Ever thought of the force with which machines press things together? It's pretty amazing! There is a kind of machine that does this exceptionally well, and it's known as a hydraulic press machine. Although hydraulic presses are a little bigger and bulkier, they also work like biomechanical presses, except that they utilize fluid (a gas like air or a liquid) to create great pressures to tightly press the materials together. This is critical in many places where things must be produced fast and correctly. Also its capacity is 200ton, which means 60 ton hydraulic press by a company name Nadun. To give you a little perspective of just how heavy that is, it’s like pushing down with the weight of 33 huge elephants at once on 200 tons of pressure! That’s a lot of power!

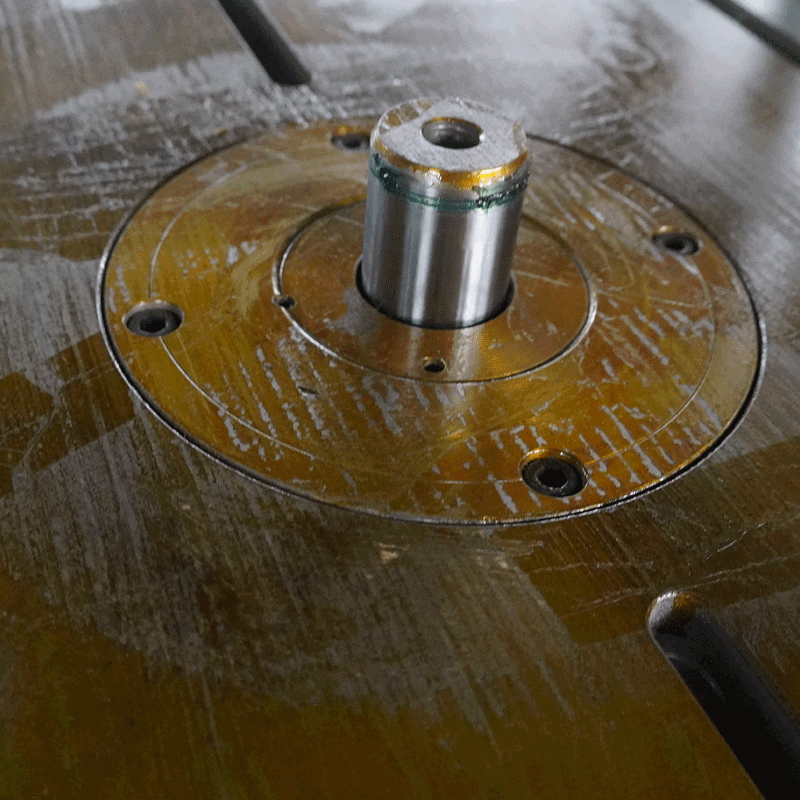

A special system inside the machine creates the strong force of a 200 ton hydraulic press. Such system is a hydraulic system. There are two cylinders in a hydraulic press machine — a big one and a small one. As you operate the machine, a hydraulic system forces liquid into the smaller cylinder. This causes the big cylinder to apply significant pressure downwards on the materials that require pressing. Which is also the reason hydraulic press machines play a huge role in producing many different things. Much force can be applied to the items pressed, meaning that the products created are resilient.

what a 200 Ton Press Can Do Ndun’s 100 ton hydraulic presss can do many jobs. These machines are very versatile. It is because they can be used in many different ways. For example, they help make items from various materials. This includes plastic and metal. A hydraulic press can create all kinds of shapes and sizes. It is very helpful in this way for many industries out there. Ndun’s machines use a 200 ton press to press materials with the right amount of force and accuracy. It is essential because it ensures that all manufactured items come out correctly. One of the great things about a 200 ton hydraulic press is it works very quickly. A 200 ton press can press very fast. It saves time and money while making things. When a machine can work quickly, it means that more things can be produced in less time. These machines are accurate, too. Companies need to make the exact airplane and car parts for the safety and performance of these vehicles. how to use a hydraulic press: Using a hydraulic press machine might seem hard at first. However, it is not too difficult once you understand how it works. First, ensure the workers place the materials they want to press on the machine. This is an easy step. However, workers should check if the materials are centered on the machine carefully. The material should be in the center, as this ensures it gets pressed straightly.

When everything is all set and prepared to go, the hydraulic press machine can be turned on. The hydraulic system will push liquid into the smaller cylinder, and this pushes the larger cylinder down onto the material that needs to be pressed. These controls can modify the pressure, speed, and motion of the press. Stabilization is needed to ensure a material is not overpressed, creating a sustainable, finished product.

Hydraulic press machines are widely utilized by industries due to their efficiency and precision. They are used to manufacture many items we use every day. They are often used to make car components, such as metal skin panels and engine parts. 200 ton hydraulic press machines that are used in shaping & molding of metal sheets which are used in cars is Nadun's pack. This is also helpful in assembling the parts that fit perfectly together.

Hydraulic press machines are also used to produce strong cardboard boxes. The machine compresses the cardboard into a solid, thick mass. This is vitally important because items need to be housed in robust boxes that can endure shipping and storage conditions. Hydraulic presses are also employed in the manufacture of other plastic products, including PVC and polystyrene. These substances are incorporated into numerous everyday products, including toys and containers.

With more than 17 years of expertise, Nadun Machinery emerged as a leading exporter and manufacturer in the processing of metals. We concentrate on hydraulic presses, punch presses shearing machines, bending machines and vertical lathes caters to different industries such aerospace, automotive manufacturing mechanical engineering, construction, and metallurgical engineering. Our 200 ton hydraulic press machine are distributed in more than 150 countries around the world and set new standards for manufacturing machinery.

Nadun Machinery products are known their superior quality, excellent performance, and long service lives. Nadun Machinery has an experienced research and development team comprising more than ten employees each with an average of more than 10 years of experience research and development. Our team is always improving innovating to keep up with changing 200 ton hydraulic press machine demands.

Our company manufactures 500-600 sets (sets) of various products every year. We also provide installation and commissioning 200 ton hydraulic press machine for over 400 customers each year. Our products been certified by ISO, CE, SGS as well as other certifications. Our commitment to excellence is reflected in the numerous product innovation patents we hold well as the certificates of honor have received.

In the area of cooling products, Dragon and Tiger brand and Temple Heaven brand in order to meet the broad market demands, a range of products can adapt to various consumers and usage scenarios. The company's goal to be an elite company in the health field is based the development brand products, health-related products, and the user 200 ton hydraulic press machine.

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy