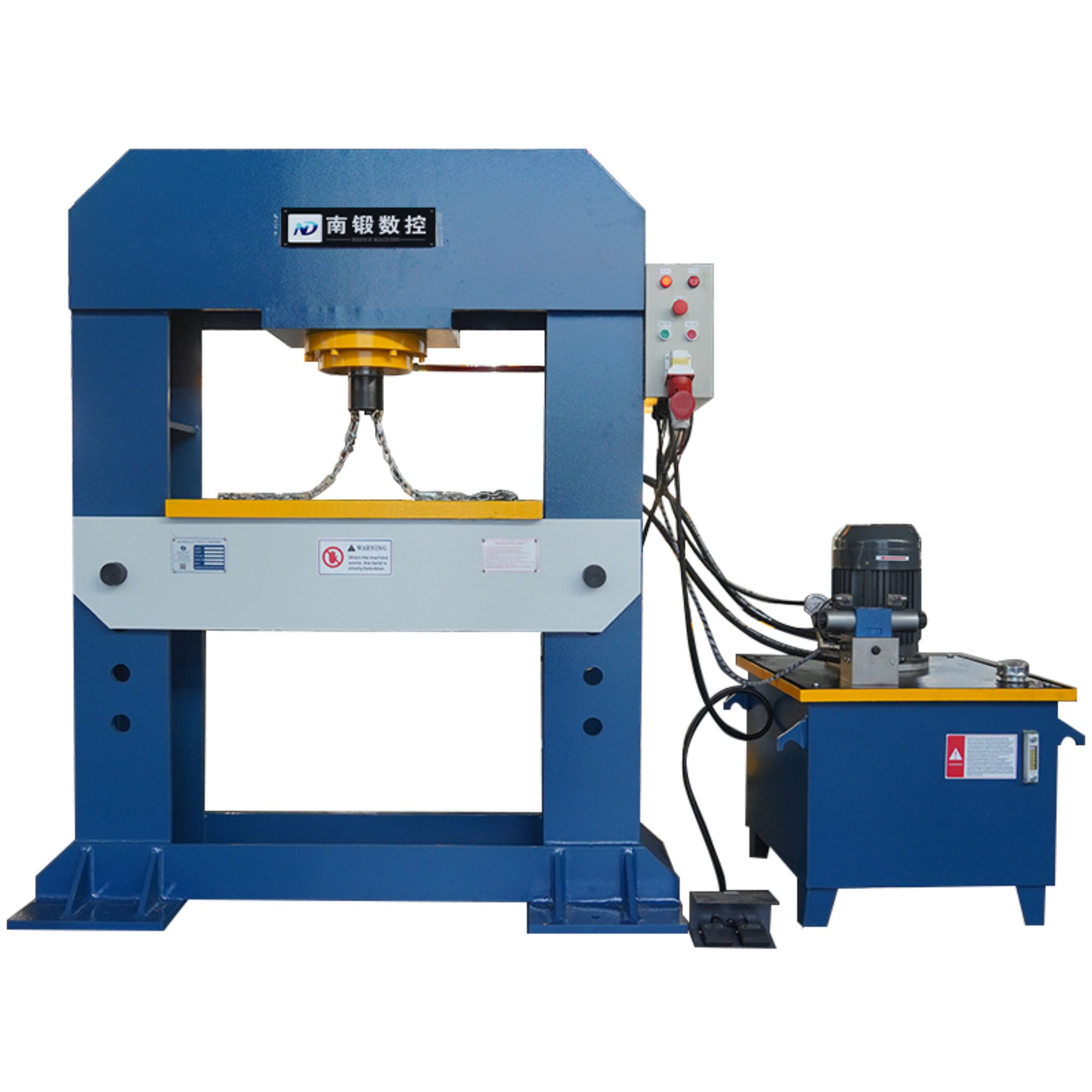

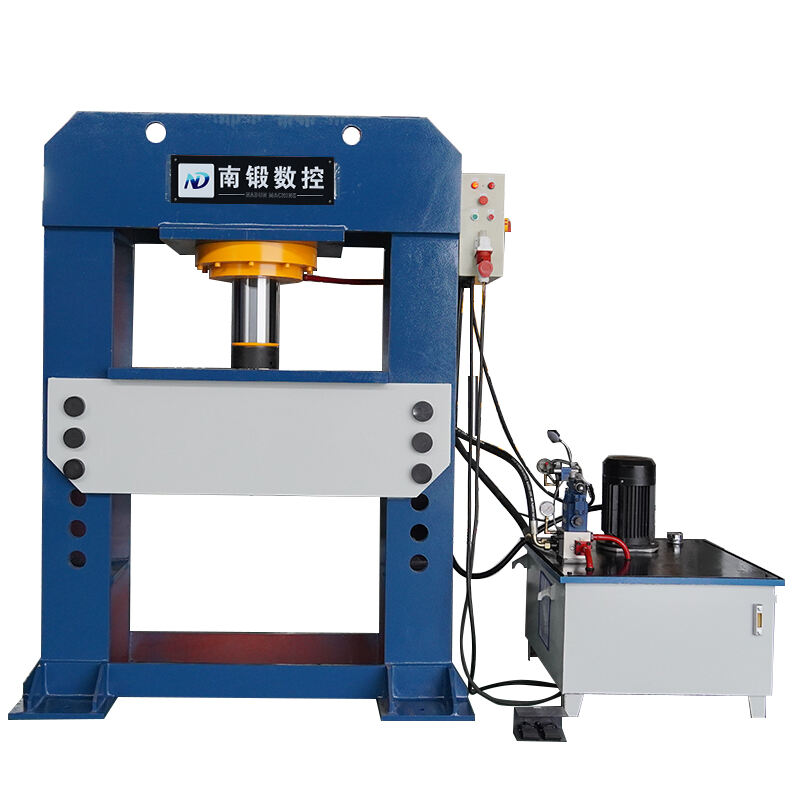

Nadun Machinery Manufacture Co., Ltd.

frein métallique hydraulique

Donc le presse hydraulique de 60 tonnes est une classe d'outils utilisée pour plier de belles formes dans la tôle en acier pour obtenir la forme et la taille souhaitées. C'est une machine importante pour de nombreux travaux de tôlerie. Il est crucial de savoir comment utiliser cette machine correctement et en toute sécurité. Dans ce guide, nous aborderons comment utiliser un frein hydraulique métallique, les avantages d'un frein hydraulique pour le travail de la tôle, quelques astuces pour maintenir votre machine en bon état, les différences entre les freins hydrauliques et mécaniques, ainsi que certaines règles de sécurité importantes lors de l'utilisation de cet équipement.

Configurer l'angle de pliage : Réglez la machine à l'angle de pliage approprié pour le métal que vous utilisez. Cela s'effectue généralement via un panneau de commande monté sur la machine ou par des ajustements manuels. Si vous souhaitez réaliser des pliages précis, afficher l'angle est extrêmement important.

Les avantages d'un frein hydraulique pour métaux dans la fabrication de tôles

Serrer le métal : Une fois que le métal est en position et que l'angle a été défini, abaissez soigneusement la partie de serrage de la machine. C'est ce qui maintient le métal en place et l'empêche de bouger pendant que vous le pliez. C'est également une étape importante pour garantir que le pliage sera précis.

L'un des outils les plus courants pour façonner la tôle est un presse hydraulique de 100 tonnes parce qu'il vous donne des pliages extrêmement précis. Il peut être très difficile de reproduire ce niveau de précision avec des outils manuels. Adapté à une gamme plus large de travaux, cette machine est également conçue pour des pièces de tôle plus épaisses et plus longues. Elle permet également aux freins hydrauliques de plier plusieurs pièces de métal simultanément, ce qui économise beaucoup de temps et d'efforts. Cela a une valeur particulière dans les grands projets où de nombreux composants doivent avoir la même forme.

-

Meilleurs conseils d'entretien pour votre frein hydraulique pour métaux

Surveillez l'huile : Vérifiez quotidiennement le niveau d'huile hydraulique dans la machine. Assurez-vous que l'huile est également remplie jusqu'à son maximum si elle est basse. Savoir quand l'huile doit être changée est crucial pour garantir que la machine continue de fonctionner en douceur et efficacement.

-

Comparaison entre les freins hydrauliques pour métaux et les freins mécaniques pour métaux

Serrez les pièces - Vérifiez la machine de temps en temps, au cas où certains vis, boulons ou écrous seraient desserrés. Si vous remarquez des pièces desserrées, assurez-vous qu'elles sont bien resserrées pour éviter un usure inutile de la machine. Effectuer des vérifications régulières évite les problèmes ultérieurement.

-

Précautions de sécurité à garder à l'esprit lors de l'utilisation d'un frein hydraulique pour métaux

Lubrification des pièces mobiles : Il s'agit d'un travail de maintenance important, et un lubrifiant doit être appliqué aux parties mobiles de la machine. Cela évite qu'elles ne se coincent et aide également au bon fonctionnement. Une bonne lubrification augmente la durée de vie de la machine.

Why choose Nadun frein métallique hydraulique?

-

Qualité et Performance Exceptionnelles :

Les produits Nadun Machinery sont réputés pour leur haute qualité, leurs performances exceptionnelles et leur longue durée de vie. L’équipe de recherche et de conception de l’entreprise comprend plus de dix spécialistes en freins hydrauliques pour métaux, chacun possédant plus de 10 ans d’expérience dans le domaine de la recherche et du développement. Notre équipe s’efforce constamment de s’améliorer et d’innover afin de suivre l’évolution des exigences du marché.

-

Une variété de produits

Dans le domaine des produits de refroidissement, les marques Dragon et Tiger ainsi que la marque Temple du Ciel répondent ainsi à une large demande sur le marché, avec une gamme de produits adaptée à divers consommateurs et situations d'utilisation. L'objectif de l'entreprise est de devenir une entreprise d'élite dans le domaine de la santé, basé sur le développement de produits de marque, de produits liés à la santé, et de l'utilisateur Hydraulic metal brake.

-

Expertise de l'entreprise et présence mondiale :

Nadun Machinery est un fabricant-exportateur de premier plan de machines pour le travail des métaux avec plus de 17 ans d'expérience. Nous nous concentrons sur les presses hydrauliques, les poinçonneuses, les cisailles, les machines de cintrage et les tours verticaux. Nous desservons divers secteurs tels que l'aérospatiale, la fabrication automobile, la construction, le génie mécanique et la métallurgie. Nos produits en frein hydraulique métallique sont présents dans plus de 150 pays à travers le monde, établissant de nouvelles normes en matière de machines-outils.

-

Qualité de produit fiable

L’entreprise assure l’installation et la mise en service pour plus de 400 clients chaque année. Elle fabrique annuellement entre 500 et 600 unités de produits différents. Ces produits sont certifiés ISO, CE et SGS. Nous détenons de nombreux brevets d’innovation produit ainsi que des certificats honorifiques, témoignant de notre engagement en faveur des freins hydrauliques pour métaux.

Catégories de produits associés

- machine presse hydraulique de 100 tonnes

- presse hydraulique de 150 tonnes

- presse hydraulique de 200 tonnes

- presse hydraulique de 300 tonnes

- presse hydraulique de 500 tonnes

- presse hydraulique de 1000 tonnes

- Presse hydraulique automatique

- Presse hydraulique automatisée

- Machine de presse hydraulique automatique

- Presse hydraulique pour roulements

- Machines à tour vertical

- Machine de presse hydraulique à matrices

Vous ne trouvez pas ce que vous cherchez ?

Contactez nos consultants pour plus de produits disponibles.

Demandez un devis maintenant

Contactez-nous

Droits d'auteur © Nadun Machinery Manufacture Co., Ltd. Tous droits réservés - Politique de confidentialité

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN