C Frame Presses: An Evolution To The Steel Fabrication Industry

In the manufacturing industry, machines are critical to produce a diverse array of products. C Frame Press - One machine that deserves a special mention due to its significance This creativity has almost changed the world of metal fabrication process, and it comes with a host of benefits. In an effort to organize all this information and provide a comprehensive overview, we split the article into 5 parts: Top five benefits of using C Frame Presses for metal fabrication Tips to choosing your best suited c frame press in workshop Maintaining longer lives on your practice c frame presses Why C-Frame Press is perfect choice when producing with high volumes How adopting them reshapes manufacturing industry

Following Are Top 5 Benefits of C Frame Presses in Metal Fabrication:

Value for money: C Frame Presses re cost-effective, space-saving and can be delivered quickly. In addition, they are low in maintenance cost so it is considered as a best option for small and medium sized workshops.

High precision: These presses can provide better accuracy and repeatability than traditional options. Hydraulic or electric drives ensure a uniform application of force during the forming process, thus ensuring fabrications are made to high-quality.

C Frame Presses are incredibly versatile, Capable of being used for many different metal forming operations which include but is not limited to Bending Embossing Punching etc. These features make them perfect for an array of metal fabrication methods.

Durability: C Frame Presses have a durable frame that can easily withstand pressures for extended periods of time, thanks to its sturdy construction in cast iron or steel (with aluminum).

Security: The C Frame Press also comes with emergency stops and overload protection, multiple safety features that help in taking care of the importantly for just about any working area plus assistance eliminate long term damages which can be caused considering through wanting operation.

A Comprehensive Handbook of How to Choose the Right C Frame Press for Your Workshop and Maintain it for Durability

To get the best from your C Frame Press there are factors to consider including:

Capacity: Select a machne that will meet the requirements of your metal fabrication projects.

Work Area: The press should have enough work area for the material you use.

Versatility: To enhance your capabilities, go for a C Frame Press that is flexible enough to allow it to undertake different metal-forming tasks.

Cost: Only buy a press that you can afford not only in terms of prize but also maintenance and usage costs in terms of energy.

Safety Measures: To protect not only the machine but also the personnel using it, prioritize machines that have taken safety measures seriously. It makes running the equipment easier.

Ten Important Maintenance Tips to Sustain Longevity of Your C Frame Press

Most C Frame Presses are expensive, and you will want to get the most out of them all the time. Here are ten important tips for the same:

Keep the machine clean all the time to avoid a buildup of dust.

Keep the machine parts moving by lubricating them all the time to prolong their shelf life.

Regularly clean or replace the hydraulic oil filter to avoid clogging.

Protect the machine from harsh climatic and weather conditions such as heat and rain.

In case of leakages from the cylinder or piston, planning for replacement is necessary.

Ensure to replace all worn out hydraulic hoses and fittings.

Check and replace any electrical components that are frayed.

Advantages of C Frame Presses for High Volume Production

High-volume manufacturing: C-Frame Presses are best-suited for high-rate production environments where they need to be placed under continuous or frequent operation. Both of these are structured so sturdy and designed to functioning without errors, resulting in the same output every time which is necessary for an efficient production process keeping their costs per fabrication down whilst staying within acceptable quality standards. In addition, its proprietary tooling system allows for fast setup changes from one production run to the next resulting in greater uptime and efficiency.

The manufacturing space is no more limited with traditional, slow presses rather it has peaceful and cost-effective C Frame Presses. They provide some of the advanced machines with high safety standards helping their employee to work in a very safe environment. C Frame Presses make fabrications of highest quality very fast and efficient through optimum tooling design, helps to Increase Industrial Production & Profitability.

Due to their affordability, precision, versatility and durability C Frame Presses now have become inevitable in all the metal fabrication industries which also satisfy health & safety requirements. The Top Press for Your Workshop and How to Keep it SingingChoose the right pressPress maintenance is every bit as important as getting a press selected in good order. High-volume manufacture is what C Frame Presses excels at, and it changes things up in the whole metal fabrication processes due to its transformative nature which makes this a game-changer across the industry for efficiency and perfection.

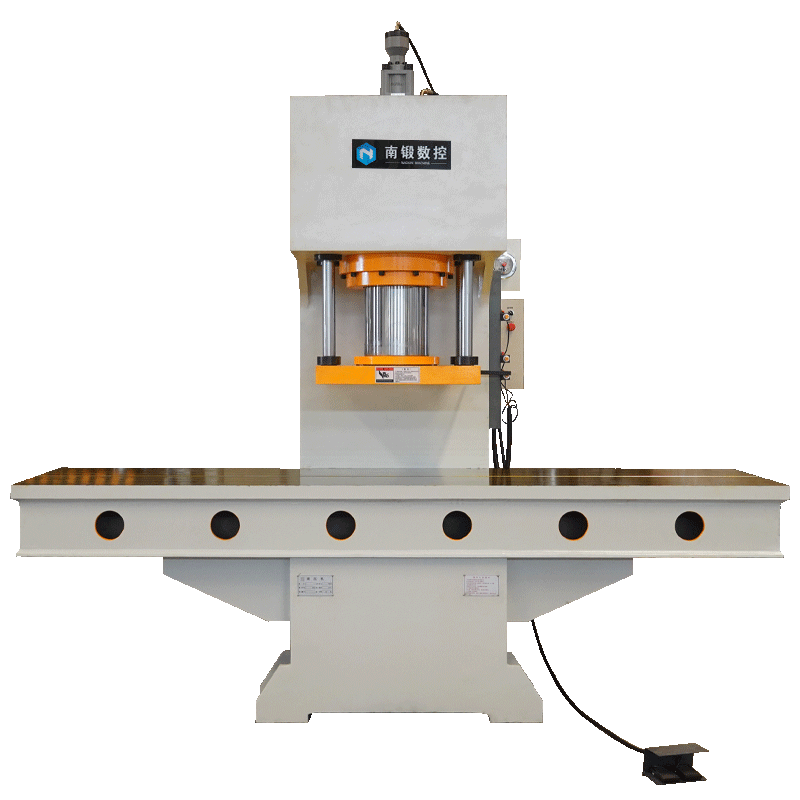

With more than 17 years of expertise, Nadun Machinery emerged as a leading exporter and manufacturer in the processing of metals. We concentrate on hydraulic presses, punch presses shearing machines, bending machines and vertical lathes caters to different industries such aerospace, automotive manufacturing mechanical engineering, construction, and metallurgical engineering. Our c frame presses are distributed in more than 150 countries around the world and set new standards for manufacturing machinery.

Nadun Machinery is known for the high-end products it produces which are c frame presses for their performance their long-lasting service life. Nadun Machinery's research and development team has more than 10 people, with more than 10 years of experience in field of research and development. Our team is continuously improving innovating to meet evolving marketplace demands.

The company offers the installation commissioning of over 400 clients each year. It manufactures between 500-600 sets of diverse products each year. Our products are certified by ISO, CE and SGS. We are the holder of numerous product innovation patents and honorary certificates recognition of commitment to c frame presses.

To meet the wide market demand cooling solutions, Dragon and Tiger and Temple of Heaven brands offer an array of products that can be customized to a number of different consumers and usage scenarios. With brand building at the primary goal the business, health c frame presses the main focus, and customer experience as the foundation The company is determined to being a top-quality enterprise in the field of health.

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy