|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

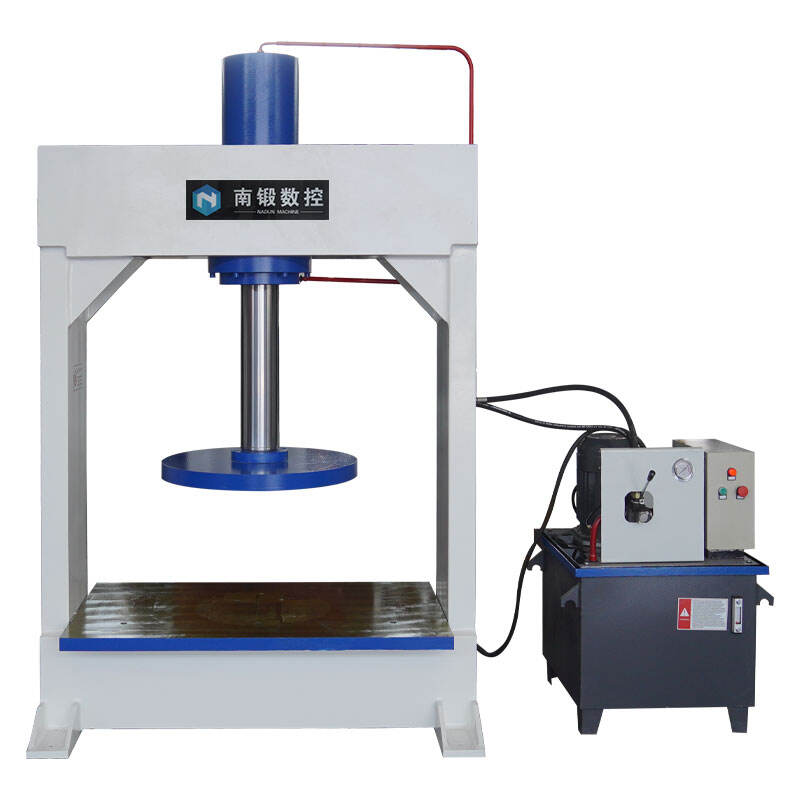

Model Number: |

YM-160T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

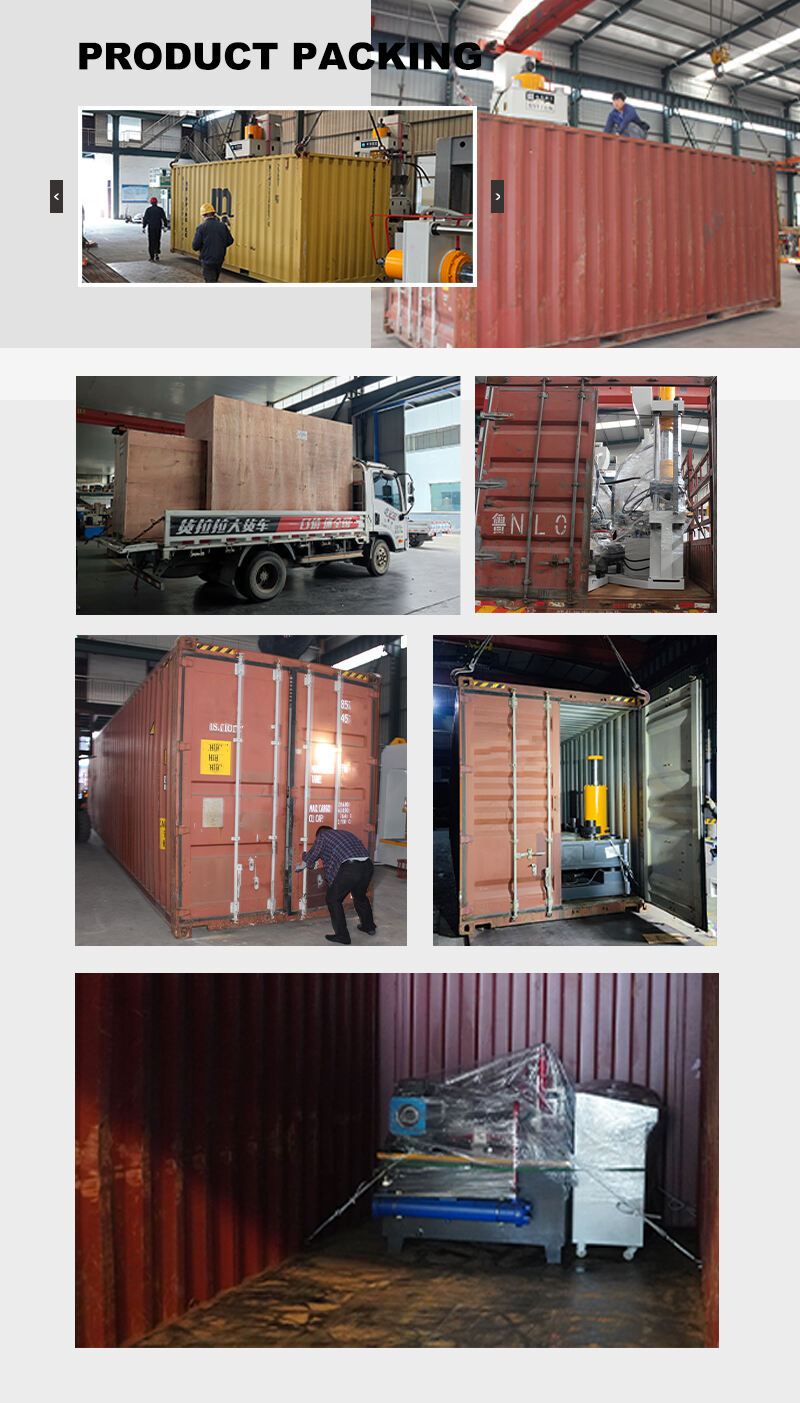

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

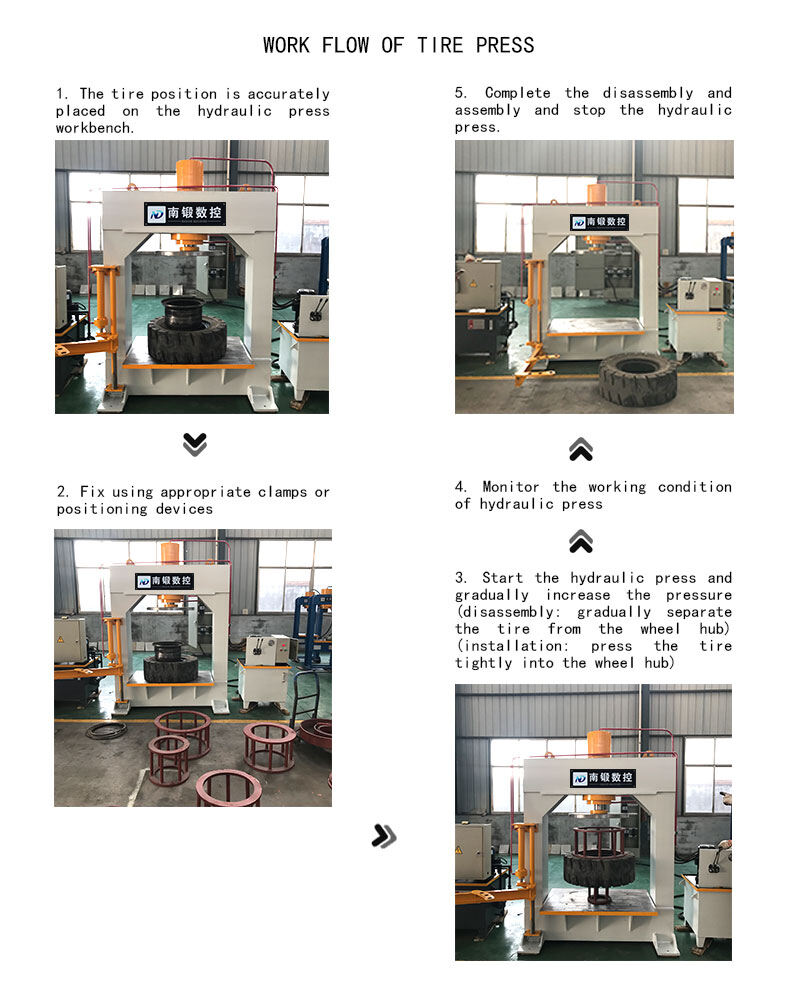

"Tire press is a kind of special equipment used for tire processing or recycling, its main function is to press tires (semi-finished products or used tires in the production of new tires) into a specific shape or state by mechanical pressure to meet the