The first step in backing metal with a sheet metal pan brake is locating the metal in the tool. Ensure that it is lined up properly. After that, press down on the metal with the handle. As you continue to push the metal will begin to flex. It is crucial that the metal stays in the same position as it bends so it doesn’t go out of alignment. After completing all the bending, release the handle and gently remove the bent metal. This can take some practice, but you will improve with time.

To make quarters in the metal, you first have to lay out the corners: You can draw these lines with either a pencil or a marker. etc — To challenge the sharp corners, start the bend in the metal only slight. Go to the corner and bend a bit and move along the line. Bend the corner, then lock the metal into the brake before bending the other section. Remember, this will enable you to form clean and sharp corners without damaging the metal.

This is an important technique, creating a hem. Hemming is when you fold the edge of the metal over itself. This can be done by putting the metal at an angle on the brake and bending the metal over itself so one edge of the metal overlaps the other edge. Which makes the edge even stronger and safe. Once bent, lock the metal down firmly and press brake down all the way to finalize hem. This is a common technique for elements such as edges on roofs or other metallic elements that need to be sturdy.

When Curved Metal Needs To Be Flattened To achieve this, you must hang the metal upside down on the brake. Then slowly bend it a little bit, to start flattening it. Then, lock it down into place. Bend the metal flat. This method is best suited for if the metal is not overly thick, since thicker metals can be difficult to bend. Let's flatter curved metalMetal flattening is a method of creating a flat sheet of metal from some other form which is much less straight.

Making a box out of metal, you will have to make a few bends. First, measure your metal three times before you cut it. You should know how large do you want the box to be Bend the corners of the metal first, and then out to the sides. When you bend the metal, ensure that you lock it down to avoid it all moving around. Once all of your bends are done, you can assemble the box. This technique works particularly well for storage boxes or other shapes.

Have the flat metal parallel to the edge of the brake for good bending. That means it has to be kissing the brake the whole way across. Before you start to bend make sure that the metal is straight. (Presuming it is not straight, the bend is likely to not come out exactly.) And, prior to bending, mark the metal where you want the bend to start and where you want it end. Just make sure to measure and mark the metal at the angles at which you want it. It will help you create perfect bends, clean every time.

Metal Pan Brakes — require maintenance to keep them operating well. Maintenance is something you would want to do regularly. After you use it make sure to clean it up right away by wiping any dirt or metal shavings. For the moving parts, add a few drops of oil to get them working. This will make your tool perform better and last longer. Also using the correct types of metal (some of them bend nicely) The right materials will aid in keeping your tool from deteriorating and make bending easier.

To meet the growing market demand for cooling products, Dragon and Tiger and Temple of Heaven metal pan brake offer an array products that are able be adjusted to a variety of types of users and consumers. The firm's determination to become an elite company in the health sector is based on the development of brand products for health and wellness, as well user experience.

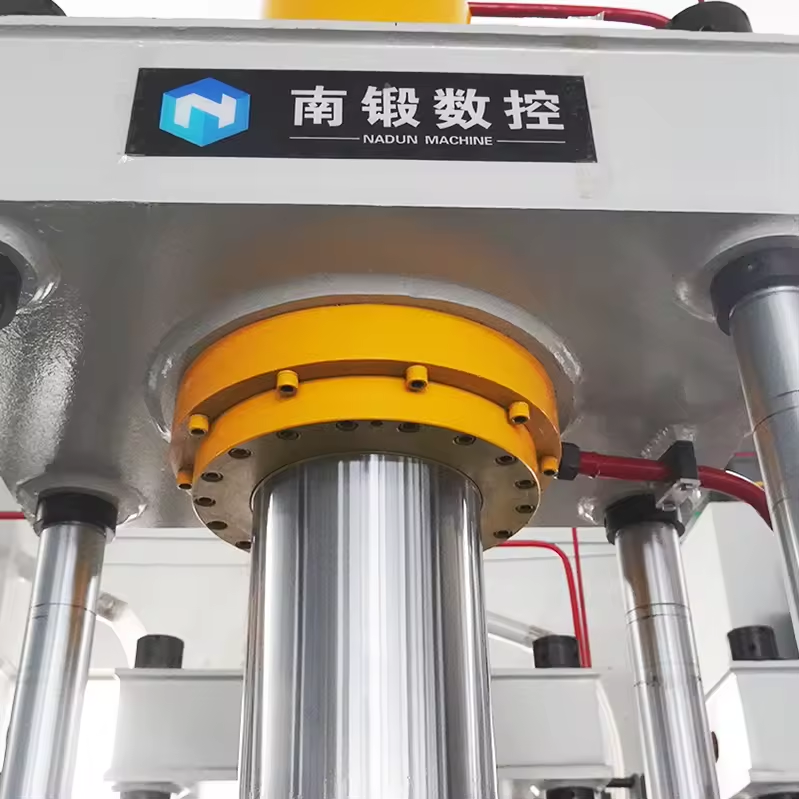

Nadun Machinery is known for its high-quality metal pan brake with outstanding performance, and long-lasting durability of their service. Nadun Machinery is researchers and developers of more than ten people each with an average of more than 10 years experience in research and development. They are constantly innovating developing our products to satisfy the needs of the market.

Our company produces 500 600 sets (sets) of different items each year. It also metal pan brake installation commissioning services for more than 400 customers every year. The products we manufacture have been approved by ISO, CE and SGS. We are the proud owners several innovation patents as well as honorary certificates which demonstrates our commitment to excellence.

Nadun Machinery is a leading manufacturer and exporter of metal processing machines with more than 17 years of experience. Our main focus is on hydraulic presses punch presses. We also offer shearing machines and bending machines. Our products sold across 150+ countries and regions across the globe, establishing fresh benchmarks metal pan brake manufacturing.

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy