|

تولید کا مقام: |

تینگژو چین |

|

برانڈ نام: |

نادون |

|

مودل نمبر: |

YQ32-1000T |

|

معیاریشن: |

CE ISO |

|

کم ترین آرڈر کیتی: |

1 |

|

پیکنگ تفصیلات: |

نمونہ میں ہائیڈرولیک پریس اور مالد شامل ہیں۔ مزید تفصیلات کے لئے ہم سے رابطہ کریں۔ |

|

دلوں وقت: |

15-45 دن |

|

پیمانہ تعلقات: |

L/C D/P D/A T/T |

|

فراہم کرنے کی صلاحیت: |

50set/m |

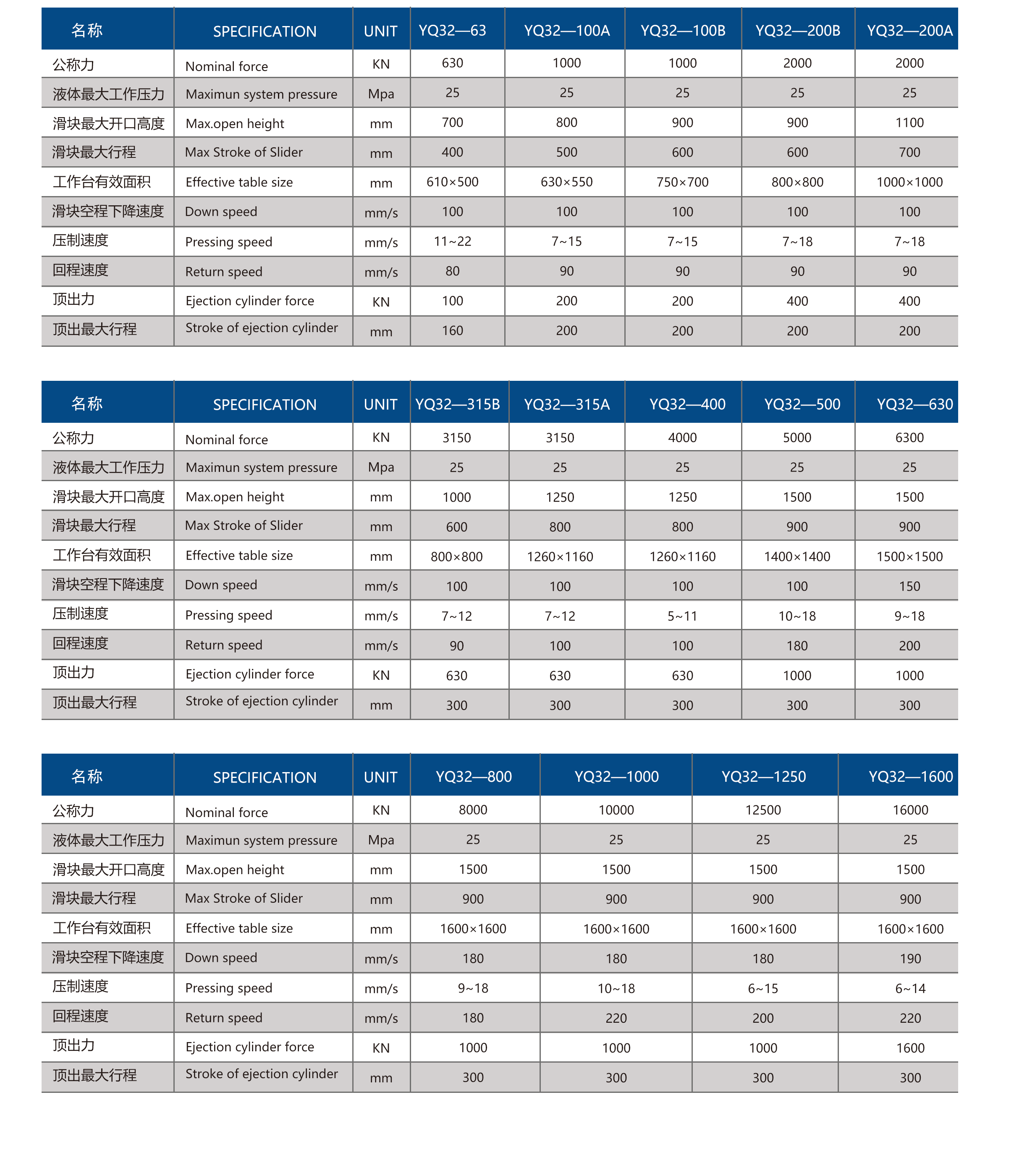

1000 ٹن چار کالم ہائیڈرولک پریس ایک قسم کا ہائیڈرولک ٹرانسمیشن ہے جس کا مرکز ہائیڈرولک ہے، جس میں رہنمائی اور حمایت کی ساخت کے طور پر چار کالم استعمال کیے جاتے ہیں، جو دھاتی/غیر دھاتی مواد کو دبانے، ڈھالنے، درستگی کے لیے استعمال ہوتا ہے۔ اس کی خصوصیت وسیع الاستعمالیت، مستحکم دباؤ اور ہموار ایڈاپٹیبلٹی کی وسیع حد ہے، اور درمیانے اور اعلیٰ درجے کی تیاری کی صنعتوں کے لیے اہم مشینری میں سے ایک ہے۔

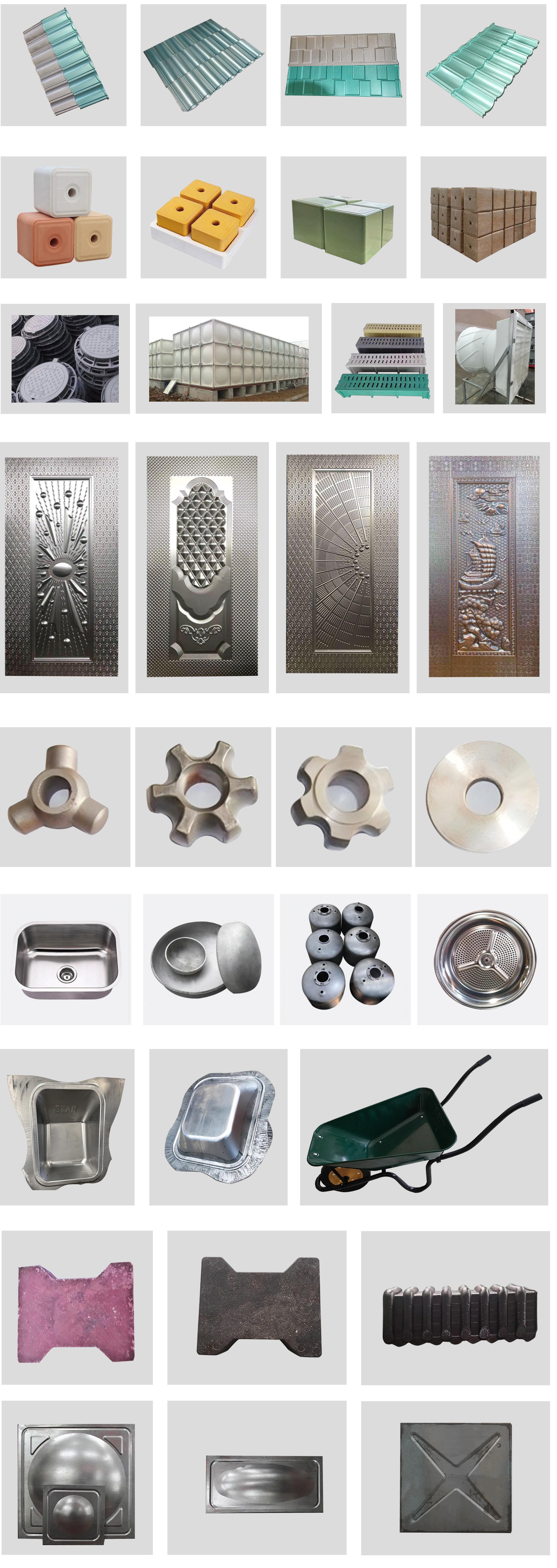

مضبوط عمومیت: یہ سانچوں کو تبدیل کرکے مختلف عملوں (دبانا، موڑنا، دباؤ وغیرہ) کے لیے مناسب ہو سکتی ہے، جو کثیر الجنسی چھوٹی پیداوار کے لیے موزوں ہے۔

اعلیٰ رہنمائی کی درستگی: چار کالم کی ساخت سلائیڈر کے جانبی بیرونی حرکت کو محدود کرتی ہے، جس میں متوازی اور عمودی دونوں میں کم غلطی ہوتی ہے، جو شے کی یکساں نوعیت کو یقینی بناتی ہے۔

اچھی دباؤ کی استحکام: ہائیڈرولک سسٹم تناسب والو/سرفو والو کنٹرول اپنانے کرتا ہے، دباؤ کی لہریں ≤ ± 2% جب دباؤ برقرار رکھا جاتا ہے، لمبے عرصے تک دباؤ کے اطلاق کی ضرورت والے عمل کے لیے موزوں (مثلاً مرکب مواد کی تشکیل)۔

زیادہ قیمتی فائدہ: فریم ہائیڈرولک پریس کے مقابلے میں، چار کالم ساخت کی تیاری میں کم مشکلات ہوتی ہیں، مرمت کرنا آسان ہوتا ہے، اور مجموعی لاگت زیادہ مناسب ہوتی ہے۔

خودکار تیاری: باڈی کو کور کرنے والے حصوں، انجن بلاک، چیسس کے اجزاء کے ڈھالنے اور ماڈلنگ کے لیے استعمال ہوتا ہے، تاکہ پیداواری صلاحیت اور درستگی میں بہتری لائی جا سکے۔

مرکب مواد: FRP سیپٹک ٹینکس، ونڈ ٹربائن بلیڈز، اور آپٹیکل فلموں (جیسے BOPP/PET) کی ماڈلنگ، مواد کی یکساں ساخت اور طاقت کو یقینی بنانے کے لیے۔

پاؤڈر دھات سازی: سمنٹیڈ کاربائیڈ، نایاب زمینی مقناطیس، سلیکون کاربائیڈ مصنوعات کو دبانے کے لیے، جو زیادہ کثافت اور زیادہ مضبوطی کی شرائط کو پورا کرتا ہے۔

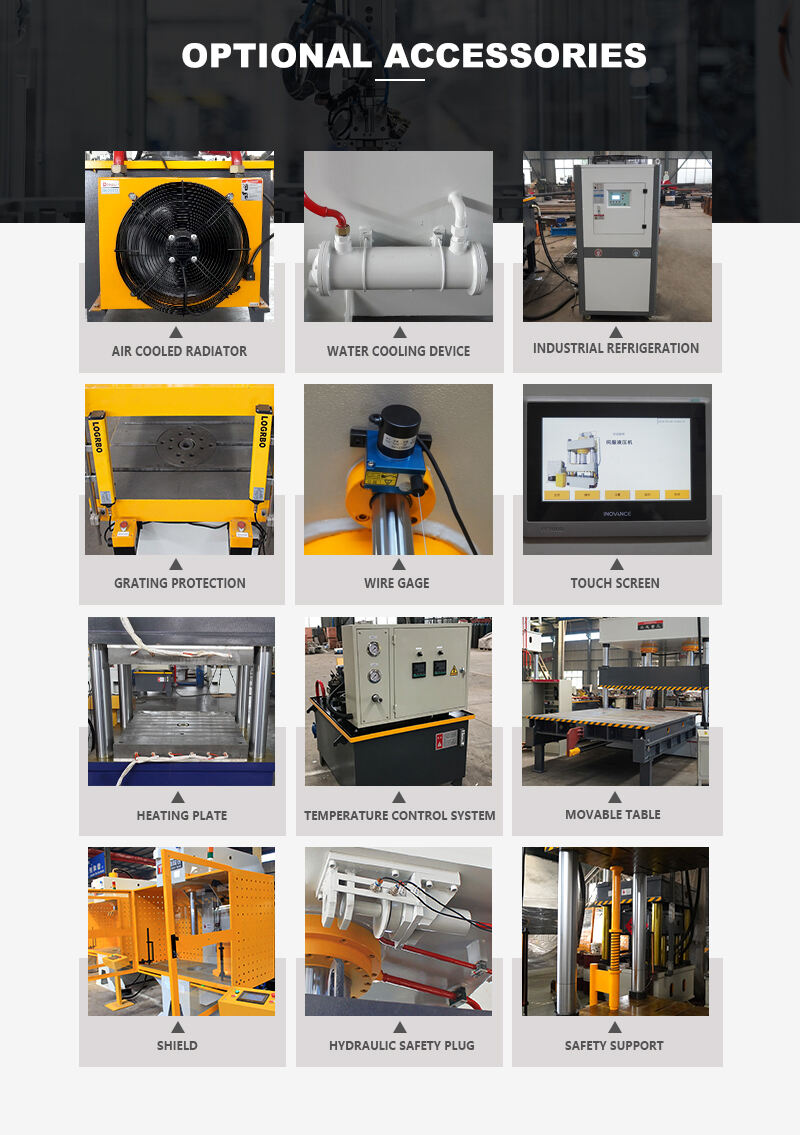

ہم مکمل بعد از فروخت خدمات پیش کرتے ہیں، جن میں تنصیب، کمیشننگ اور آپریشن تربیت شامل ہے؛ پریس مشین کے صارف مینول فراہم کرنا تاکہ صارفین کو پریس مشین کو چلانے اور اس کی دیکھ بھال کرنے کا طریقہ سیکھنے میں آسانی ہو۔

ہم کئی نپے ہوئے ڈیزائن حل اور کامیاب صارفین کے کیسز کے ساتھ مکمل طور پر ہائیڈرولک پریس مشینری فراہم کرتے ہیں۔ ہم خالہ بنانے والے آلات اور مطابق پیداوار لائن مشینری کے ساتھ کسٹمائز خدمات بھی فراہم کرتے ہیں، صارفین کے لیے ون اسٹاپ سروس فراہم کرتے ہیں۔ مشاورت کے لیے ہمیں کال کرنے کا خوش آمدید۔

ہمارا دوستانہ ٹیم آپ سے ملنا چاہتی ہے!

کاپی رائٹ © ندوں مشینری مینیفیکچر کمپنی، لیمیٹڈ. تمام حقوق محفوظ ہیں - پرائیویسی پالیسی