|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Nadun |

|

Model Number: |

YM-630T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

With its high rigidity, high precision, strong resistance to off-loading and automation advantages, the Frame Hydraulic Press occupies a core position in the fields of metal/non-metal molding and composite material molding.

Structural features: Adopting overall welded frame structure, the machine body is welded by high-strength steel plate, which is tempered and vibrated to eliminate internal stress, ensuring high rigidity and deformation resistance. Quadrangle eight-face guide rail guide design, slider repeatable positioning accuracy, parallel accuracy, strong resistance to partial load, suitable for large size, high strength workpiece processing.

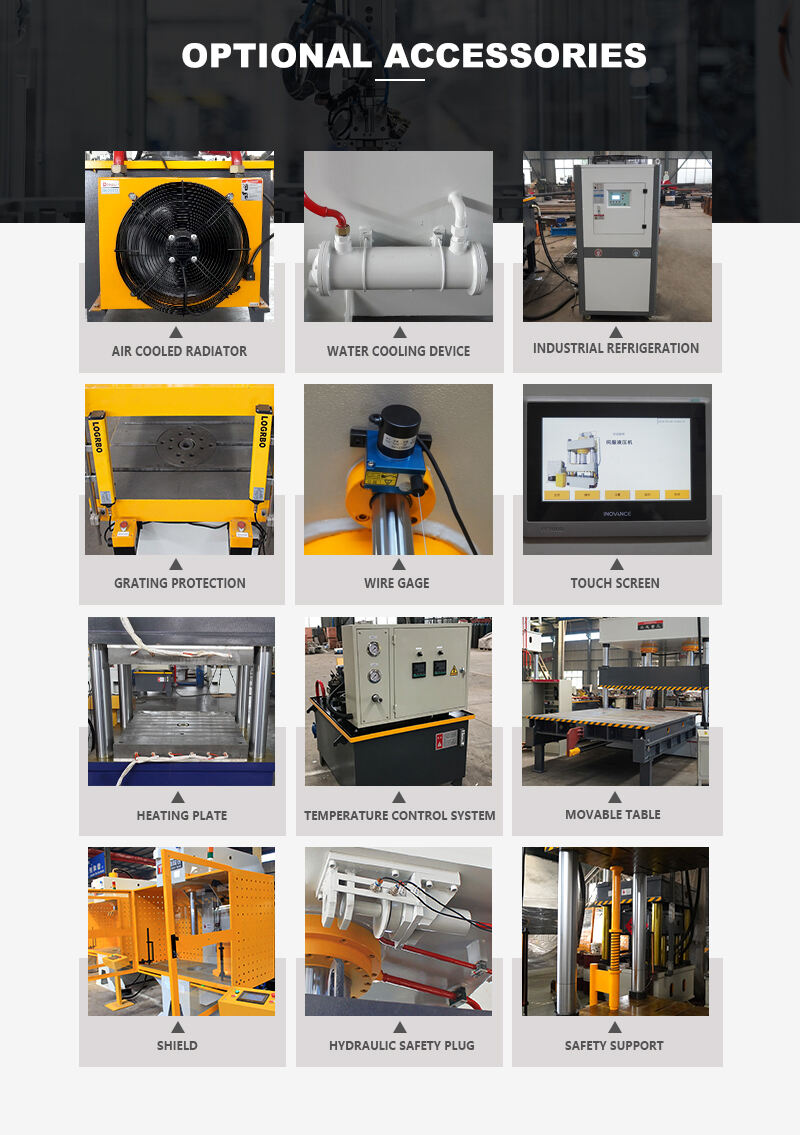

Hydraulic system: integrated cartridge valve technology, pressure fluctuation ≤ ± 2%, with servo motor to realize energy saving 20-50%. The system is equipped with pressure relay overload protection, hydraulic locking and mechanical block double fall prevention device, safety is significantly improved.

Control system: PLC + HMI human-machine interface, support for fixed-pressure/fixed-travel dual-mode, can be preset pressure, speed, stroke parameters, to achieve automated production. Equipped with safety light curtain (response time 16ms), emergency stop button and safety interlocking device, operation risk is reduced.

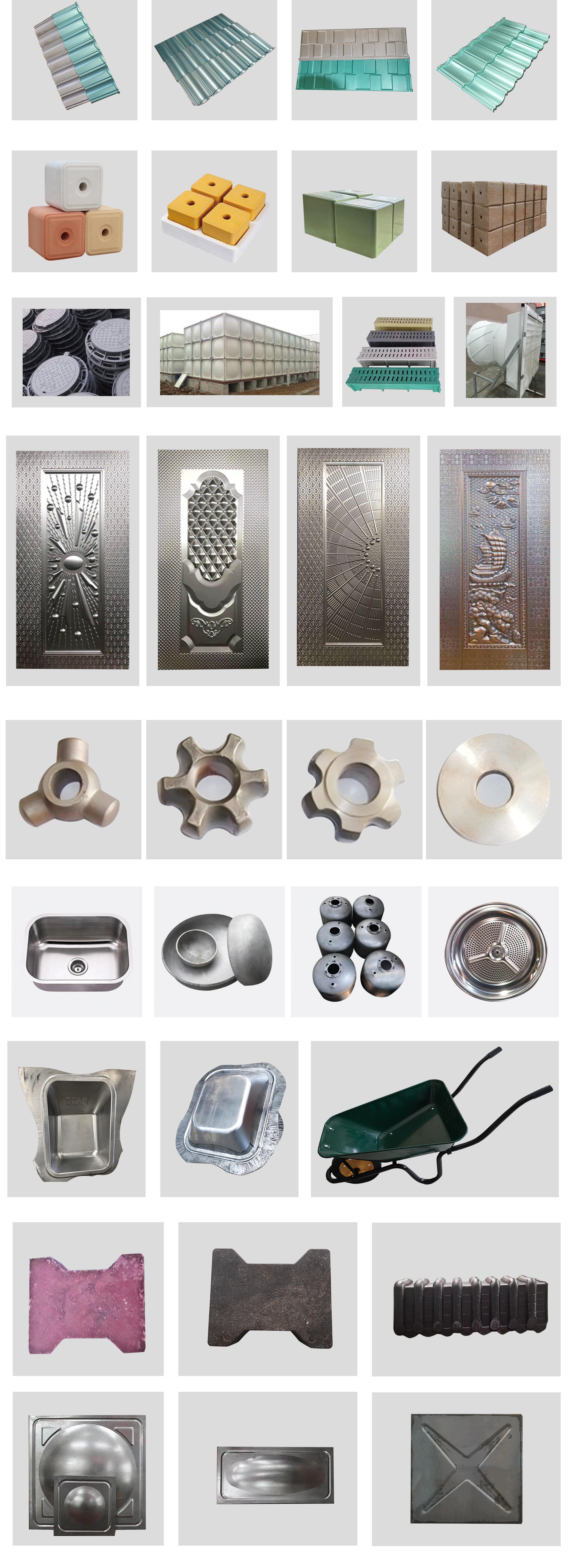

Metal processing: automotive parts (body covering parts, cabin structural parts), mold pressing (plastic/stamping/die-casting molds), powder metallurgy (high-density metal products), aerospace (structural parts molding), shipbuilding (large-size plate processing).

Non-metallic molding: plastic products (automotive bumpers, appliance housings), composite material molding (carbon fiber, fiberglass), rubber product pressing.

Special process: shallow stretching, bending, flanging, punching and cutting drop, straightening, press fitting, etc., suitable for the production of automotive interior parts, kitchen utensils, hardware parts, etc.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy