|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

Model Number: |

YQ41-250T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

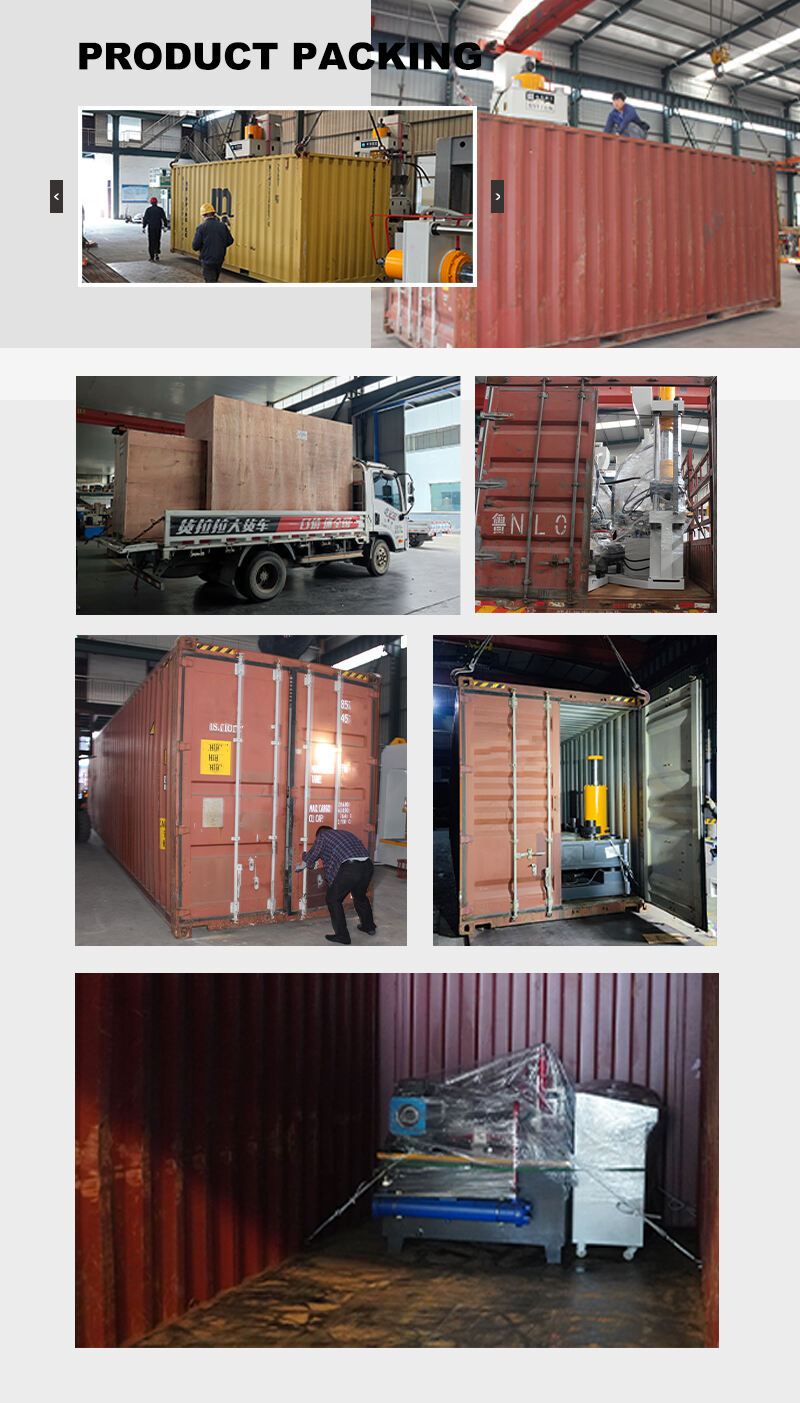

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

Single Arm Hydraulic Press is a kind of hydraulic equipment with C-type single arm structure, which is suitable for small and medium-sized workpiece molding process in the fields of metal processing, non-metal pressing, rubber and powder metallurgy. Its core function is to drive the slide movement through the hydraulic system to realize the operation of pressing, stretching, punching, straightening and so on.

| Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective Stroke | mm | 200 | 200 | 300 | 300 | 400 | 500 | 200 | 500 | 500 |

| Opening Height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat Depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downstroke Speed | mm/s | 160 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return Speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Worktable Width (Left to Right) | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Worktable Depth (Front to Back) | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Punching Hole Diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |

High flexibility: single-arm structure without two sides of the column cover, easy to large workpiece loading and unloading or multi-station operation;

Low cost: simplified structure compared with double column/four column hydraulic press.

Strong adaptability: through the replacement of molds can achieve a variety of processes (stamping, stretching, calibration), a machine multi-purpose

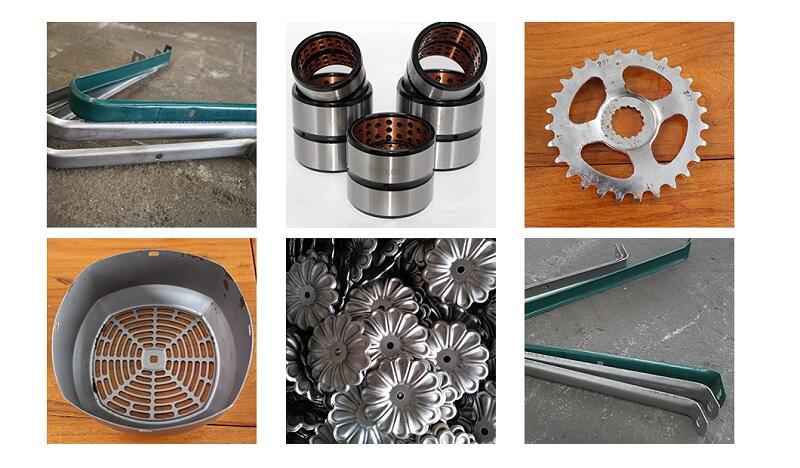

Metal Processing

Straightening and press-fitting: For the straightening of shaft parts and profiles, as well as press-fitting of bushing parts. For example, straightening of automobile motor shafts and press fitting of bearings.

Sheet metal forming: for bending, embossing and nesting of sheet metal. For example, stretch molding of kitchen and bathroom hardware (e.g. sink pulls).

Punching and unloading: With the punch buffer, the punching and unloading of metal sheets can be realized.

Non-metal processing

Composite material pressing: It is suitable for pressing and molding of plastic products and powder metallurgy parts. For example, carbon fiber reinforced plastic shell molding, product tensile strength up to 800MPa.

Rubber molding: for vulcanization pressing of rubber products, such as the production of seals and shock absorbing pads.

Industry Suitability

General machinery: machine tools, internal combustion engines, textile machinery and other industries, parts processing.

Home appliances and automobiles: assembly lines for washing machines, air-conditioning motors, automobile motors and other parts.

Military industry and three-funded enterprises: mass production of high-precision parts, such as precision shaft processing for military enterprises.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy