For example, a 60 ton hydraulic press is a giant machine that bends metal into different shapes. This is so because you can create various items using it, from car and pipe parts to airplane pieces. The press brake pushes the metal into a V shape by using a special tool known as a "die". The die can be likened to a mold, or a form that casts the metal into the shape you want. This is a heavy-duty item that can run even the thickest metal, so it is ideal for parts that must be solid and long-lasting.

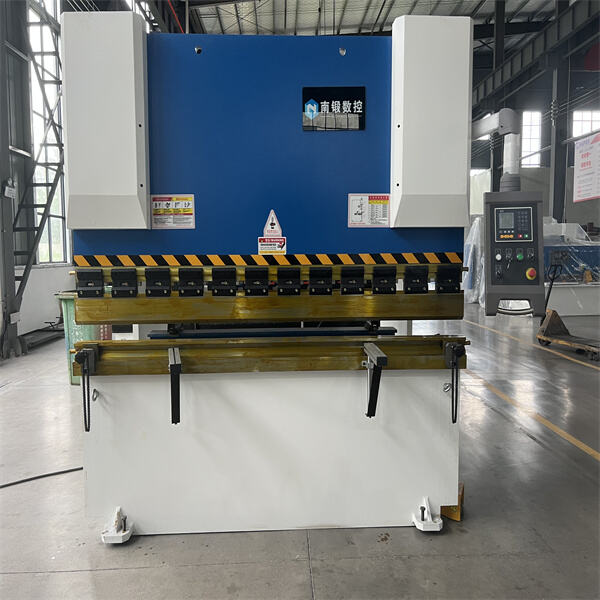

A press brake is a forming tool used for bending sheet and plate material, most commonly sheet metal. It has a large flat metal plate on its underside known as a bed. This is the bed where you put the metal sheet. A clamp to hold the sheet metal in position—so that it doesn’t move, as the machine works on it. Once you have the metal clamped down, something called a punch drops down from above and presses the metal into the die. This is a die which is the shaping tool that forms the metal into the final design that you want. By using different cuts, you can make different shapes. And this is how a press brake bends and shapes metal!

You can create parts much quicker with a 60 ton press than if you were manually doing it. This is key, as time in a factory or production line is valuable. Compared to a press brake, you can also make shapes that are more precise and repeatable. That means rather than spend ages hand shaping each individual piece, you are able to produce thousands of parts in less time. These are some simple tips that will keep your press brake outdoing itself:

Choose Right Tools - It is essential that you are equipped with the appropriate tools & dies for the job at hand. That means choosing the right materials, the right thickness and the right angles for your parts so that they are made just so.

Selecting the correct type of press brake is dependent upon your specific project requirements. A mechanical press brake is a good option for small jobs, or when you don’t need to produce many parts. If you are dealing with heavier material, or larger projects, a hydraulic press brake will work much better. If you require a combination of speed and accuracy, then the pneumatic press brake is the way to go.

Following the latest techniques and trends is another way to ensure quality. You may like to read more to know about new technology and the best practices so that you may upgrade your production to another level and work more efficiently.

Regular maintenance on your press brake is crucial to keeping it in great working order. This will require you to maintain the machine regularly so that it will function properly and will last long. You should absolutely take care of some of the following maintenance tasks:

To meet the huge market demand for cooling items, Dragon and Tiger and Temple of Heaven brands offer various products can be adapted to number of different types of users and consumers. The company's commitment to become an industry leader in the health field is based on building brand product lines, press brake products and user experience.

The company provides installation and commissioning services over 400 customers every year. It manufactures between 500 and 600 sets diverse products each year. Our products have been certified by ISO, CE, SGS and other certifications. Our commitment to excellence be seen in numerous patents in the field of innovation for our products as well as the press brake of honor we've received.

With more than 17 years of experience, Nadun Machinery has emerged a leading manufacturer and exporter in the processing of metals. We concentrate on punch presses and hydraulic presses. We also supply shearing machines bending machines. Our products are sold across 150or more countries and regions worldwide, establishing fresh benchmarks machinery press brake.

Nadun Machinery products are known for their superior quality, excellent performance, and long service lives. The company home to a research and press brake team that is more than ten each with an average of over 10 years of research development expertise. Our team is always improving innovating to satisfy changing requirements of the market.

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy