These machines are considered as an important part of many industries for several centuries. They make various things such as cars, buildings and even airplane componens. The Advanced Press MachinesToday, press machines have been widened to an extent with hundreds-to-thousands-of-tons capacity reach in case of manufacturing sector so as to pave their own way up.

The 1000 ton press machine is one of the giant Machine tool in which we are obtained usful force that similar to weight few hundred elephants. It is this immense power that enables the device to cut, shape and even bend some of the toughest materials on earth such as steel, copper or aluminum. Well to start, these machines have a >100k N " useable" force ( in house designed and built 50 ton scale actuator ), as second they are big.... maybe up to 50000kg... a special foundation to stand and maintain balance on.

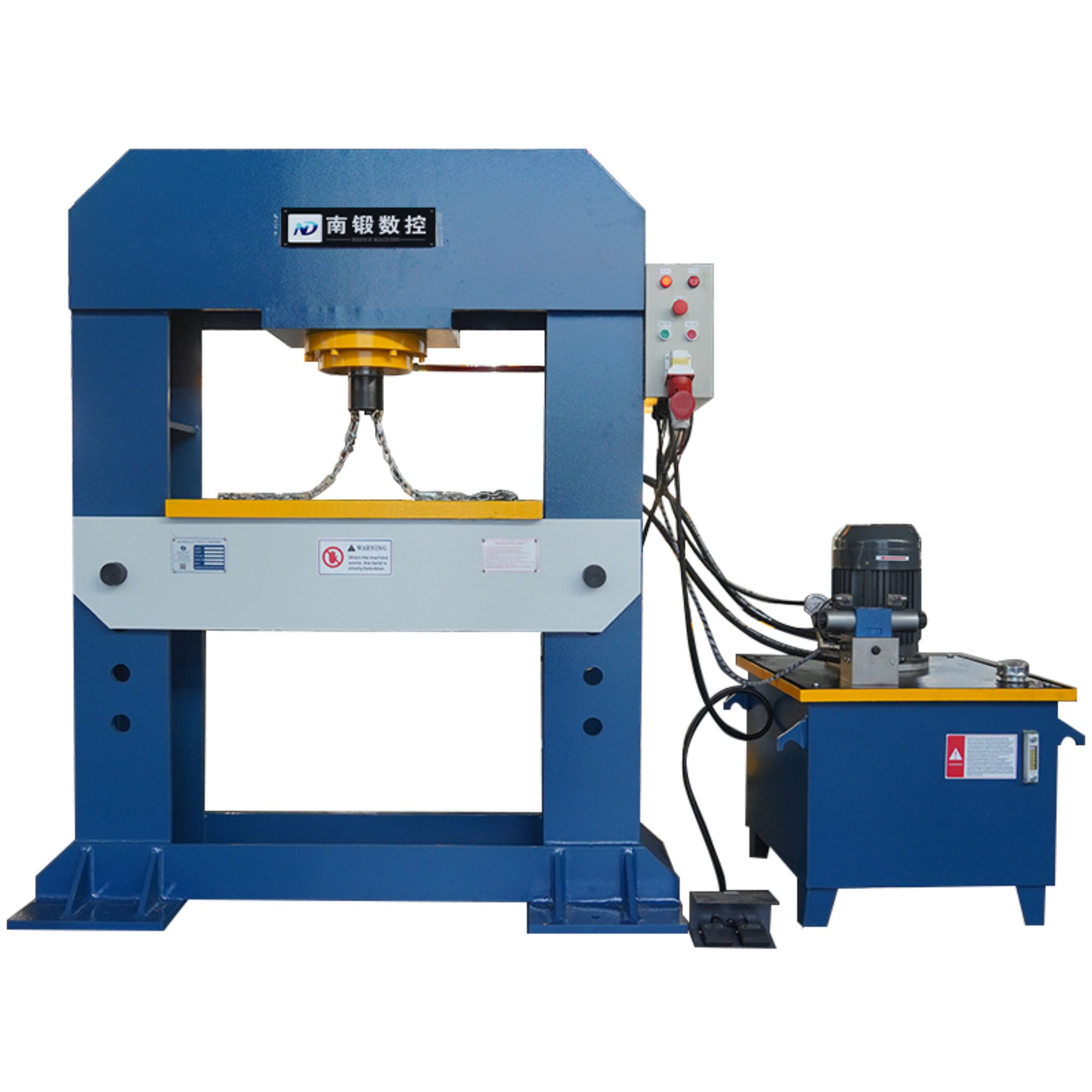

There are lots of the 1000 ton press machine partendas This is the technology that makes up the foundation of a press table using high-pressure hydraulic systems good for 1000 metric tons worth of force. This is operated by a hydraulic cylinder and it provides the force needed pressurize or deform materials whatever being machined. The typical hydraulic pressure cookers include a piston rod through, and although the cylinder moves back or forth in accordance with type of application.

One such change, one of the landmarks mentioned previously in manufacturing began 1000-ton press machines. Stuff like making pieces the same shape and generating uniform styles which would be difficult or impossible to do by hand is one of their first uses when compared with doing so hands-on. So, it implies that 1000 ton press machine is capable of processing the immense quantity of material which will lead to offering high-speed products for a manufacture and thus also favorable lesser Lead-time as well. The project has saved money for manufacturers and they want their share to extend commensurate with which bigger bids will be allowed in hand over of the products on time. They have also been instrumental in advancing research and development across various industries where testing of materials processes designs that can be done at a fraction of the time or resource cost.

AutomotiveThe 1000-ton press machines are often used in the automotive industry for such applications as vehicle body parts, doors or panels and also chassis making. In construction, the machines are used to cut and then shape materials quicker and safer where they can be handy for cutting steel beams or pipes so that you have a 1000-ton press machine which is another type of heavy hydraulic equipment as it allows us to create fast but very robust columns ensuring effective building methods ( huge antennas out od thin air). It consists also widely employed in aerospace industry due intensive use aluminum-stretching manufacturing processes necessary lightweight yet strong pressed parts like wings tail surfaces nacelles fairings wing skin most interior elements ex.

Rather than machine making parts, it is far less complex, reliable and faster in manner the manufacturing processes with the 1000-ton press machines integrated. These machines are often used by manufacturers to efficiently cut and shape materials with unerring precision, thereby saving time on waste and downtime. By using 1000-ton press machines, there is no end to the new solutions that companies can implement in harnessing this technology and delivering clients great parts faster and at a lower cost.

In conclusion it can be said that the coming of these 1000-ton press machines not only revolutionized manufacturing, but also helped immensely in enlarging and expanding production capacity in various sectors. Such as, the use of 1000-ton press machine are a key enabler for cars to be made lighter/wall then before and/or smart buildings or even aerospace parts. With the increasing maturation of this technology, and its wider establishment in mainstream application areas - The possibilities as to what AM can do have never been better - it has the ability to disrupt manufacturing across a global scale enabling companies around world realise unprecedented levels of product quality whilst driving ever greater efficiency- Product : PRODUCTIVITY.

Nadun Machinery products are known for high quality, excellent performance, and long-lasting service. The research and design team includes over 10 people, with more than 10 years experience in the field of research and development. They 1000 ton press machine to innovate improving our products in order to keep up the ever-changing needs of the market.

The company provides installation and commissioning services over 400 customers every year. It manufactures between 500 and 600 sets diverse products each year. Our products have been certified by ISO, CE, SGS and other certifications. Our commitment to excellence be seen in numerous patents in the field of innovation for our products as well as the 1000 ton press machine of honor we've received.

In the area of cooling products, Dragon and Tiger brand and Temple Heaven brand in order to meet the broad market demands, a range of products can adapt to various consumers and usage scenarios. The company's goal to be an elite company in the health field is based the development brand products, health-related products, and the user 1000 ton press machine.

With over 17 years of expertise, Nadun Machinery has emerged a prominent manufacturer and exporter in the metal processing industry. We focus on hydraulic presses, punch presses shearing and bending machines, and vertical lathes that serve diverse sectors such as aerospace, automotive manufacturing, construction, mechanical engineering, and metallurgical industries. Our products 1000 ton press machine across 150+ countries and regions across the globe creating new benchmarks production of machinery.

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy