Do you realize just how crazy a 150 ton press is? In this article, we will look at some of the industries like manufacturing, construction, aerospace to automotive amongst others before covering further details about Smart Manufacturing.

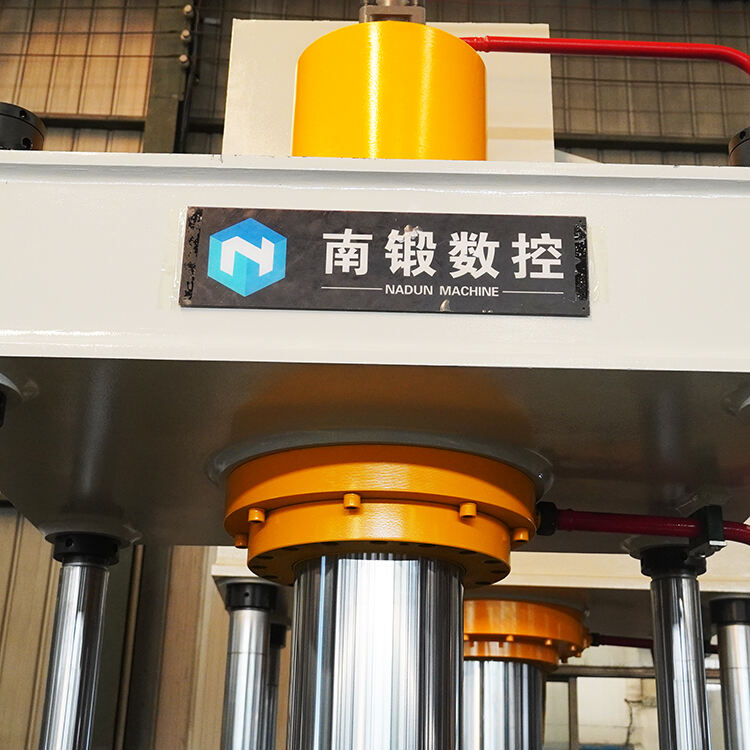

A Nadun 150 and 500 ton press uses hydraulic or mechanical force to generate a pressure output of approximately (you guessed it) 150 tons. This power is key to help it shape, bend and more importantly punch through various materials such as metal or plastic. These presses are offered in a number of configurations, from C-Frame to H-Frame and four-post, depending on the needs of your particular application.

Owing to their functionality in the production processes, 150 ton presses may be run manual manually or semi-automatically and fully automatically. Hydraulic presses can perform with precise accuracy a range of operations, such as stamping, blanking shearing deep drawing coining and bending.

Nadun 150 and 1000 ton press are precise and strong, often allowing for a constant high-quality performance even with intricate pieces or those that may be especially tough constraints. These presses come preconfigured with the custom dies, punches and tooling that are needed for your application to form material in desired shape, size and finish; even when working on large or heavy materials.

With best of class controls a 150 and 1000 ton press machine provides added features that allow the operator to control pressure, position and speed through defined parameters capture then adjust as they see necessary. This degree of scrutiny guarantees each piece is crafted to exacting standards and tolerances, which in turn Nadun press machine 1000 ton means less scrap produced as a result that improves the overall efficiency and safety on an assembly line.

For manufacturers and fabricators that need large amounts of force for heavy-duty stamping and forming, such as piercing, embossing, or blank coin production without a money-sucking overhead cost attached to it, the 150 ton large hydraulic 10 ton press is one machine which is extensively used. Their small footprint, easy installation and low maintenance/energy needs relative to larger scale machines routinely used.

In addition to better filling, the 150 ton presses have a faster cycle time and run at higher speeds than their smaller counterparts yet maintain precision and quality. If 100 and 15 ton press results in 15 minutes less of setup per day you have a powerful, if that equates to any labor savings or lower lead times on order.

Our company produces 500 600 sets (sets) of different items each year. It also 150 ton press installation commissioning services for more than 400 customers every year. The products we manufacture have been approved by ISO, CE and SGS. We are the proud owners several innovation patents as well as honorary certificates which demonstrates our commitment to excellence.

Nadun Machinery is known for the high-end products it produces which are 150 ton press for their performance their long-lasting service life. Nadun Machinery's research and development team has more than 10 people, with more than 10 years of experience in field of research and development. Our team is continuously improving innovating to meet evolving marketplace demands.

Nadun Machinery is a leading manufacturer and exporter metal processing machines with more than 17 years of experience. Our primary focus is on 150 ton press presses and hydraulic presses. We also offer the shearing machine and bending machine. Our products are distributed in more than 150 countries across globe which sets new standards manufacturing machinery.

In the area of cooling products Dragon and Tiger brand and Temple of Heaven brand in order to meet broad market demand, a variety of products be adapted to a variety of consumers scenarios of use. The company's 150 ton press to become an elite company in the field of health is based on the development of brand product lines, health products and the user experience.

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy