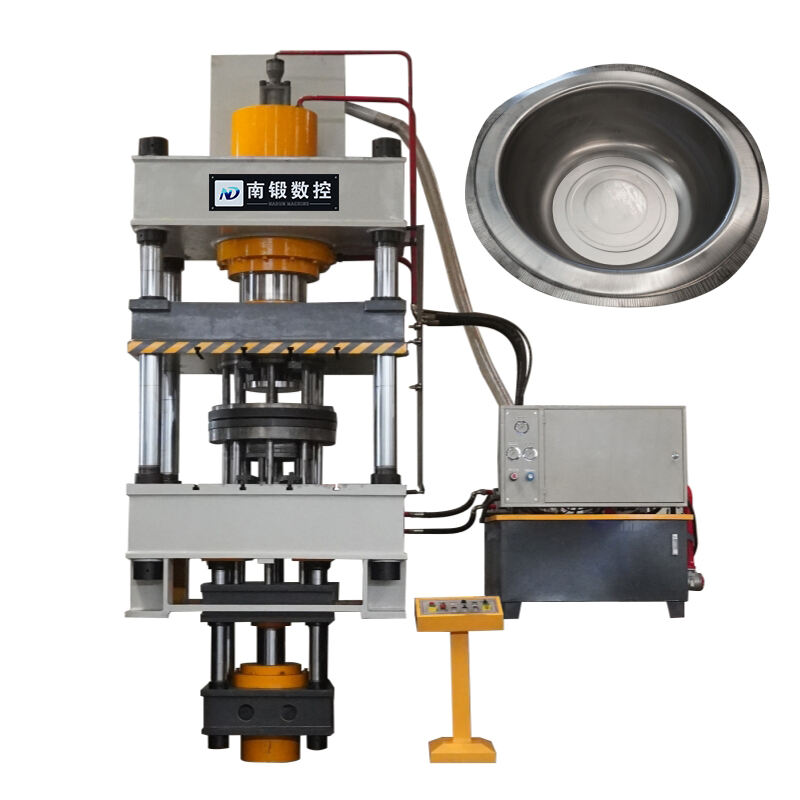

Familiar With the Vertical Hydraulic Press? Sounds tricky, right; but believe it or not; it is a special type of machine that can squeeze and compress all the objects with water or oil. The Nadun brand is one of the manufacturers of good 60 ton hydraulic press on the market. INTRODUCTIONIn this article, we will learn everything about how these machines work, their power, their role in the manufacturing of various products, the crucial machinery that makes them work, and the advantages they present to factories and industries.

While the science behind the working of the vertical hydraulic press may sound complex, it is a basic phenomenon. They use a special pump to build pressure. It is this pressure that allows to squeeze or compress the objects. A hydraulic pump moves a liquid, like oil or even water, through a series of tubes until they build up strength. When the right amount of pressure has build up in the liquid, it is used to push a piston. Indeed, it is this piston that directly compresses the workpiece. How the liquid travels and builds pressure is crucial to how the machine works.

One of the most incredible things about 60 ton presses is the pressure they can create. That remarkable strength is precisely what makes them so valuable for heavy-duty work. Actually, some of the largest vertical hydraulic presses can produce upwards of 5000 tons of pressure! That is an enormous amount of force and sufficient to crush even the hardest substances. Such a capability is what gives these presses their utility as industrial-strength tools in industries where strong materials needs to be shaped or molded.

Vertical hydraulic presses have transformed the production of countless consumer products. And they make a lot of different stuff, including everything from airplane parts to car parts to stuff used to build houses. The force exerted by these presses enables manufacturers to create products that have increased strength and offer greater longevity. This means the products made from them are capable of enduring rigorous conditions which is a very significant requirement in many industries.

To understand how vertical hydraulic presses work, it is crucial to know the details of its constituents. Now, these machines have many important parts. Firstly, there’s the hydraulic pump, which creates the pressure. The liquid is then stored in a reservoir or storage tank, this is to have enough liquid in order to function. The liquid must be transferred from one part of the machine to another, and so there are the pipes and tubes. There may also be a regulator that controls the pressure that is being generated. Finally, the piston or cylinder is the one that do the jobs of compressing or squeezing the things out. All these parts are significant in ensuring the machine is operating correctly.

Hydraulic presses play a crucial role in factories and other manufacturing environments. These machines deliver a heck of a punch, generating huge pressure and are fantastic for producing strong, long-lasting products. It is also highly flexible, which allows for it to be used to manufacture a large number of different item types relative to other industrial resources. Vertical hydraulic presses can also operate quickly and with a high level of precision and are highly efficient machines. It reduces the time in the moratorium and results to productivity. More important is the fact that compression and squeezing objects uses hydraulic power, and it is safer than using any other mechanical method. One of the main advantages in busy factory environments is that there is less risk of injury to workers or damage to the machines.

To meet the wide market demand for cooling items, Dragon and Tiger and Temple Heaven brands offer various products that can be adapted to different customers and use vertical hydraulic press. With brand building as the foundation and health products as the focus, and user experience as the base and the firm is dedicated establishing itself as world-class company in the health sector.

The company provides installation commissioning to more than 400 vertical hydraulic press each year. It manufactures between 500 and 600 sets diverse products each year. These products have been certified by ISO, CE and SGS. Our commitment to excellence is reflected in many product innovation patents we hold the honorary certificates we've received.

Nadun Machinery is known for its high-quality vertical hydraulic press with outstanding performance, and long-lasting durability of their service. Nadun Machinery is researchers and developers of more than ten people each with an average of more than 10 years experience in research and development. They are constantly innovating developing our products to satisfy the needs of the market.

Nadun Machinery is a leading manufacturer and exporter of metal processing equipment over 17 years' experience. We focus on punch presses, hydraulic presses shearing machines, bending machines and vertical lathes caters numerous industries, including aerospace, automotive manufacturing, mechanical engineering, construction, and metallurgical engineering. Our products are sold in 150+ countries and regions globally and are setting new vertical hydraulic press in manufacturing machinery.

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy