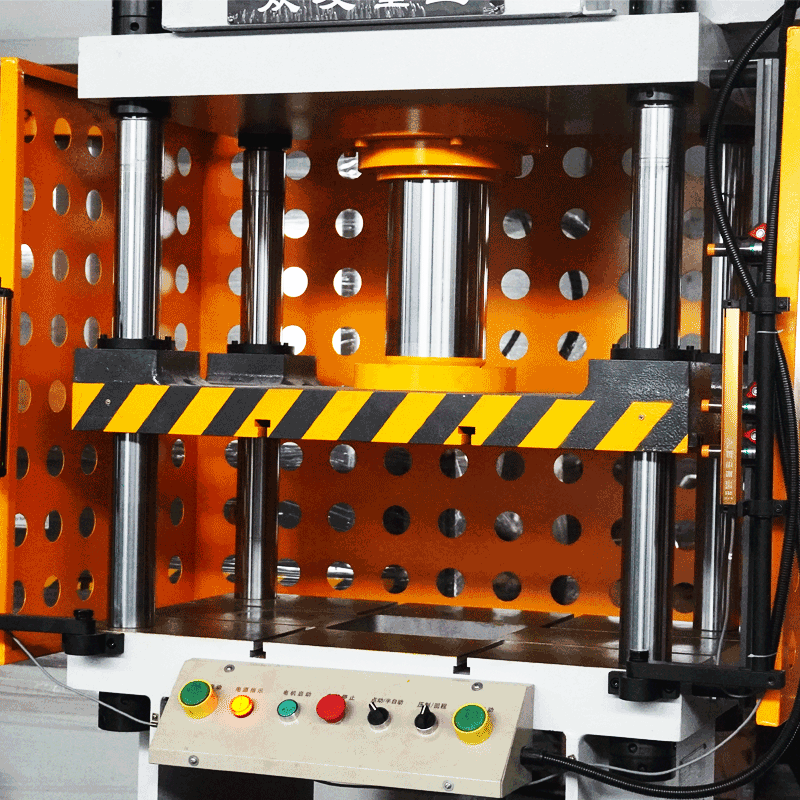

The 60 ton hydraulic press uses hydraulic power to do its work. This means that it can apply a very heavy downward force on a sheet of metal. Working principle is thus the force from the machine is distributed evenly, which creates shaping the metal the best way suited with the machine. This amazing force means it is faster and easier to use this machine than hammering metal by hand. This quickness is vital when a factory must output many components in a brief time.

One of the other major advantages is hydraulic stamping is very accurate.. Precision means that the machine can be fine-tuned to apply exactly the right amount of force required to form the part you’re trying to create. This ensures that every single metal section is uniform, which means they are all identical in dimension. High-precision components are essential for a variety of applications, and this machine monitors production to verify they are manufactured correctly.

If the goal is cranking out as many metal bits from your factory as it can, a hydraulic stamping press is the ultimate machine. It can process big metal parts, so multiples are placed in the machine and pressed at the same time. It can also adjust the shapes and sizes of the individual parts as necessary.

You can accurately and instantly build metal parts using a hydraulic stamping press that was never possible before. So this means you can do more in less time. This is beneficial to meeting production deadlines, which is extremely critical in a busy factory environment. So on-time production also helps the entire plant / factory run smoothly.

Hydraulic stamping machine is very versatile which is another great thing about it. Versatile means that it can effectively perform many different jobs. That is an indispensable tool of any factory working with metal, and it is capable of pressing metal into a great diversity of such shapes and sizes.

That machine allows you to construct all the parts, from simple things like brackets all the way to more complex metal components that are necessary to build various projects. Also the 100 ton hydraulic press can be adjusted to suit for metallic sheets of different thickness. This of course makes it very convenient, as it is usable for wide array of projects (large scale or small scale alike)

With the press activated, an oil pump pumps a volume of oil into the cylinder which pushes the piston. Once again, as the piston moves downwards, it forces the metal sheet into a desired shape. A light Metal part can be created, followed by a heavier Metal part with the same hydraulic press tool as they can deliver high pressure.

Nadun Machinery products known for their quality, exceptional performance and long-lasting service. Nadun Machinery has the research and development staff comprising more ten employees who have an average of over 10 years of research and development experience. They are always innovating developing our products to hydraulic stamping machine the changing market needs.

Our company manufactures 500-600 sets (sets) of different products every year. We also provide installations commissioning more than 400 customers every year. The products have received ISO, CE, SGS as well as other certifications. We hold several product innovation patents and honorary certificates that show hydraulic stamping machine to excellence.

Nadun Machinery is a leading manufacturer exporter of metal processing machinery with more than 17 years of experience. We concentrate on hydraulic presses, punch presses, shearing machines, bending machinery, and vertical lathes. We serve various industries like aerospace, automotive manufacturing, construction, mechanical engineering, and metallurgy. Our products hydraulic stamping machine across 150+ countries across the globe, setting new standards manufacturing machinery.

In the field of cooling products, Dragon and Tiger brand and Temple of Heaven brand order to meet the broad market demand, a variety of products can adapt to various consumers and use scenarios. With brand building as the mainstay focus, health products being the primary focus, and user experience as the base and firm is hydraulic stamping machine to establishing itself a world-class company in the health sector.

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy