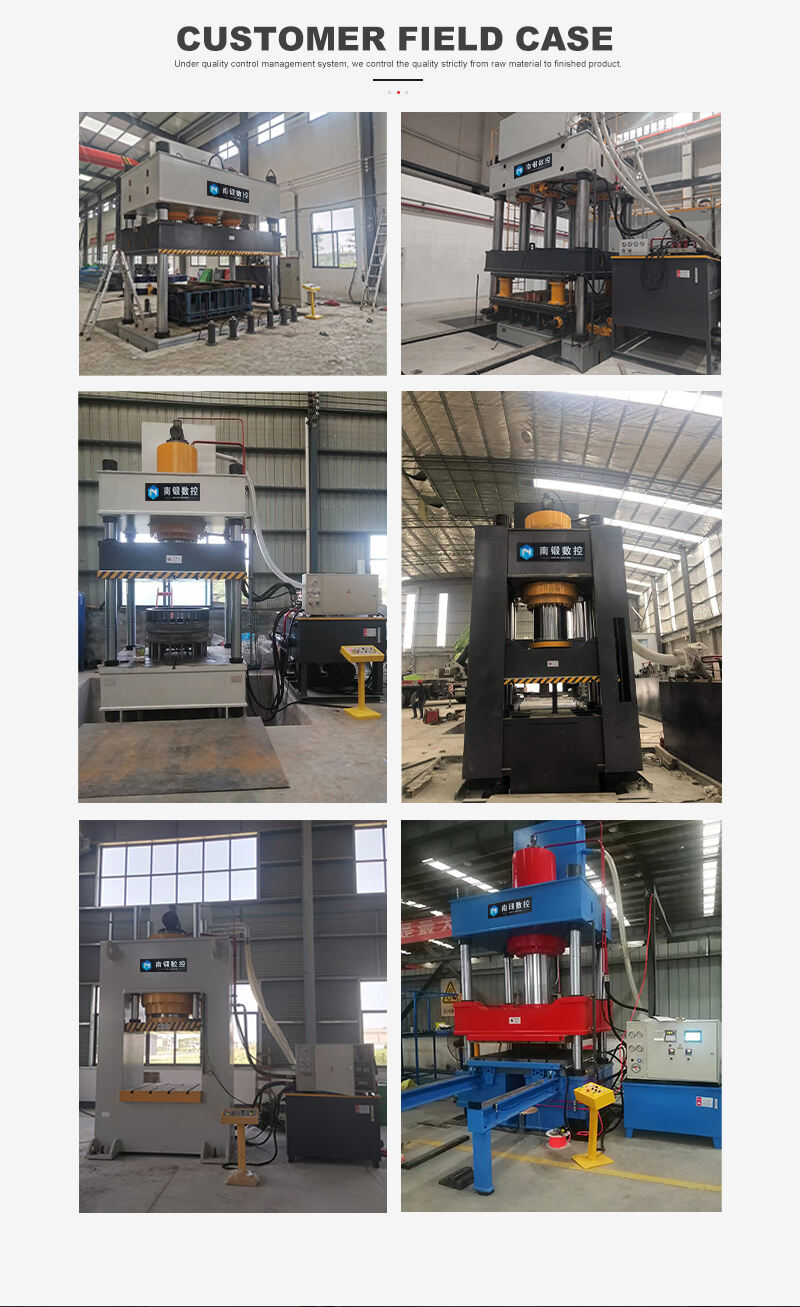

500 tons trebalks fyrväggscylindern (med galler, luftkyld) är en typ av hydraulisk utrustning som integrerar funktionerna formning, dragning och pressning, vilket är lämpligt för processer som plåtdragning, smittning och pulverkomprimering. Gallerbeskydd och vattenkylningsystem kan förbättra driftsäkerheten respektive utrustningsstabiliteten.

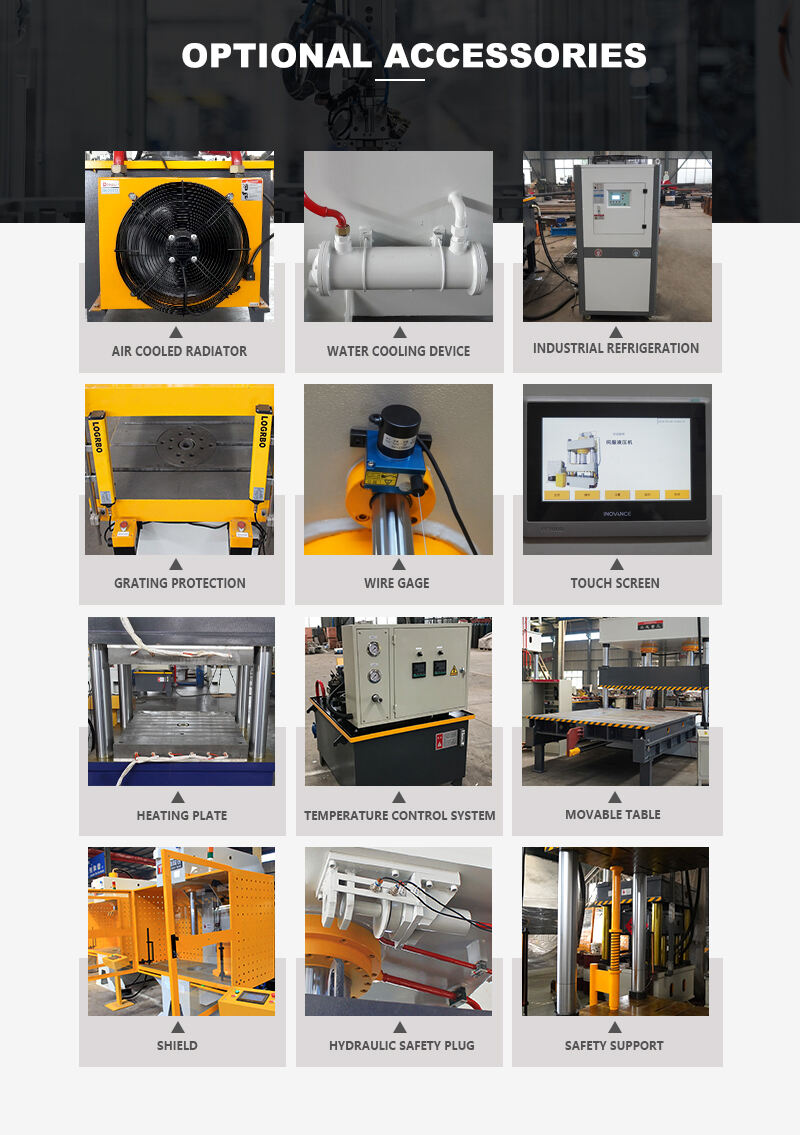

Skyddssystem med ljussperre

Funktion: Genom att sända och motta infraröda eller laserstrålar bildas en säkerhetsljusgardin, systemet aktiverar omedelbart nödstopp när operatören eller ett föremål kommer in i farozonen, vilket förhindrar trytskador.

Fördel: Uppfyller internationella säkerhetsstandarder (t.ex. ISO 13849), förbättrar betydligt driftsäkerheten, särskilt lämplig för scenarier med manuell pålastning och urlastning.

Luftkyla

Funktion: Tvungen cirkulation av luft genom inbyggd fläkt eller extern luftkylning minskar hydrauloljans temperatur, vilket förhindrar att höga oljetemperaturer försämrar systemets prestanda eller skadar komponenter.

Jämförelse med vattenkylning: luftkylning kräver ingen extra vattenledningsinfrastruktur, enklare installation och underhåll, men kyleffekten är något lägre än vattenkylning, lämplig för måttlig omgivningstemperatur eller scenarier med låga kylerkrav.

Tre-balkar fyra pelare-struktur

Stabilitet: övre balken, glidblocket och bordet är sammanbundna av fyra pelare och bildar en sluten ram med stark motståndskraft mot delvis belastning, lämplig för högprecisions formningsprocess.

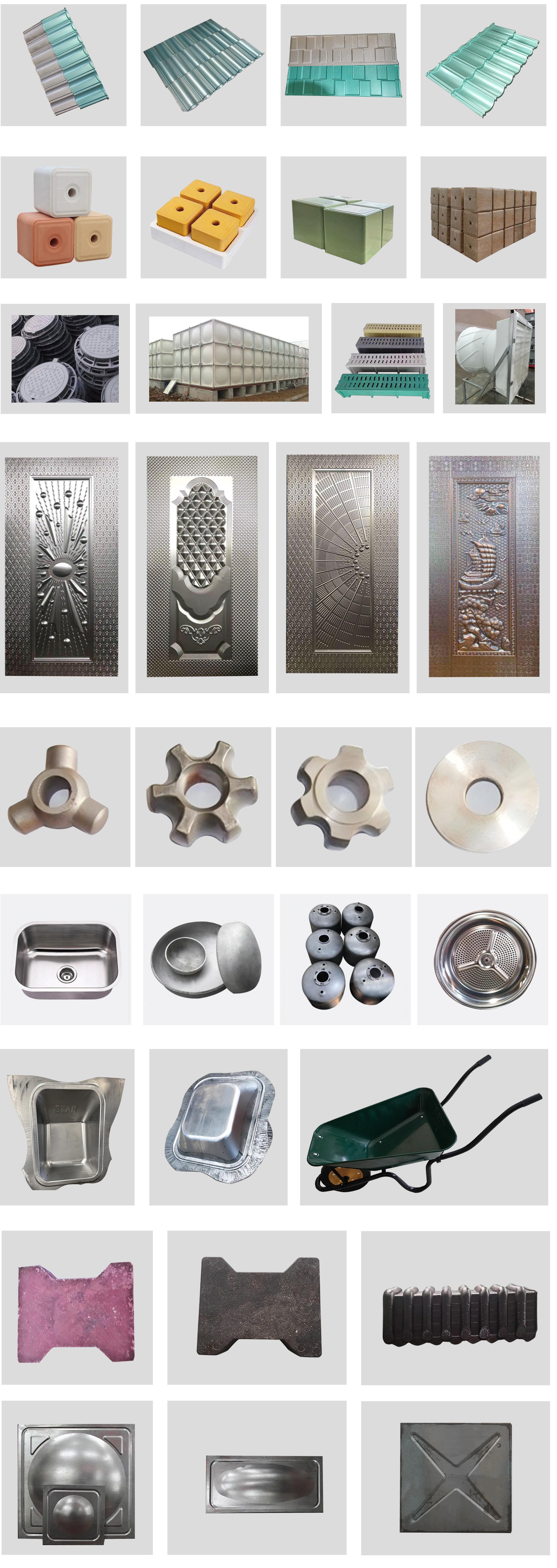

Plåtsträckformning: såsom bilkomponenter, hushållsapparatskal m.m.

Smedeprocesser: såsom vargodsformning och pressformning av metaller som koppar, stål, aluminium, tenn och andra material.

Pulverformning: såsom diverse metallpulver, magnetpulver, keramikpulver, sintermetallprodukter, läkemedel m.fl. komprimeringsformning.

Övriga processer: såsom randformning (flanging), böjning, stansning, kalibrering, pressning m.m.

Vi erbjuder omfattande efterförsäljningstjänster, inklusive installation, kalibrering och driftsträning; vi tillhandahåller tryckmaskinshandböcker för att underlätta användarlärande om hur man bedriver och underhåller tryckmaskinen.

Vi erbjuder en komplett uppsättning hydrauliska pressutrustning med många mogna designlösningar och framgångsrika kundfall. Vi erbjuder också anpassad service med formverktyg och motsvarande produktionslinjeutrustning, och tillhandahåller en-stop-service för våra kunder. Välkommen att ringa oss för mer information.

Vårt vänliga team vill gärna höra från dig!

Upphovsrätt © Nadun Machinery Manufacture Co., Ltd. Alla rättigheter förbehålls - Integritetspolicy