needs of the subsequent process. The main function is to press tires (semi-finished products from the production of new tires or used tires) by means of mechanical pressure into a specific shape or state to meet the needs of subsequent processes.

| Tonnage | Working Pressure | Cylinder Diameter/Rod Diameter | Effective Table Size | Opening Height | Stroke | Pressing Speed | Return Speed | Motor Power | Oil Pump Specification |

|---|---|---|---|---|---|---|---|---|---|

| 100 | 31.5 | D200/d100 | 1000x800 | 1100 | 500 | 7mm/s | 10mm/s | 5.5kw | 10McY (fixed) |

| 120 | 31.5 | D220/d110 | 1000x800 | 1100 | 600 | 6mm/s | 8mm/s | 5.5kw | 10McY (fixed) |

| 160 | 31.5 | D250/d150 | 1400x800 | 1100 | 600 | 6-12mm/s | 15mm/s | 5.5kw | 25McY (fixed) |

| 200 | 31.5 | D290/d160 | 1500x800 | 1200 | 600 | 4-9mm/s | 12mm/s | 5.5kw | 25McY (fixed) |

| 250 | 31.5 | D310/d180 | 1500x800 | 1200 | 600 | 6-12mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

| 300 | 31.5 | D360/d220 | 1500x800 | 1200 | 600 | 4-9mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

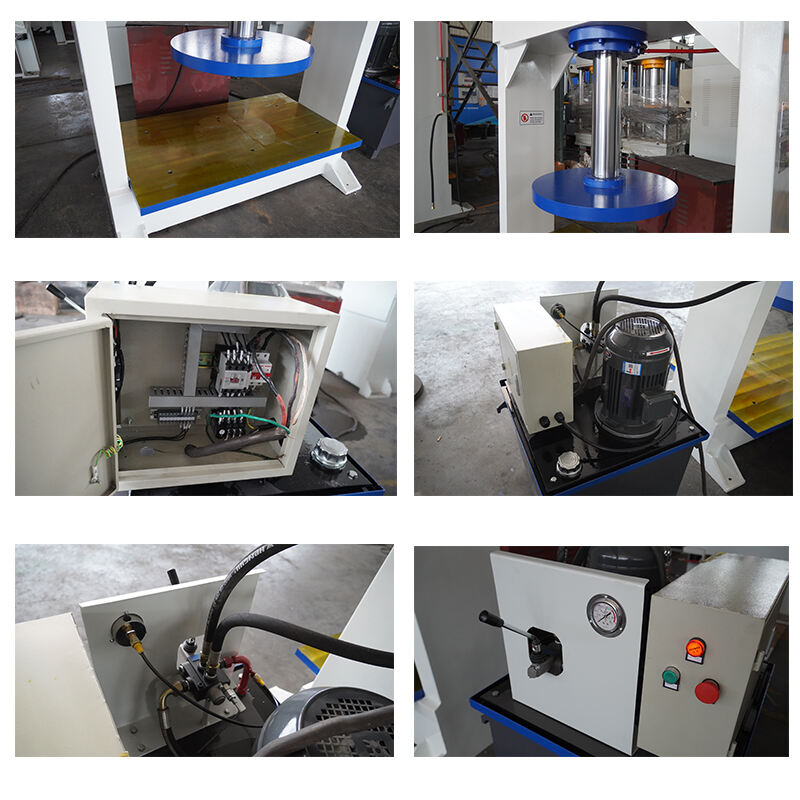

Hydraulic system configuration:

Driven by electric hydraulic station (motor power about 15-30kW), equipped with multiple sets of hydraulic cylinders (main cylinder + auxiliary cylinder), stable and controllable pressure. The hydraulic system supports stepless pressure regulation (the pressure can be adjusted according to the hardness of the tires), avoiding the problem of hard tires (such as steel wire tires) cracking or soft tires (such as retreaded tires) not being pressed.

Fuselage structure:

Mostly frame-type steel structure (some models with moving wheels), the overall rigidity is strong, can withstand high-frequency pressing (daily work 8-10 hours without deformation). Key parts (such as press head, cylinder, base) are made of Q345B alloy steel or 45# steel. Surface quenching treatment, wear resistance and impact resistance is better than ordinary steel.

Mold and indenter design:

The indenter is mostly flat or curved surface (adapted to different tire curvature), and some models support quick mold changing Some models support quick mold change (fixed by bolts or pins), which can flexibly cope with the flattening needs of different sizes of tires (e.g. car tires, SUV tires).

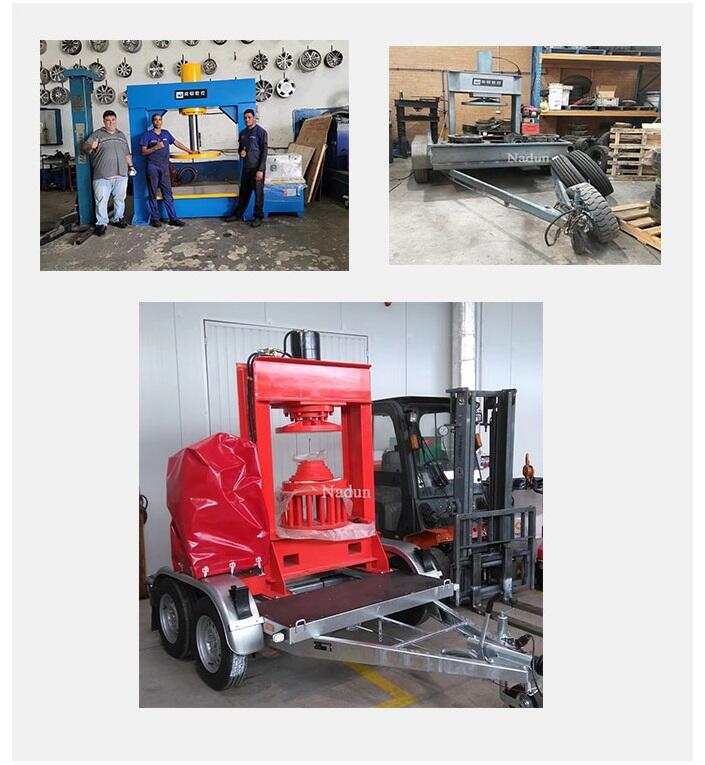

Type waste tire recycling station: processing old tires from neighboring auto repair factories and bus companies, flattening them and selling them to recycled rubber factories or rubber powder enterprises;

Tire retreading factories: pre-pressing old tires to be retreaded (removing surface debris and adjusting shape) to facilitate subsequent grinding and re-curing;

Rural/township tire service points: processing agricultural vehicle and motorcycle tires and solving the problem of storage footprint;

Small rubber product factories: auxiliary pressing of rubber blocks (e.g. raw material for seals), replacing traditional presses.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy