Mechanics and Operation of Hydraulic Bearing Press Machines

These machines help us a lot in making different products. As you can easily guess, a machine speeds up the manufacturing process by thousands of times. A particular machine useful in factories, this is called a Hydraulic bearing press machine. This automatic hydraulic press machine is used to press bearings in a quick manner onto other parts of machines. These Nadun offer support to various machine parts hence need such equipment in case you have a problem which is preventing the bearings from functioning appropriately.

A variety of applications that you will find using a hydraulic bearing press for the most part, this is so popular it works much better than using hands to do all of that labor. The simplicity of the tasks that this machine can perform more quickly also has a distinct advantage to any manufacturing situation. Machines take some of the jobs, which aids in maintaining smooth and trouble-free running. As Nadun automated hydraulic press is capable of performing numerous tasks in a fast and safe manner. They are indeed a great way to prevent manual creep accidents, but their true value as tools that increase the safety of workers and operators cannot be underestimated.

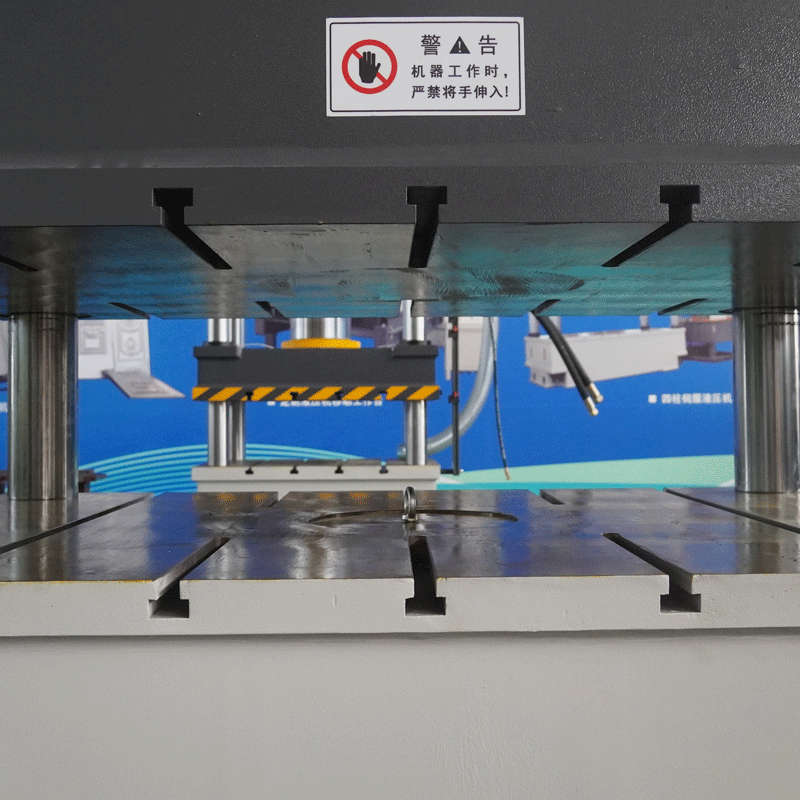

As per the requirements, hydraulic bearing press machine is available in various shapes and sizes. These are to be used for a variety of jobs, particularly in areas where there is heavy work load like construction and manufacturing. Take, for instance the H-Frame Hydraulic Shop Press able to press up to 6 tons. These are often used in fabric and metalworking manufacturing, where a strong compaction pressure is required. There is also a miniature model, the automatic hydraulic press. It is a table top machine, thus suitable for electronics and consumer goods. Four-Column Hydraulic Press: This Nadun type can accommodate bigger bearings, and is used mainly in construction or marine work. All of these tools are engineered to deliver the proper amount of force for certain jobs.

The hydraulic hot press machine is highly accurate and save a lot of time. They give workers greater control when pressing and this helps get the jobs done more efficiently. This control of surroundings results in higher outputs as workers can do more with the reduced time. Because of the fact that a lot is done automatically by machines, employees do not have very many manual corrections to make (which would take up much time). This will save not only time right now, but also makes it much and easier to run businesses.

Two of the most common workplaces in any mechanical workshop, and also in manufacturing environments that requires horizontal hydraulic press machine. In any production environment they are indispensable tools because the help in speeding up jobs of workers and this do it more safely. Most of the corporations would need these machines in numerous sizes, so they will opt for what quantity size is sort of applicable to them. The good news is that when a company which decides to buy hydraulic bearing press, they have clear ideas on what it will be used for and how much power they need along with where the machinery unit fits in their workshop. Choosing the right option is very important for better productivity and to avoid any interruptions in your testing operations.

To meet the huge market demand for cooling items, Dragon and Tiger and Temple of Heaven brands offer various products can be adapted to number of different types of users and consumers. The company's commitment to become an industry leader in the health field is based on building brand product lines, Hydraulic bearing press machine products and user experience.

Our company produces 500-600 sets (sets) of a variety of products annually, and provides installation commissioning services for more than 400 customers every year. The products passed ISO, CE, SGS and other certifications. Our commitment to excellence is reflected in the many patents in the field of innovation for our Hydraulic bearing press machine and the certificates honor we've received.

Nadun Machinery is known for its high-quality products are renowned for their performance and the long-lasting durability of their service. Nadun Machinery researchers and developers with more than 10 people and an average of more than 10 years of experience in research and development. Our team continuously Hydraulic bearing press machine and innovating to meet changing market demands.

Nadun Machinery is a leading manufacturer and exporter metal processing equipment with over 17 years' experience. We concentrate on punch presses and hydraulic presses. We also provide the shearing machine and bending machine. Our products are sold in more than 150 countries across globe, Hydraulic bearing press machine new standards machinery manufacturing.

A decent hydraulic bearing press can massively alter how things are created in an industrial facility. These machines are used in various industries nowadays as they help to make jobs easier and faster. These are changing as technology changes, including the advent of digital controls and automation in general. But many models that were developed quite some years back more than serve their purpose today as well. It is another example of how even older technologies can still have value. This is one device that any big factory will never want to run out of - hydraulic bearing press machine. This makes sure that they are able to efficiently press bearings and other substantial duties through the manufacturing procedure.

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy