A 60 ton hydraulic press is one of the most robust machines used to transform metal into more forms. And this is a truly important machine and so used in numerous places where metal is used very widely, for example due to the automobile, plane and buildings factories. AdvertisementThe hydraulic metal press works by using a specific fluid for pressureproduction. This pressure is what helps to push, bend and form the metal into whatever shapes are required.

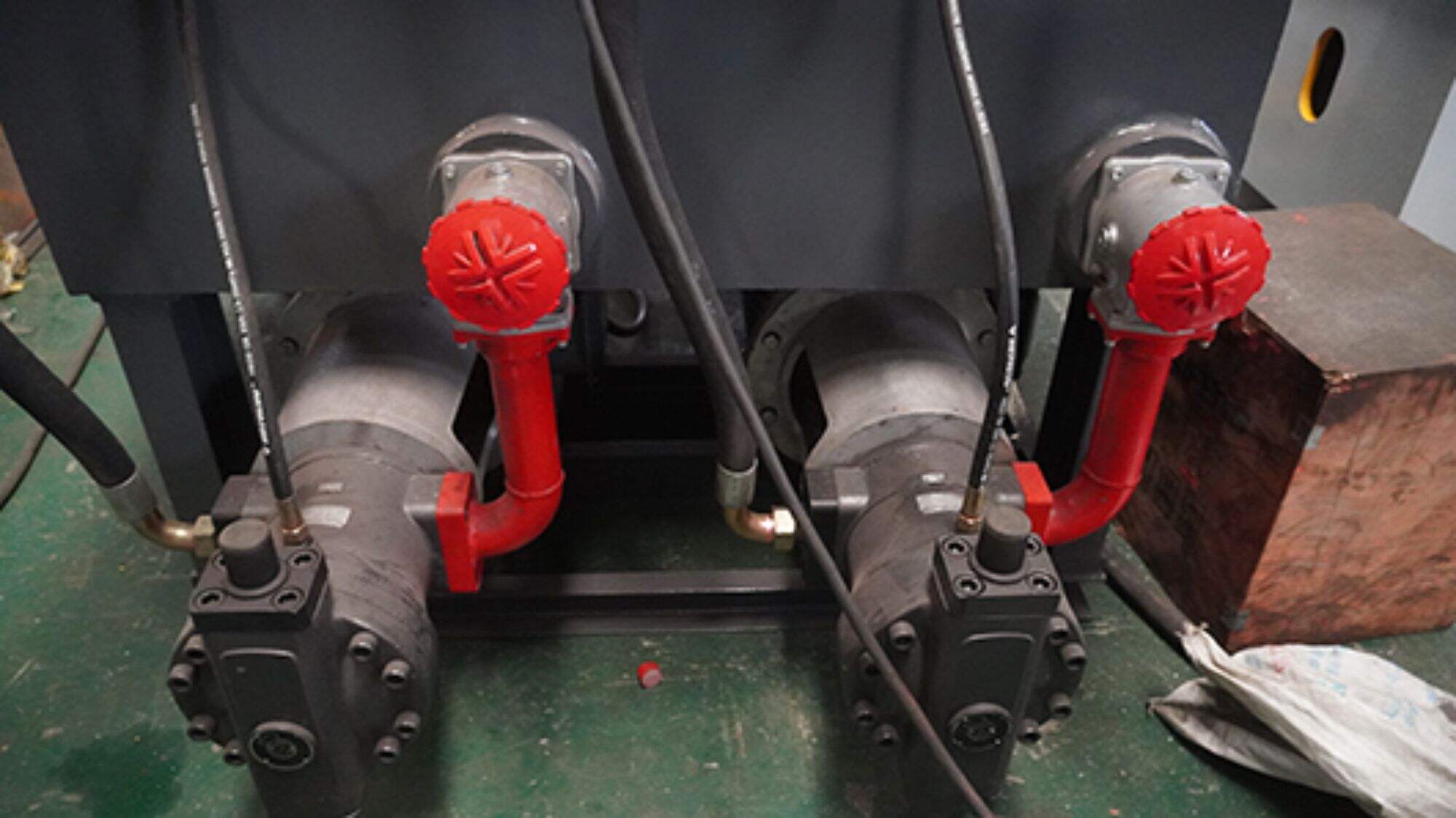

A 100 ton hydraulic press consists of two main components that work in tandem, the hydraulic pump and the hydraulic cylinder. A hydraulic pump pushes a high-pressure fluid into a cylinder when a person pushes a button or pulls a lever. Inside the cylinder, this generates pressure, resulting in force. This is what applies pressure to the metal piece that puts it into the desired shape. It is similar to squeezing a sponge: When you squeeze, the sponge deforms.’

Key Features Quality Material: Nadun cover the base material of the hydraulic metal press with high-quality materials that so ensure long term durability. The chassis is coated in durable powder coating and is constructed of solid, robust steel to handle the pressure when stamping foundational metal. It essentially means that the machine works through the intensive process without a breakdown. The cylinder is also made out of high quality steel, to ensure that the hydraulic press has the strength and durability to withstand any work. Its durability means that it can be used numerous times without getting worn out easily.

The approach boosts task efficiency by providing faster and neat finishing of the operator works in metal trades. This allows them to produce more products within less time, saving on the cost of labor. You press things, you make holes, you stamp things and you forge things. These tasks help ensure that metallic parts are manufactured with high degrees of repeatability and precision. Consistency: Everyone makes each piece exactly the same every time, very critical when dozens or hundreds of parts need to be created.

For the thick and heavy metal, the hydraulic metal press is your best bet. The Class is able to impart a tremendous amount of force, making it extremely easy to nudge even the thickest of metals into your desired shape. Hydraulic metal press designed so well, that it can even work continuously for hours without any issues. That reliability makes it a calculated choice for any metalworking project, regardless of size.

With more than 17 years of expertise, Nadun Machinery emerged as a leading exporter and manufacturer in the processing of metals. We concentrate on hydraulic presses, punch presses shearing machines, bending machines and vertical lathes caters to different industries such aerospace, automotive manufacturing mechanical engineering, construction, and metallurgical engineering. Our hydraulic metal press are distributed in more than 150 countries around the world and set new standards for manufacturing machinery.

The company provides installation commissioning to more than 400 hydraulic metal press each year. It manufactures between 500 and 600 sets diverse products each year. These products have been certified by ISO, CE and SGS. Our commitment to excellence is reflected in many product innovation patents we hold the honorary certificates we've received.

Nadun Machinery products known for their quality, exceptional performance and long-lasting service. Nadun Machinery has the research and development staff comprising more ten employees who have an average of over 10 years of research and development experience. They are always innovating developing our products to hydraulic metal press the changing market needs.

To meet the huge market demand for cooling items, Dragon and Tiger and Temple of Heaven brands offer various products can be adapted to number of different types of users and consumers. The company's commitment to become an industry leader in the health field is based on building brand product lines, hydraulic metal press products and user experience.

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy