Ever wonder how some of your daily-use things get manufactured? It might be the metal spoon with which you eat; or the sturdy frame of your car. Most of these objects are made with the use of a specialized machine known as a 60 ton hydraulic press. This machine has a really integral part in creating many of the things we see in front of us.

A hydraulic press is a high powered machine whichs work by compressed fluid to do big push on the material which you are working on. It walks you through how to save one of its own and the sense of relief washing over you as you return them to safety, leaving you with tears in your eyes; the sheer horror of it all is more than enough to shatter anything, be it metal, plastic, or rubber. One of the most exciting things about this machine is the varied shapes it can take — this allows it to be extremely useful in hundreds of factories.

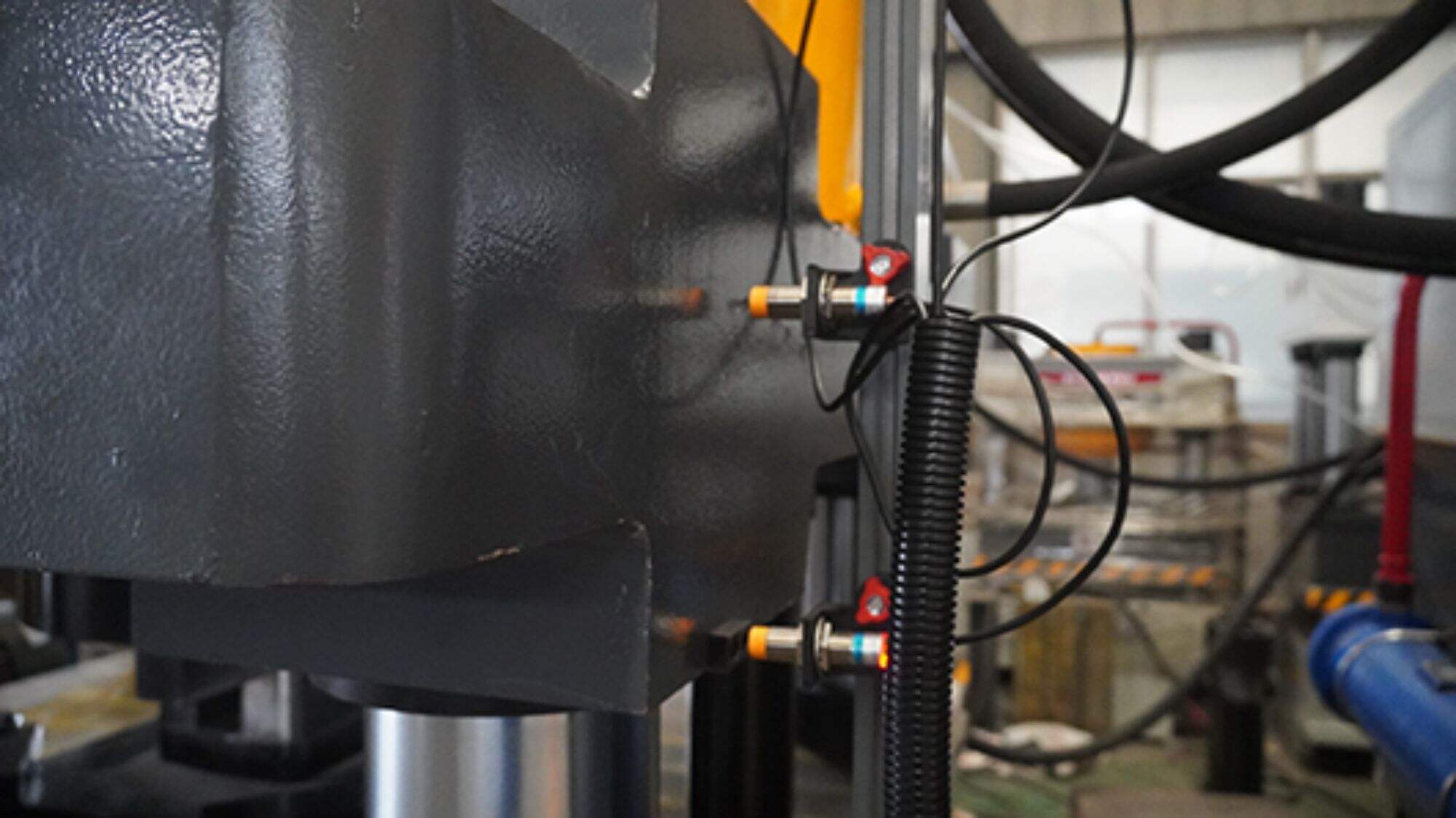

Now let us take a deeper look into how the 60 ton press works. This includes two components: the hydraulic cylinder and the ram. Special hydraulic fluid is housed in the hydraulic cylinder. So you have this fluid shifting around in the cylinder. As the stoichiometric ultimate flows, it acts on the ram. It is the ram part that presses the material to be shaped. The ram exerts a tremendous amount of force that, when pushing down, will mold or crush the material.

The hydraulic powered press can go through many different types of raw materials to create products of intent. It has many uses for example it can flatten aluminum into wide sheets for diverse applications. It can also control the shape of rubber, creating things like tires for cars and even soft grips for tools. Steel can also be bent into tough pieces used in buildings and machinery. There are almost limitless options for what it can create!

So what makes the powered hydraulic press so crucial in manufacturing? For one, it is highly versatile; a multitude of products can be made from it. This provides a value-added tool for several sectors. Secondly, it has high-speed efficiency and accuracy rates that aid factories in producing products on time. Finally, a powered hydraulic press is more eco-friendly than some manufacturing processes. It gives off less waste and takes less energy, which is great for our planet.

One of the things that has really revolutionized the way things are made in the modern day is the hydraulic press. It has accelerated production, reduced costs and has made work a lot easier. It’s one of the great things about this machine that people have safety.” The press does much of the heavy lifting, so workers do less manual labor and have a lower risk of injury.

And yet, despite all these advantages, the use of powered hydraulic press is still not widespread in many factories. There are tons of new products you might be able to make that are exciting. That is one of the new ways they are used, helping in making 3D-printed molds. Because manufacturers can 3D print a mold and then use the hydraulic press to turn materials into that mold — to create very complex parts with minimal waste. With this merged technology the process is more efficient.

Nadun Machinery is known for its high-quality products are of high-performance, as well as the long-lasting durability of their service. Nadun Machinery's research and development team includes more than 10 members, each of whom has over 10 years of experience in research and development. They are constantly powered hydraulic press and improving our products order to satisfy the needs of the market.

To meet the wide market demand for cooling items, Dragon and Tiger and Temple Heaven brands offer various products that can be adapted to different customers and use powered hydraulic press. With brand building as the foundation and health products as the focus, and user experience as the base and the firm is dedicated establishing itself as world-class company in the health sector.

Nadun Machinery is a leading manufacturer exporter of metal processing machinery with more than 17 years of experience. We concentrate on hydraulic presses, punch presses, shearing machines, bending machinery, and vertical lathes. We serve various industries like aerospace, automotive manufacturing, construction, mechanical engineering, and metallurgy. Our products powered hydraulic press across 150+ countries across the globe, setting new standards manufacturing machinery.

Our company produces 500-600 sets (sets) of a variety of products annually, and provides installation commissioning services for more than 400 customers every year. The products passed ISO, CE, SGS and other certifications. Our commitment to excellence is reflected in the many patents in the field of innovation for our powered hydraulic press and the certificates honor we've received.

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy